Impeller penetration flaw detection platform

A technology of penetrant flaw detection and work platform, which is applied in the direction of optical testing for flaws/defects, chemical instruments and methods, cleaning methods and utensils, etc. It can solve the problem of difficult cleaning of blades, complex shape of impeller surface, and easy scratching of inspectors, etc. problems, achieve the effects of reducing labor intensity, preventing sewage backsplash, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

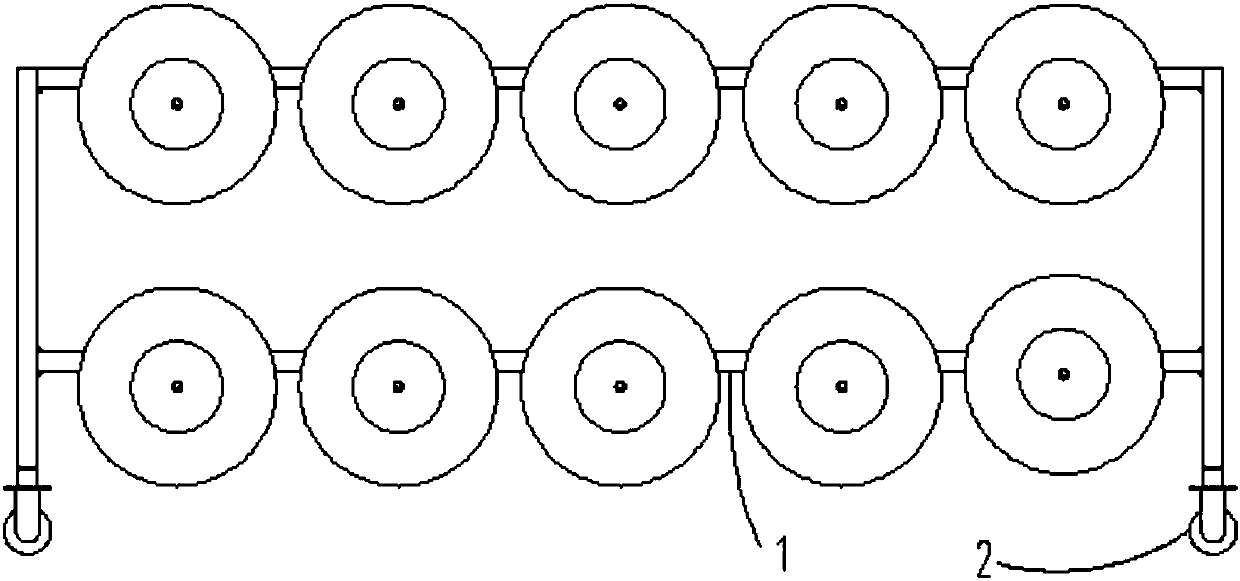

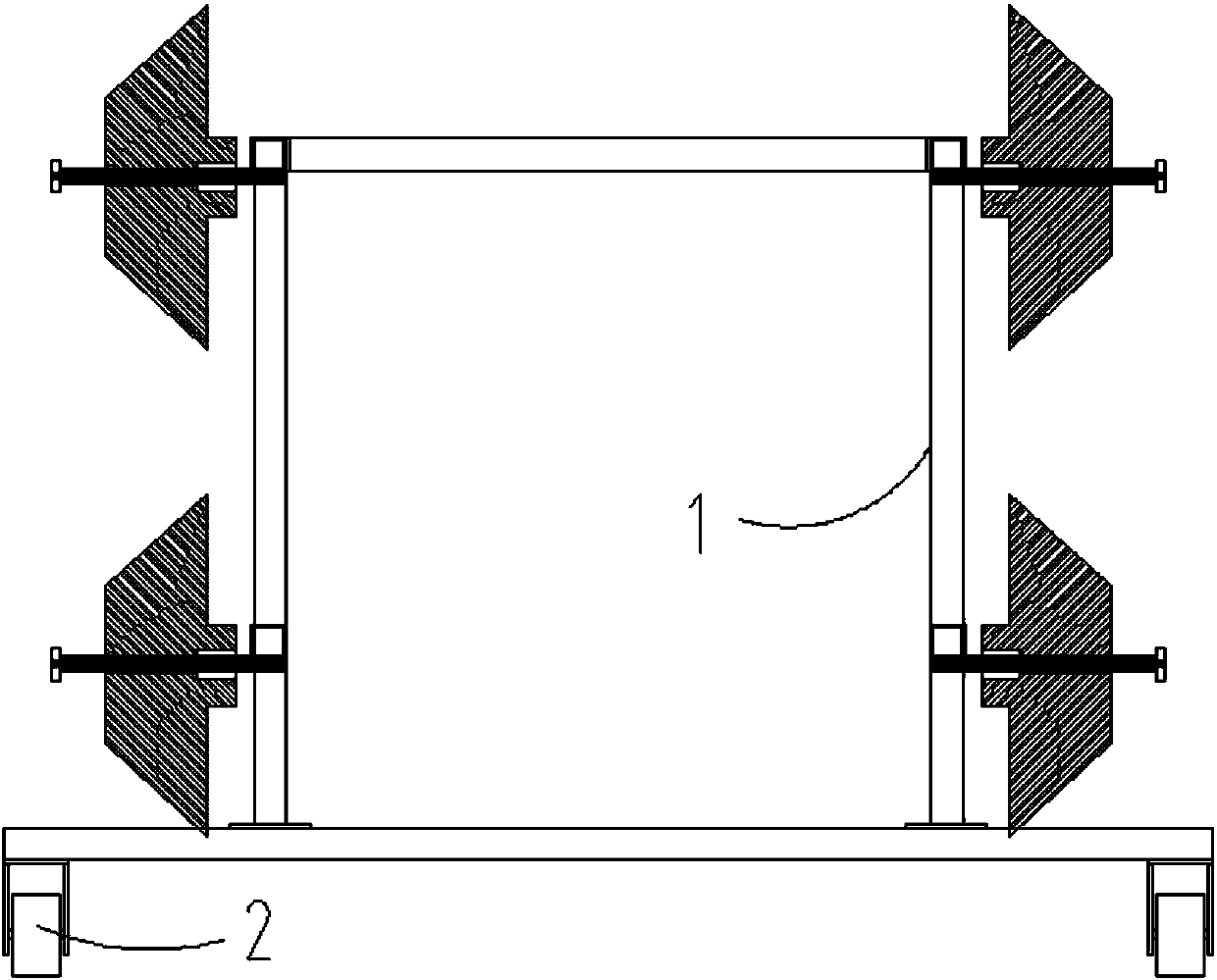

[0013] Such as Figure 1 to Figure 3 , the invention discloses an impeller penetrant flaw detection work platform, comprising a high-pressure cleaner and a cleaning frame, the high-pressure cleaner is arranged on one side of the cleaning frame, and the impeller is hung on the cleaning frame.

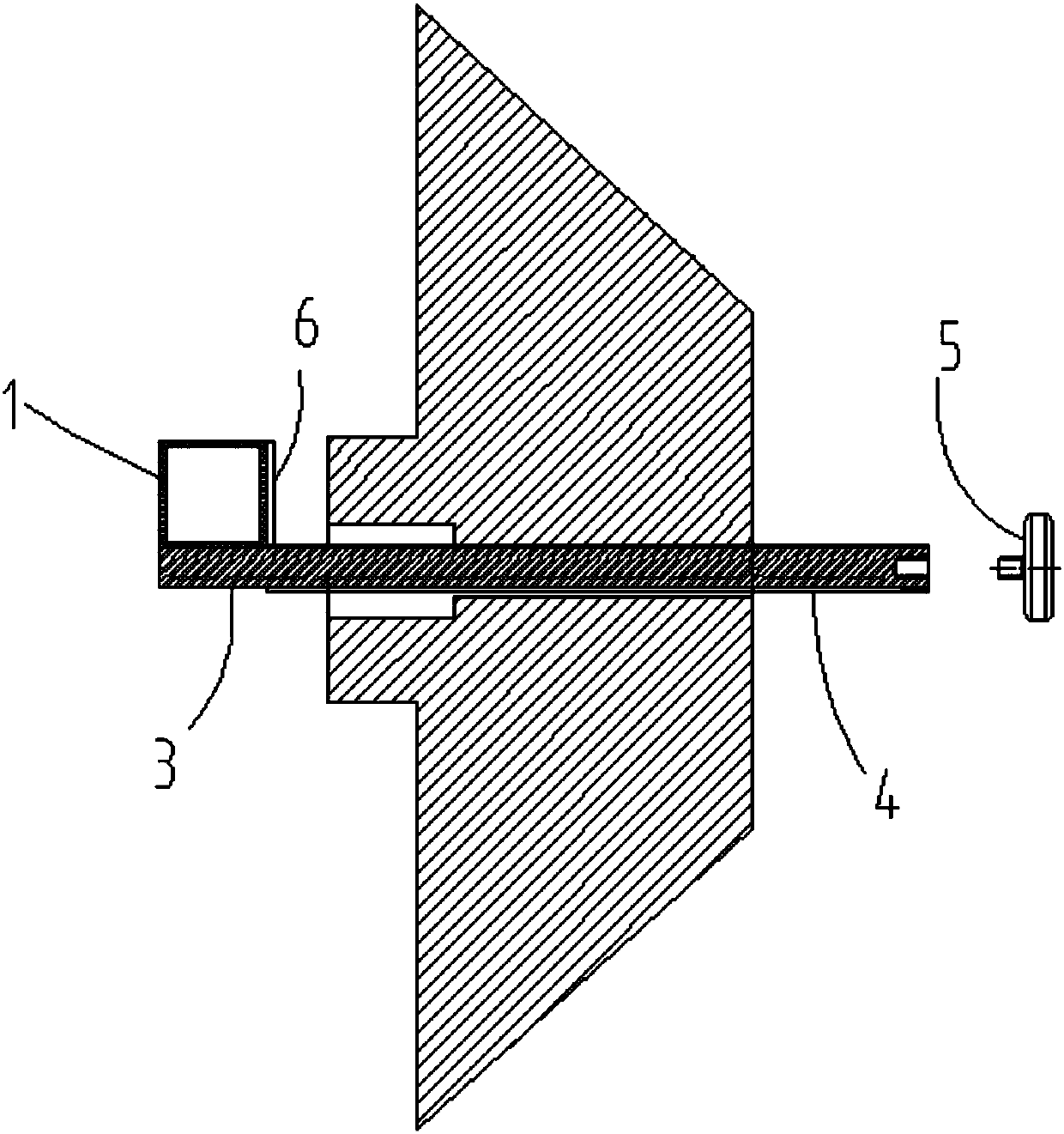

[0014] The cleaning frame includes a frame body 1, a universal wheel 2, a hanging rod 3, a heat-shrinkable tube 4 and a cover 5, several hanging rods 3 are welded horizontally on the frame body 1, and the heat-shrinkable tube 4 is set on the hanging rod 3. The cover 5 is screwed to the end of the hanging rod 3, and the universal wheel 2 is arranged at the bottom of the frame body 1.

[0015] In order to better protect the impeller, a rubber pad 6 is provided on the frame body 1 and on one side of the hanging rod 3 .

[0016] The block cover 5 is made of aluminum alloy with high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com