A four-stroke engine

一种四冲程发动机、阀驱动的技术,应用在发动机元件、燃烧发动机、发动机的润滑等方向,能够解决系统易损坏等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

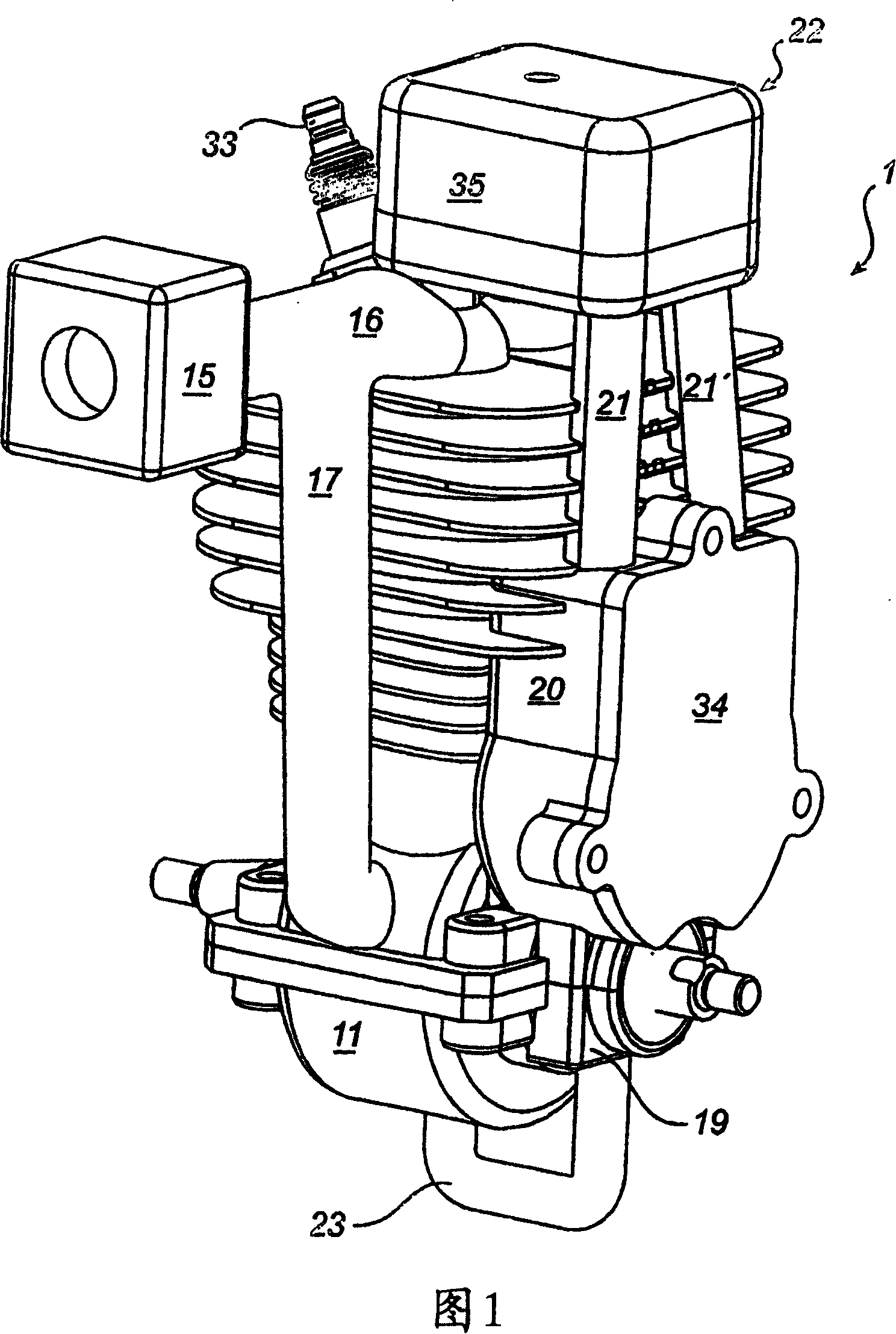

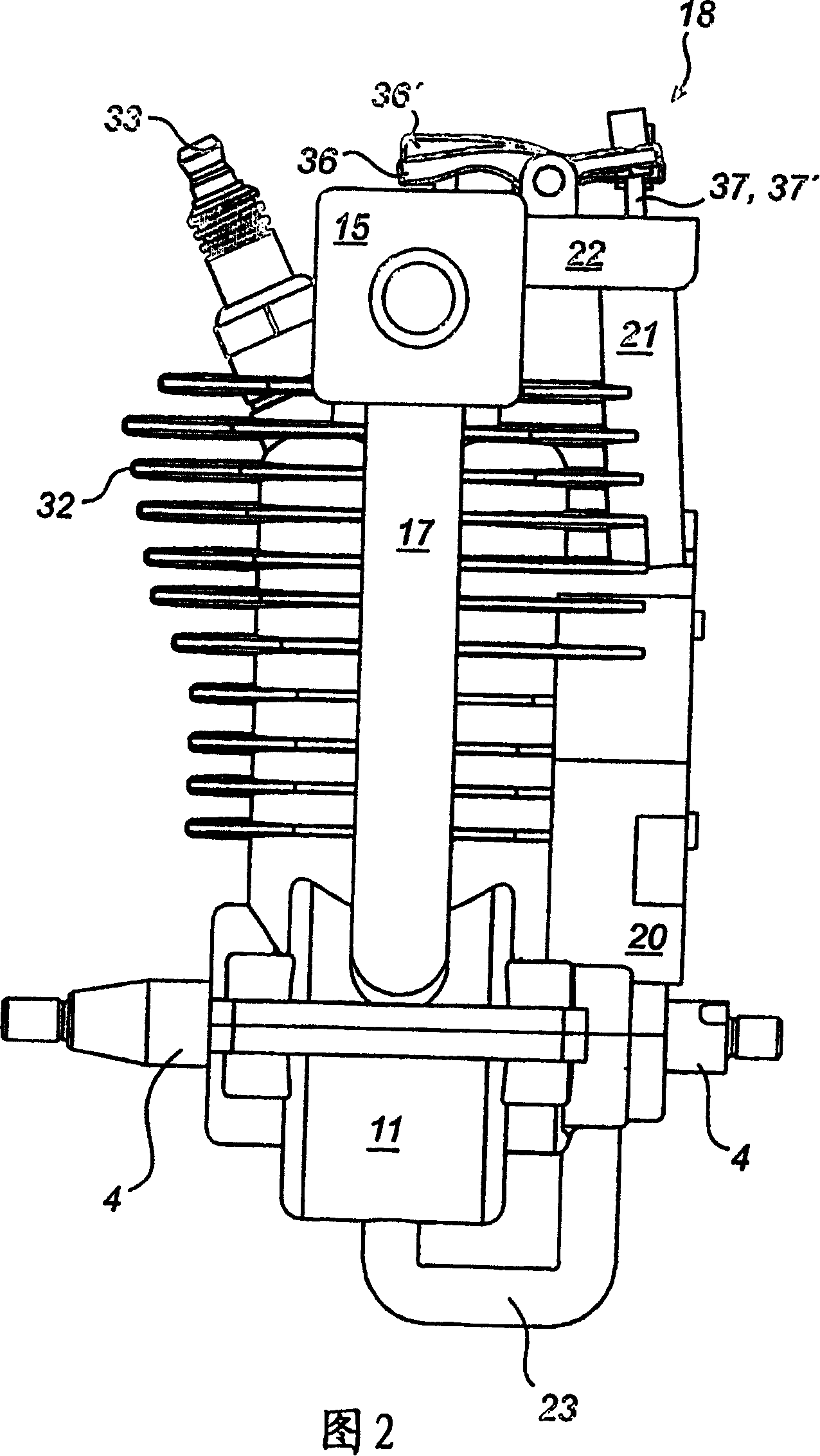

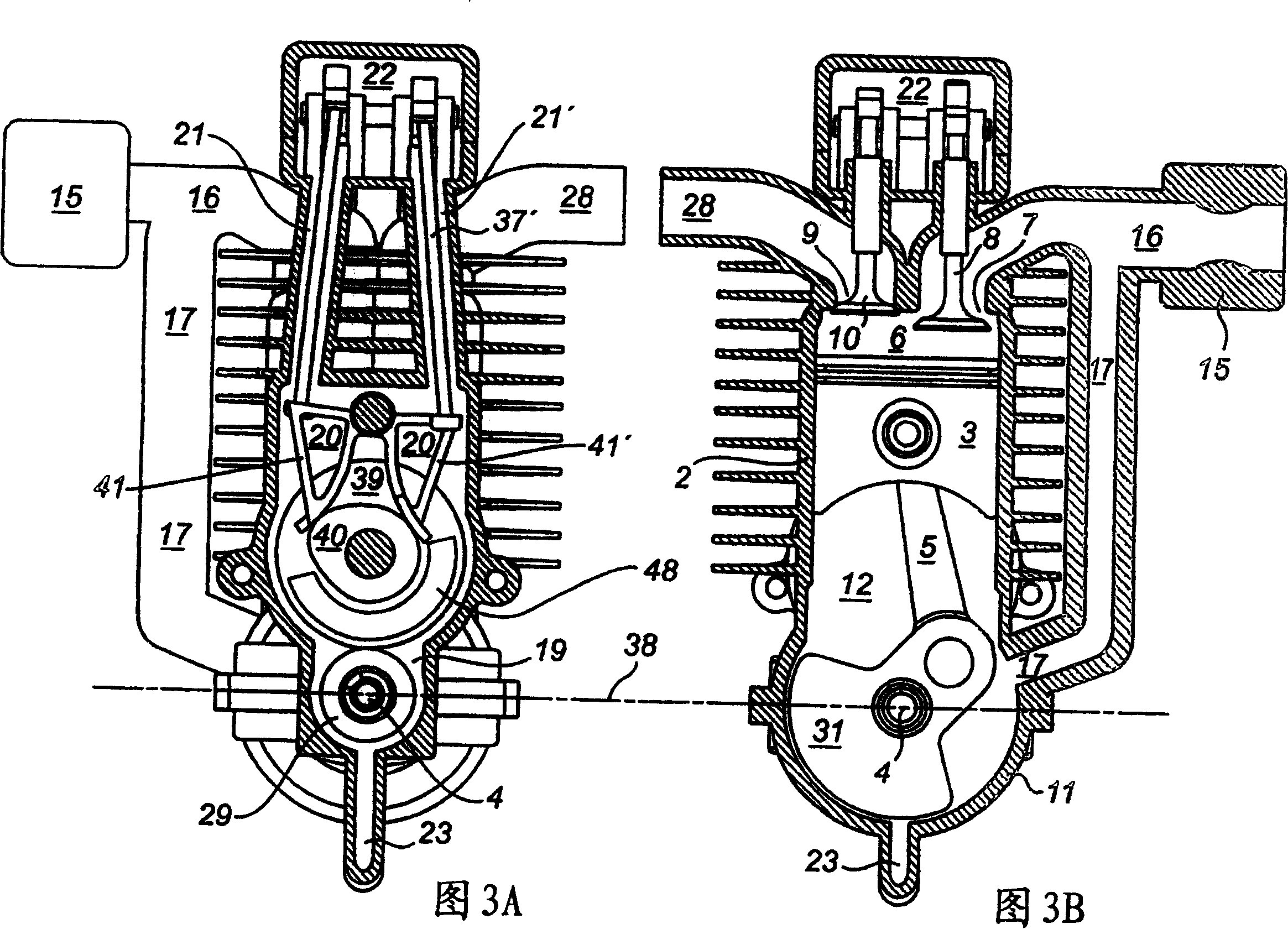

[0025] FIG. 1 shows a crankcase-scavenged four-stroke engine 1 according to the invention in a perspective view. The engine has a cylinder 2 with cooling fins 32 and spark plugs 33 . Crankcase 11 is connected below cylinder 2. The intake passage 16 is connected with the intake port (7) with the intake valve (8). A mixture preparation device 15 for proper supply of the air-fuel-lubricant mixture is provided on the intake passage 16 . The gas mixture preparation device supplies at least air 13 and lubricant 14 to the air inlet and connecting pipe 17 . This will be described more fully with reference to Figures 3A and 3B. The valve drive assembly 18 is sealed in a valve drive assembly housing 19 , 20 , 21 , 21 ′, 22 .

[0026] A passage 23 connects between the crankcase 11 and the lowermost portion 19 of the valve drive assembly housing. The second lowest portion of the valve drive assembly housing 20 is covered by a cover 34 . The top 22 of the module housing is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com