Device for preventing backwash liquid from polluting wafer

A wafer and liquid technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as wafer contamination, and achieve the effects of low cost, simple structure, and improved cleanliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

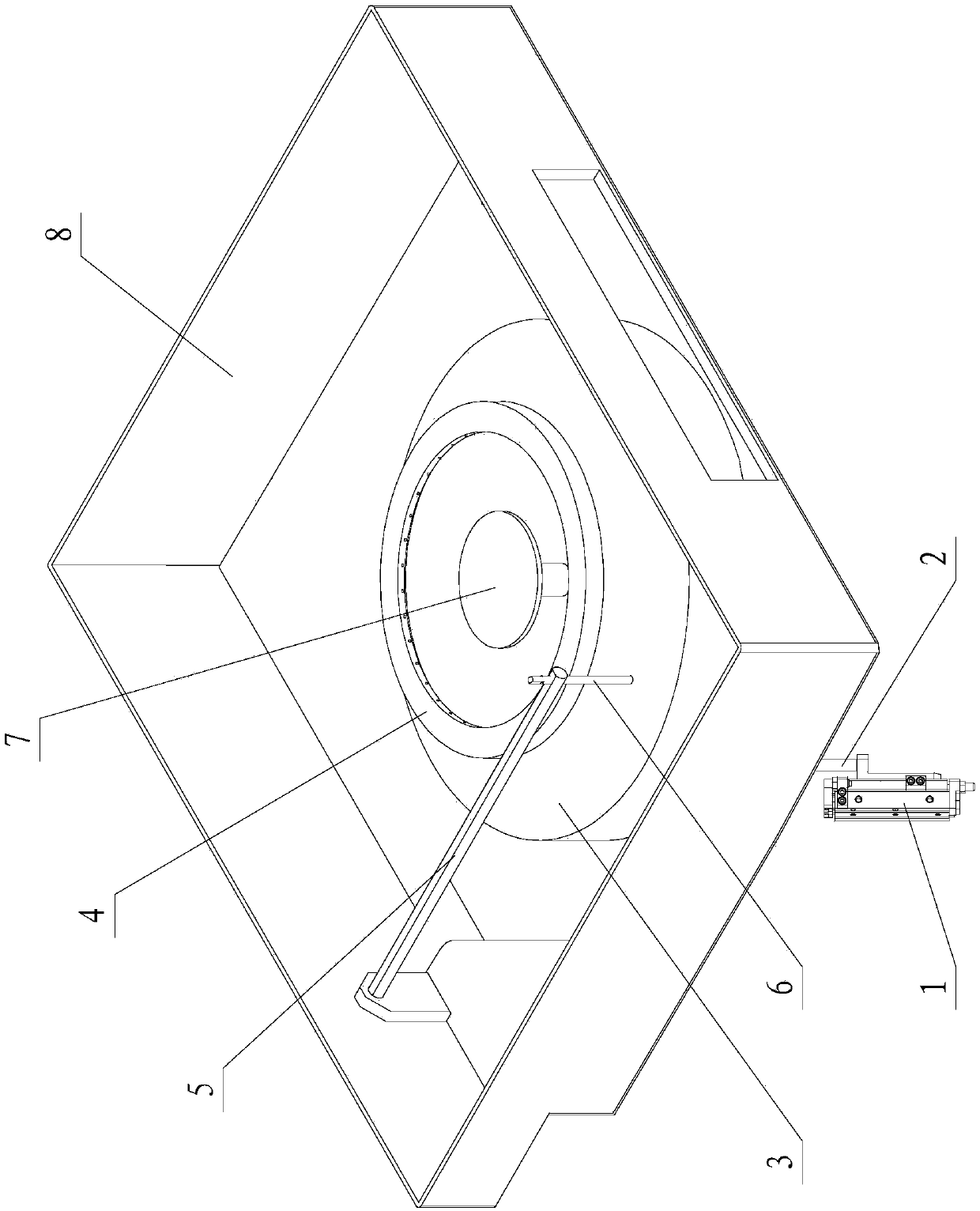

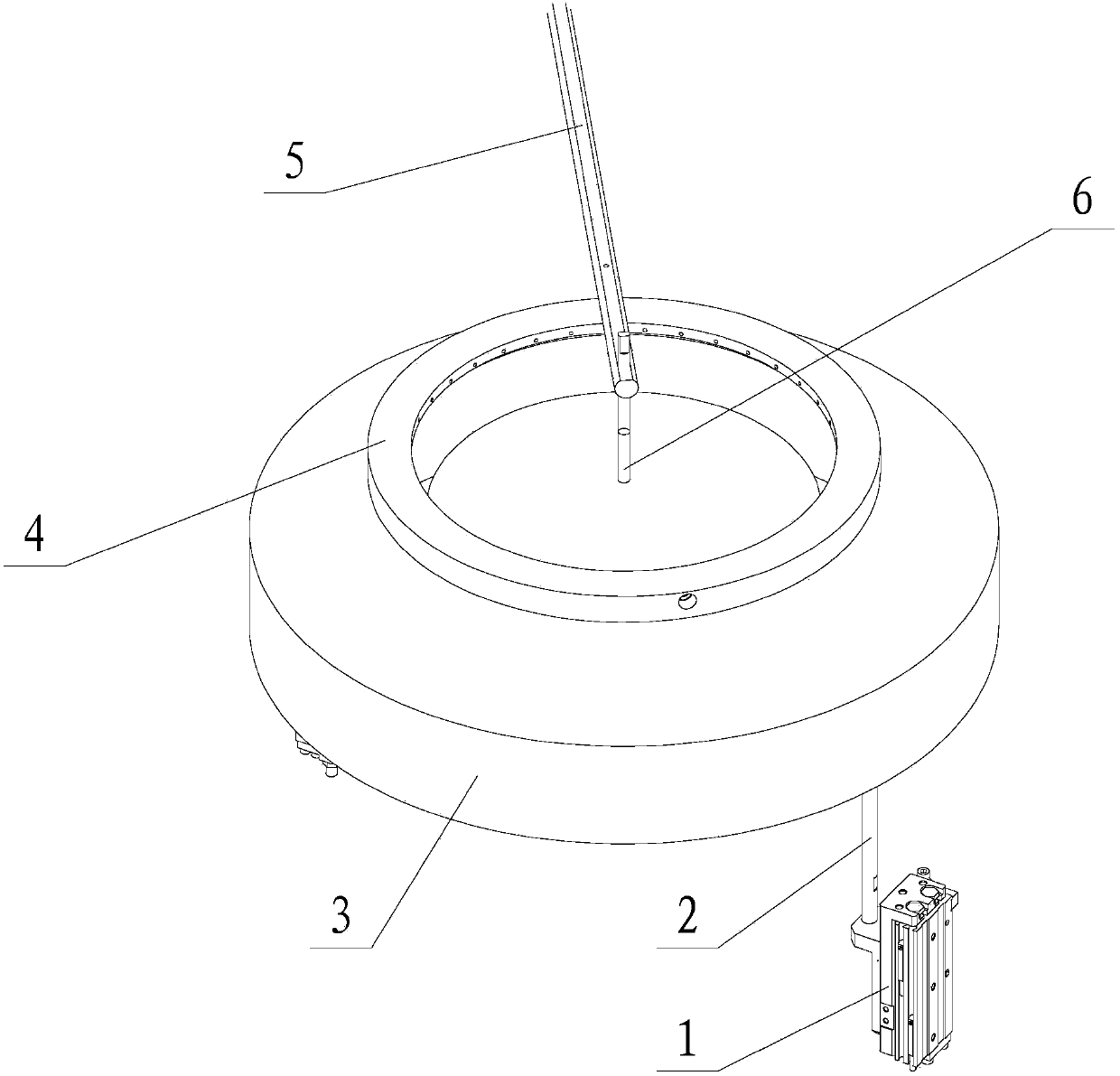

[0020] Such as figure 1 As shown, the present invention includes a power source 1, a lifting connecting rod 2, a lifting CUP3, a gas protection ring 4, a swing arm 5, a nozzle 6, a wafer table 7 and a process chamber 8, the lifting CUP3, the swing arm 5, and the nozzle 6 and the film holder 7 are all located in the process chamber 8, the power source 1 is installed below the process chamber 8, which can be a cylinder or a motor; the output end of the power source 1 is connected with a lifting connecting rod 2, and can drive the lifting connecting rod 2 Complete the lifting action according to the process requirements. The nozzle 6 is installed on the swing arm 5 and swings back and forth with the swing arm 5 .

[0021] Lifting CUP3 is a circular structure with variable diameter, that is, the top is truncated cone and the bottom is cylindrical. The wafer car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com