Fuse element assembly

A technology for fuse elements and components, applied in electrical components, circuits, emergency protection devices, etc., can solve the problems of complex components, inability to overcome the problem of jetting, the final damage of fuse lines, and increasing the physical size of full-scale fuses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

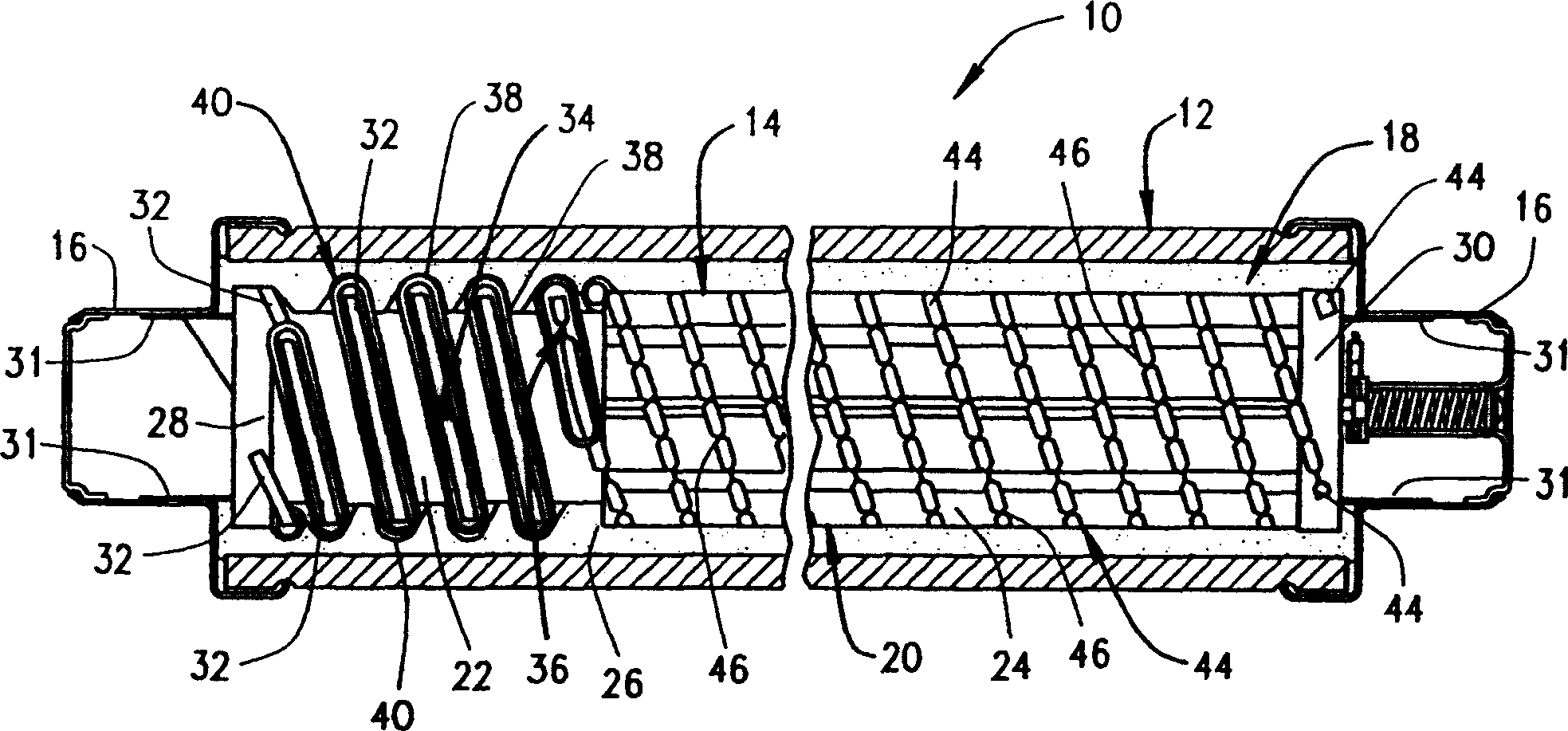

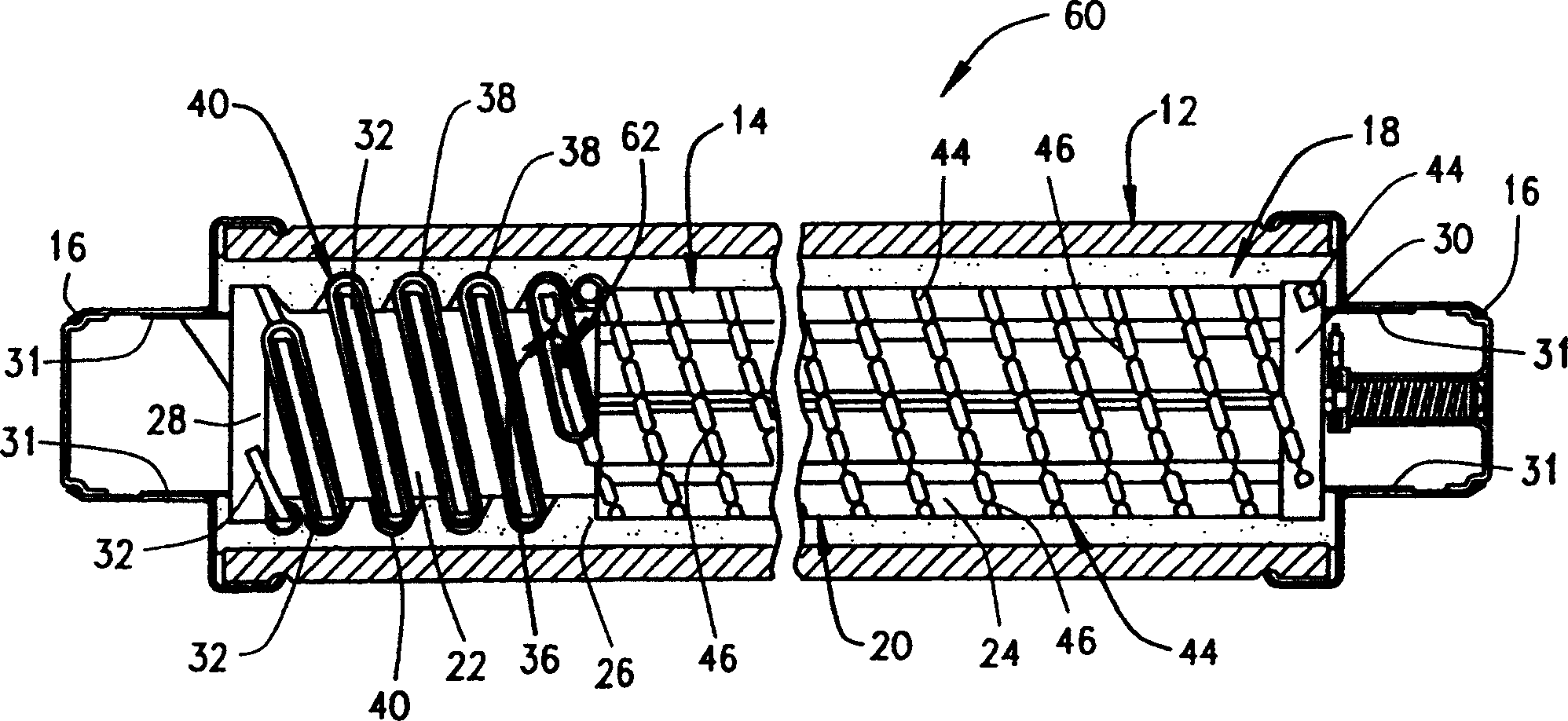

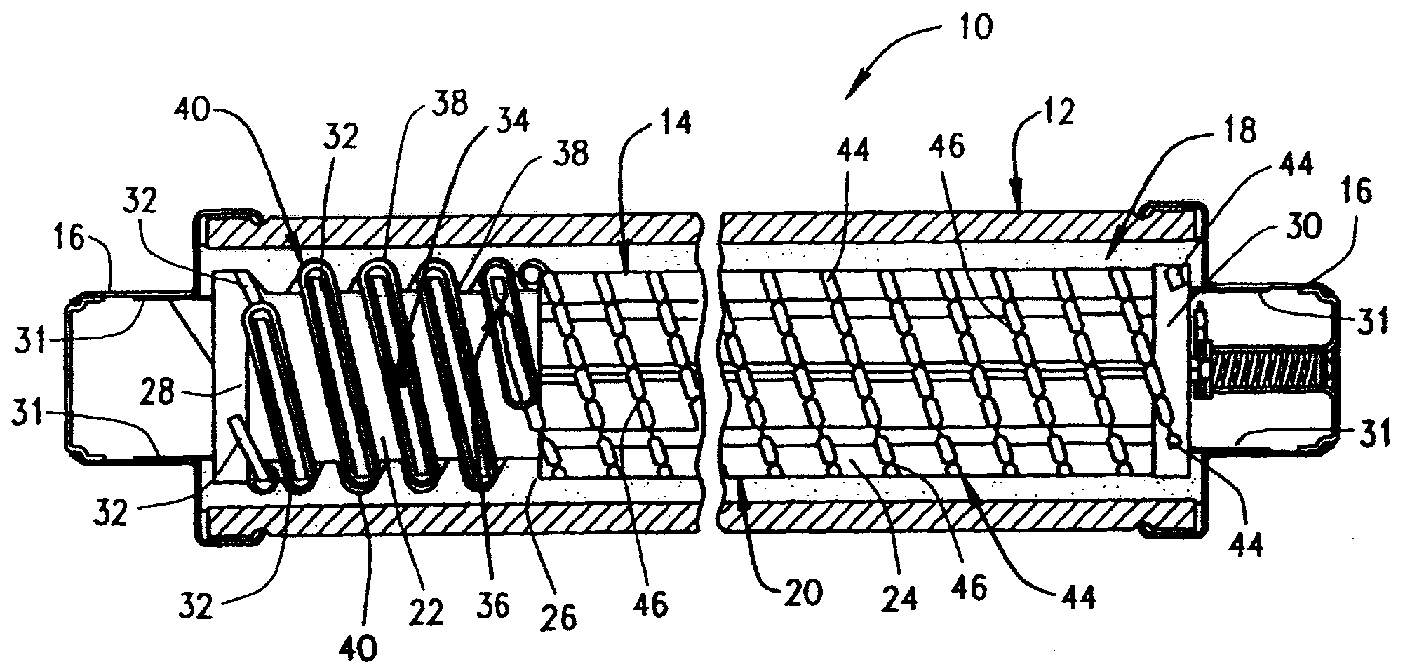

[0014] figure 1 The illustrated full range fuse 10 includes an insulating fuse body 12, a fuse element assembly 14 within the body 12, a conductive end cap 16 coupled to the closed body 12 and electrically connected to the fuse element assembly 14, and a Arc extinguishing material 18 surrounds the fuse element assembly 14 within the body 12 . Thus, when end cap 16 is connected to an energized circuit (not shown), fuse 10 completes an electrical circuit through fuse element assembly 14 . When the current flowing through the fuse 10 approaches an unacceptable level, the fuse element assembly 14 at least partially operates, melts, vaporizes, or opens, depending on the characteristics of the fuse element assembly 14 and thus the current rating of the fuse 10 , thereby limiting the current and interrupting the damaging current flowing through the fuse 10, as detailed below. Therefore, the circuit and equipment on the connection side can be electrically isolated from the faulty lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com