Concrete piles

A technology of concrete piles and inverted cones, which is applied to sheet pile walls, earthwork drilling, drilling equipment, etc., can solve the problems of increasing concrete consumption and concrete waste, saving consumption, improving the bearing capacity of piles, and reducing engineering costs. The effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

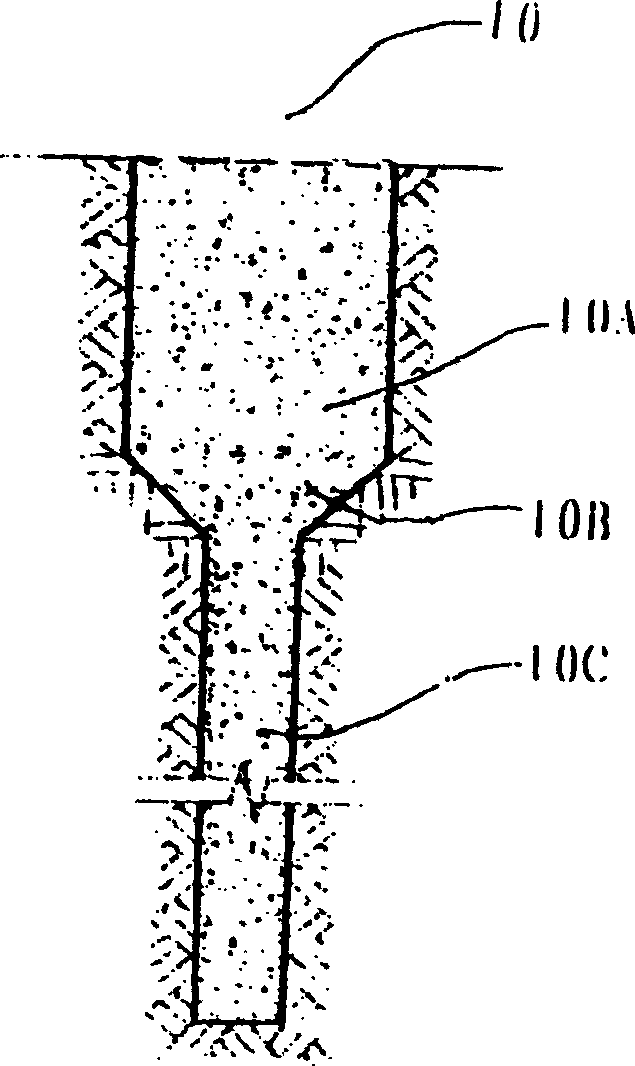

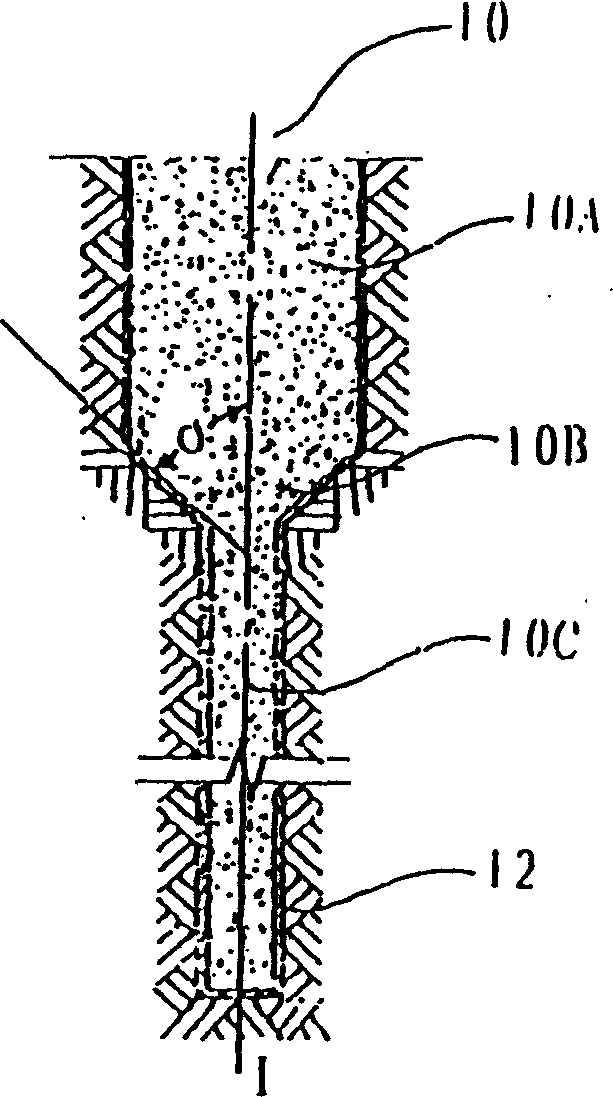

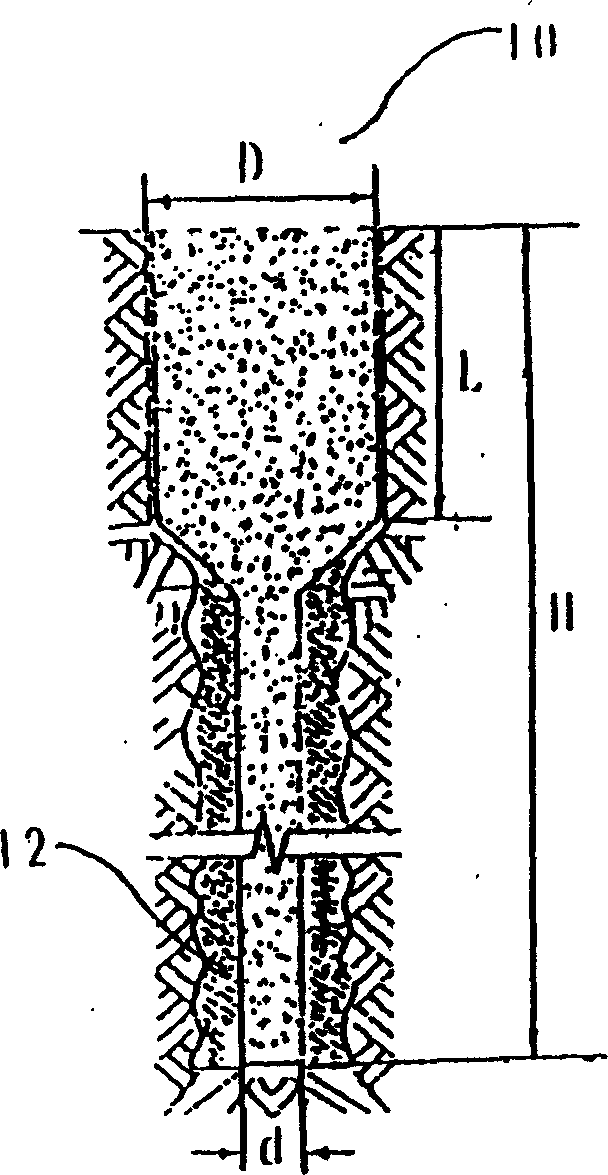

[0015] Fig. 1(a)-(d) respectively describe concrete piles of different structures of the present invention. As can be clearly seen from these accompanying drawings, the common feature of the concrete pile 10 of the present invention is: it is made up of an upper part 10A, a lower part 10C and a middle part 10B connecting the upper part 10A and the lower part 10C, and the diameter of the upper part 10A is larger than that of the lower part 10C. diameter, and the ratio of D:d is 1.2 to 8:1. The middle part 10B connecting the upper part 10A and the lower part 10C is an inverted cone with a small bottom and a large top. The maximum diameter of the inverted cone is equal to the diameter D of the upper part 10A, and the minimum diameter of the inverted cone is equal to the diameter d of the lower part 10C.

[0016] The depth L of the upper portion 10A is typically greater than 0.1 meters. As shown in Figure 1(b), the middle part 10B is in the shape of an inverted truncated cone, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com