Production for stable chlorinedioxide solution

A chlorine dioxide and production method technology, applied in the direction of chlorine dioxide, etc., can solve the problems of difficulty in producing high-concentration, high-purity stable chlorine dioxide solution, difficult accurate control of process operation, difficult control of reaction process, etc., to achieve stable Continuous operation process, complete conversion of raw materials, and the effect of solving instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

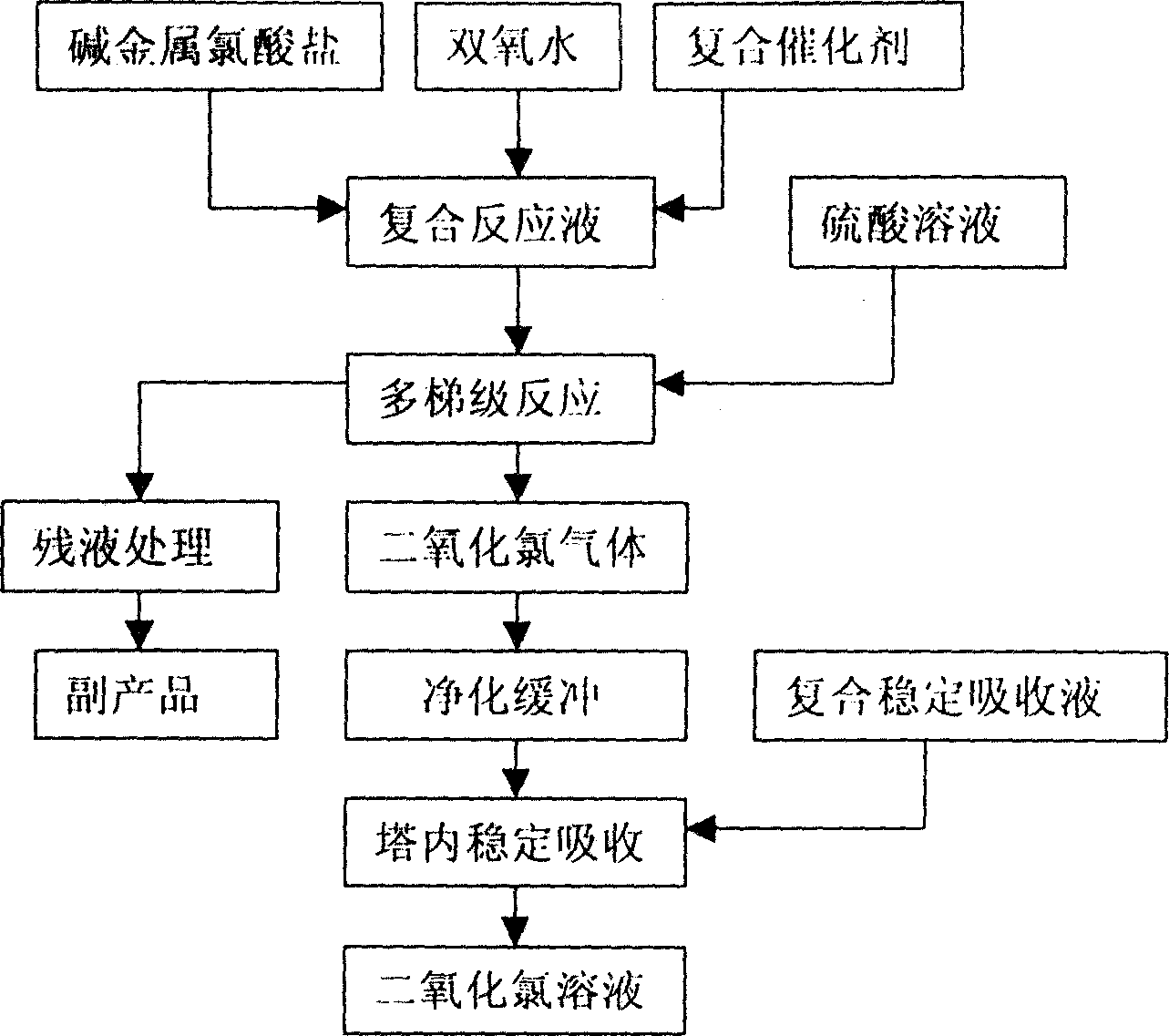

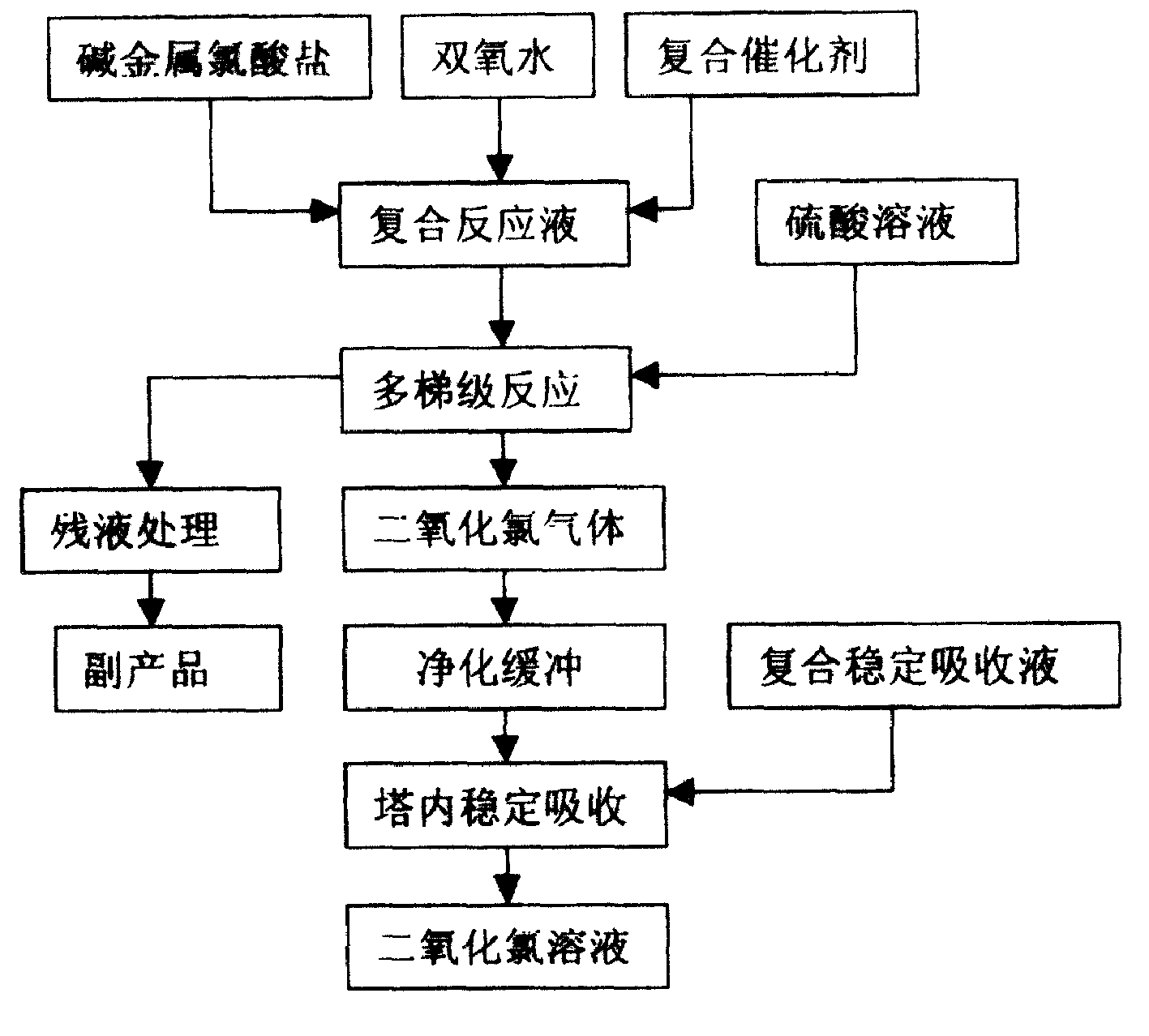

Method used

Image

Examples

Embodiment 1

[0025] The production product specification concentration was determined to be 2%. First, sodium pyrophosphate, 2-hydroxyphosphonoacetic acid, and urea are made into a composite catalyst in a weight ratio of 1:0.4:0.7; The solution (30%) and the composite catalyst were continuously stirred at normal temperature to be completely dissolved as a composite reaction solution, and the weight ratio of sodium chlorate, hydrogen peroxide, demineralized water and composite catalyst was 1: 0.7: 0.7: 0.008; The composite stable absorption liquid is added to the absorption tower, and the proportions are: sodium carbonate 3.5%; sodium hydroxide 0.5%; hydrogen peroxide 5%; deionized water 91%; , the reaction temperature is 32~35C. After running for 8 hours, 1.15 tons of stable chlorine dioxide aqueous solution was discharged. The calculated raw material consumption cost was 342 yuan per ton of product, the total yield was 89.1%, and the purity of chlorine dioxide in the product was 98.5% me...

Embodiment 2

[0028] The product specification concentration was determined to be 4%. Get the weight proportioning of composite catalyst sodium pyrophosphate, 2-hydroxy acetic acid, urea to be 1: 0.4: 0.6; in the composite reaction solution, the weight ratio of sodium chlorate, hydrogen peroxide, demineralized water and composite catalyst is 1: 0.4: 0.6: 0.65:0.76:0.008; add composite stable absorption liquid to the combined absorption tower, the ratio is sodium carbonate 4%; sodium hydroxide 1%; hydrogen peroxide 8%; deionized water 87%, hydrogen peroxide concentration 30% , adjust the flow rate of the composite reaction liquid to 22L / h, the flow rate of sulfuric acid solution to 26L / h, control the reaction negative pressure of the multi-step reactor at 0.04~0.42Mpa, and the reaction temperature at 32~35℃. After running for 15 hours, 3.07 tons of stable chlorine dioxide aqueous solution was discharged. The calculated raw material consumption cost was 703 yuan per ton of product, the total ...

Embodiment 3

[0030] The product specification concentration was determined to be 8%. The weight ratio of composite catalyst sodium pyrophosphate, 2-hydroxypyranoyl acetic acid and urea is 1: 0.5: 0.1; the weight ratio of sodium chlorate, hydrogen peroxide, demineralized water and composite catalyst in the composite reaction solution is 1: 0.65 : 0.8: 0.008; add composite stable absorption liquid to the combined absorption tower, and the ratio is 5% sodium carbonate; 4.5% sodium hydroxide; 16% hydrogen peroxide; 74.5% deionized water; L / h, the flow rate of sulfuric acid solution is 18.5L / h; the flow rate of pure water is 14L / h; the reaction negative pressure of the multi-step reactor is controlled at 0.04-0.42Mpa, and the reaction temperature is 32-35°C. After running for 8 hours, 1.08 tons of stable chlorine dioxide aqueous solution was discharged, and the calculated raw material consumption cost was 1448 yuan per ton of product, the total yield was 87.9%, and the purity of chlorine dioxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com