Substrate processing devices

A substrate processing device and substrate technology, applied in thin material processing, transportation and packaging, optics, etc., can solve the problems that cannot be eliminated, cannot be uniformly attached by etching liquid, and cannot completely avoid stains, so as to prevent liquid from scattering and solve equipment problems. Etching problem, effect of preventing drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

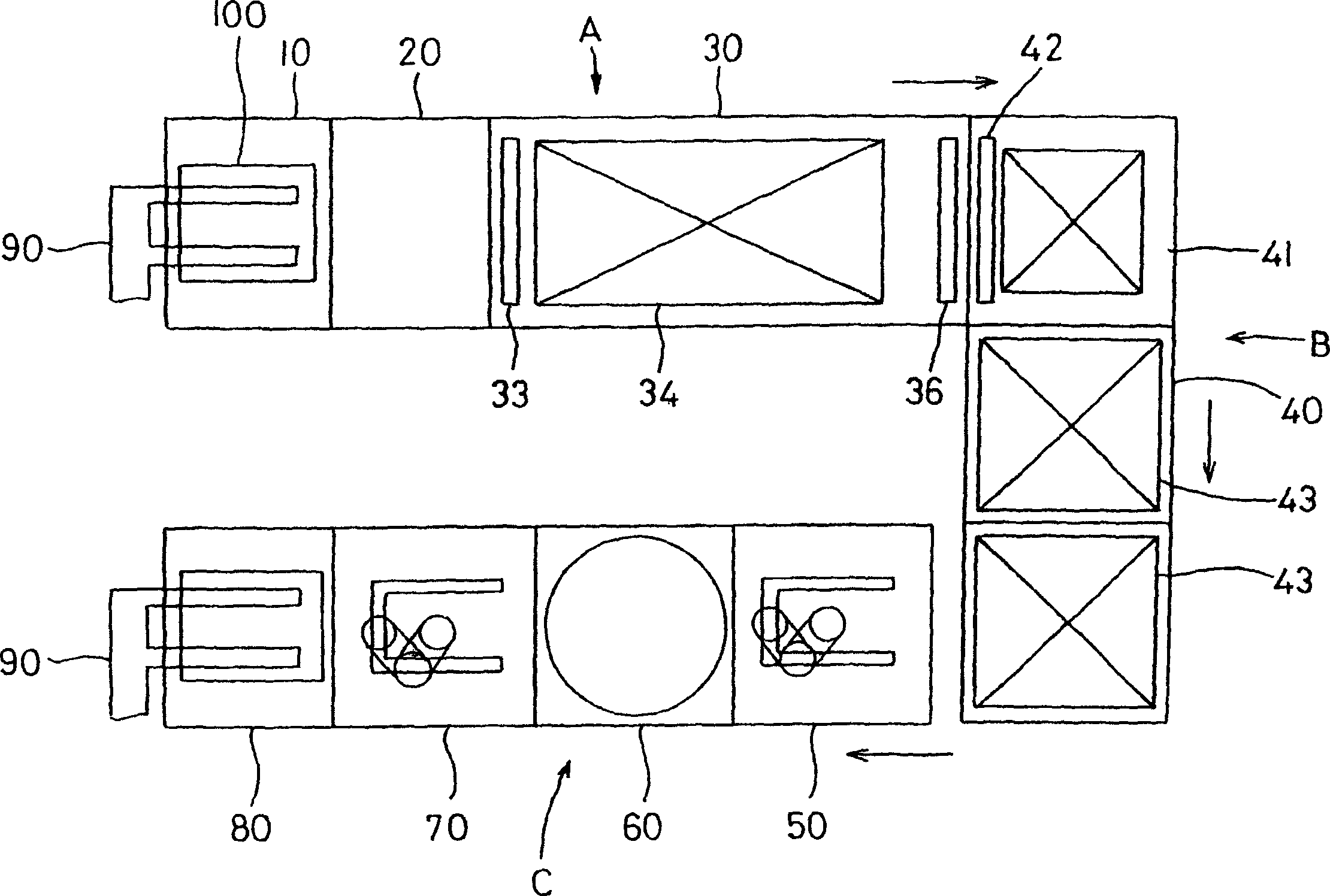

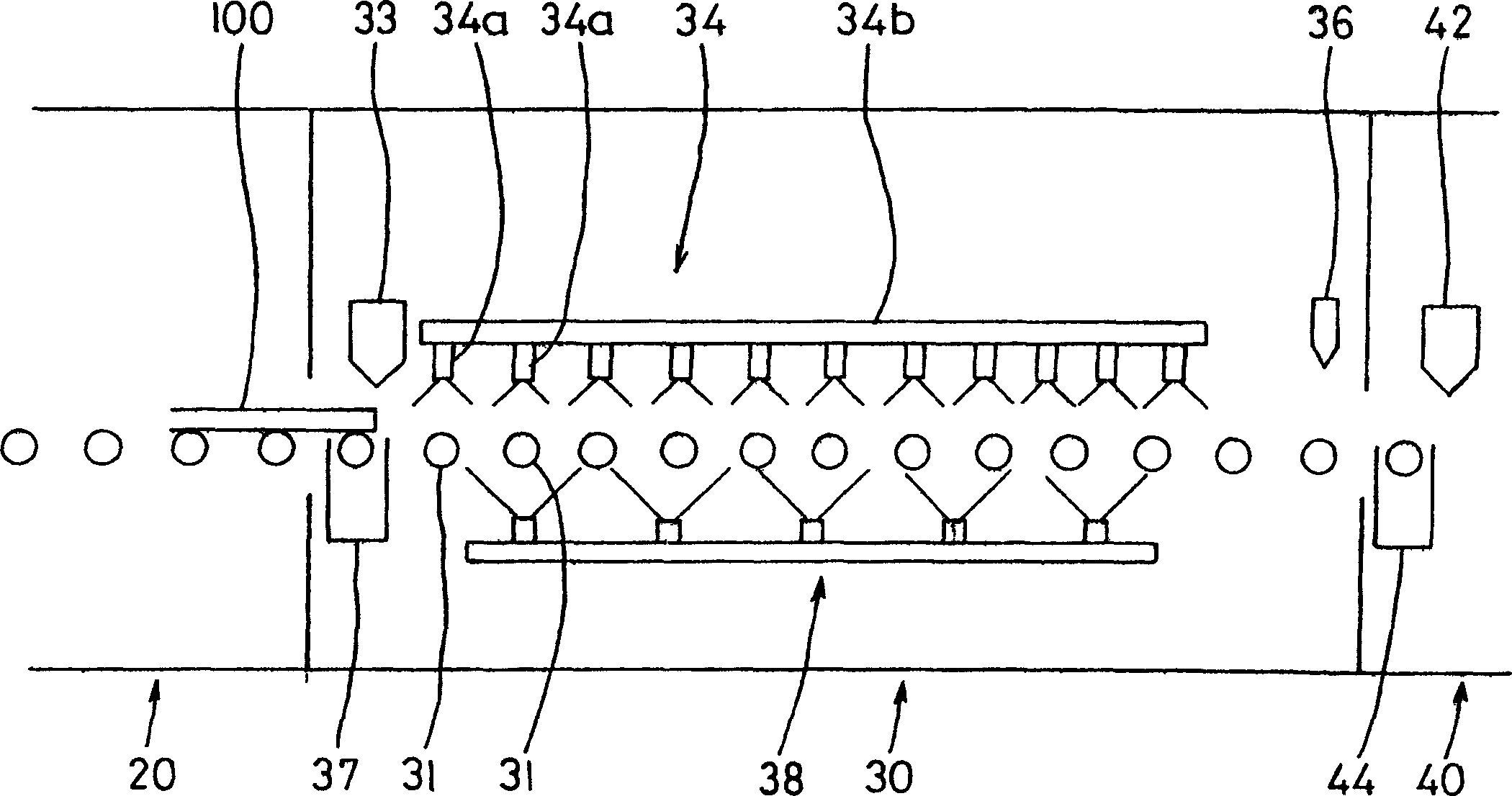

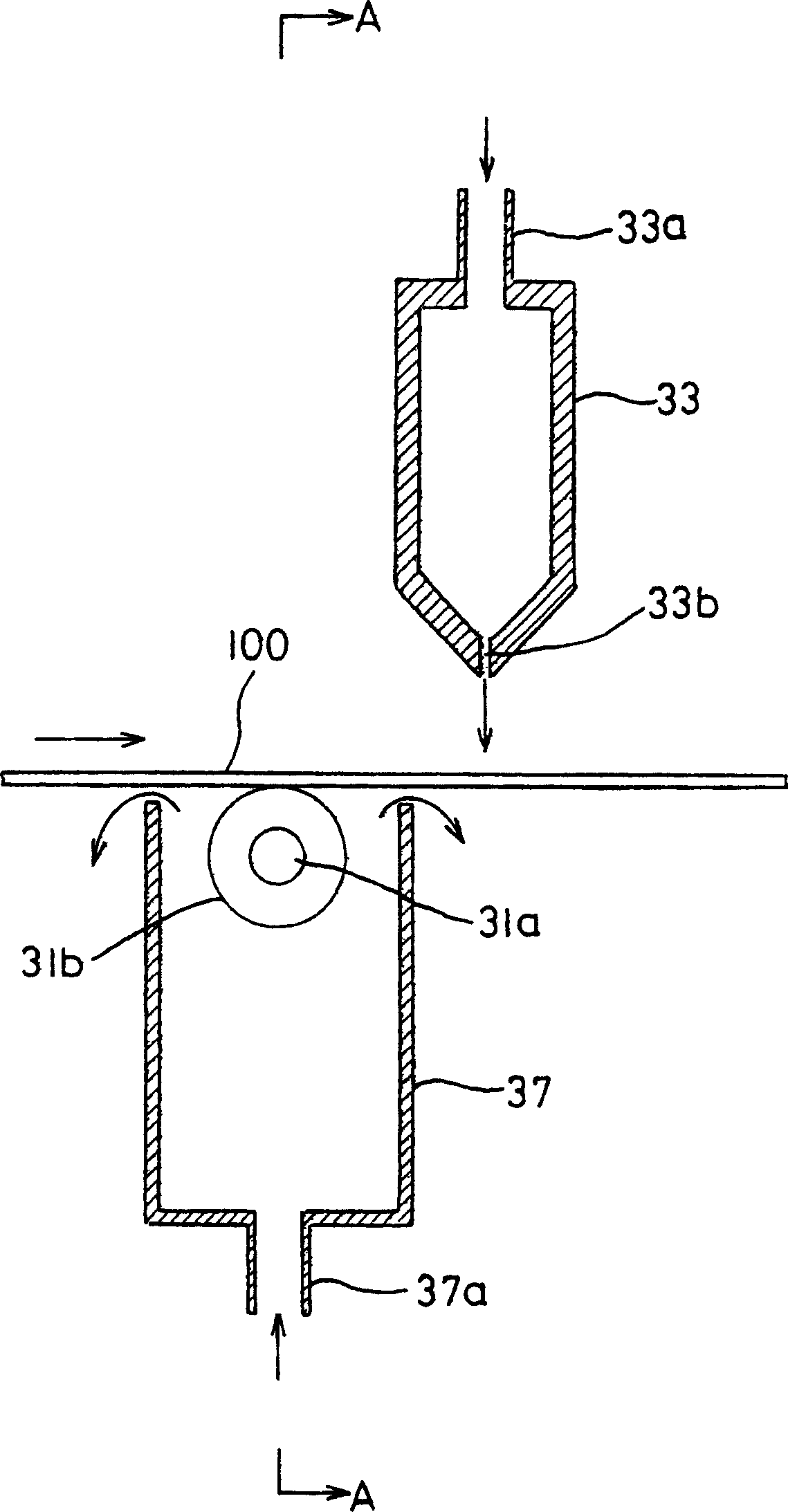

[0023] Embodiments of the present invention will be described below with reference to the drawings. figure 1 is a plan view showing a substrate processing apparatus according to an embodiment of the present invention, figure 2 is a side view of the main part of the substrate processing apparatus, image 3 It is a longitudinal sectional side view of the soaking tank and its vicinity arranged in the main part, Figure 4 is along image 3 Schematic diagram of the A-A line arrows.

[0024] The substrate processing apparatus of this embodiment is used for wet processing using a hydrofluoric acid-based etchant to form contact holes in a glass substrate 100 (hereinafter simply referred to as substrate 100 ) of a liquid crystal display device made of low-temperature polysilicon. like figure 1 As shown, the substrate processing apparatus adopts a linear first conveying line A, a second conveying line B connected at right angles to the first conveying line A, and a second conveying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com