Vortex compressor

A scroll compressor and volute technology, applied in the field of scroll compressors, can solve problems such as decline, increase in theoretical efficiency, leakage of scroll compressor compression efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

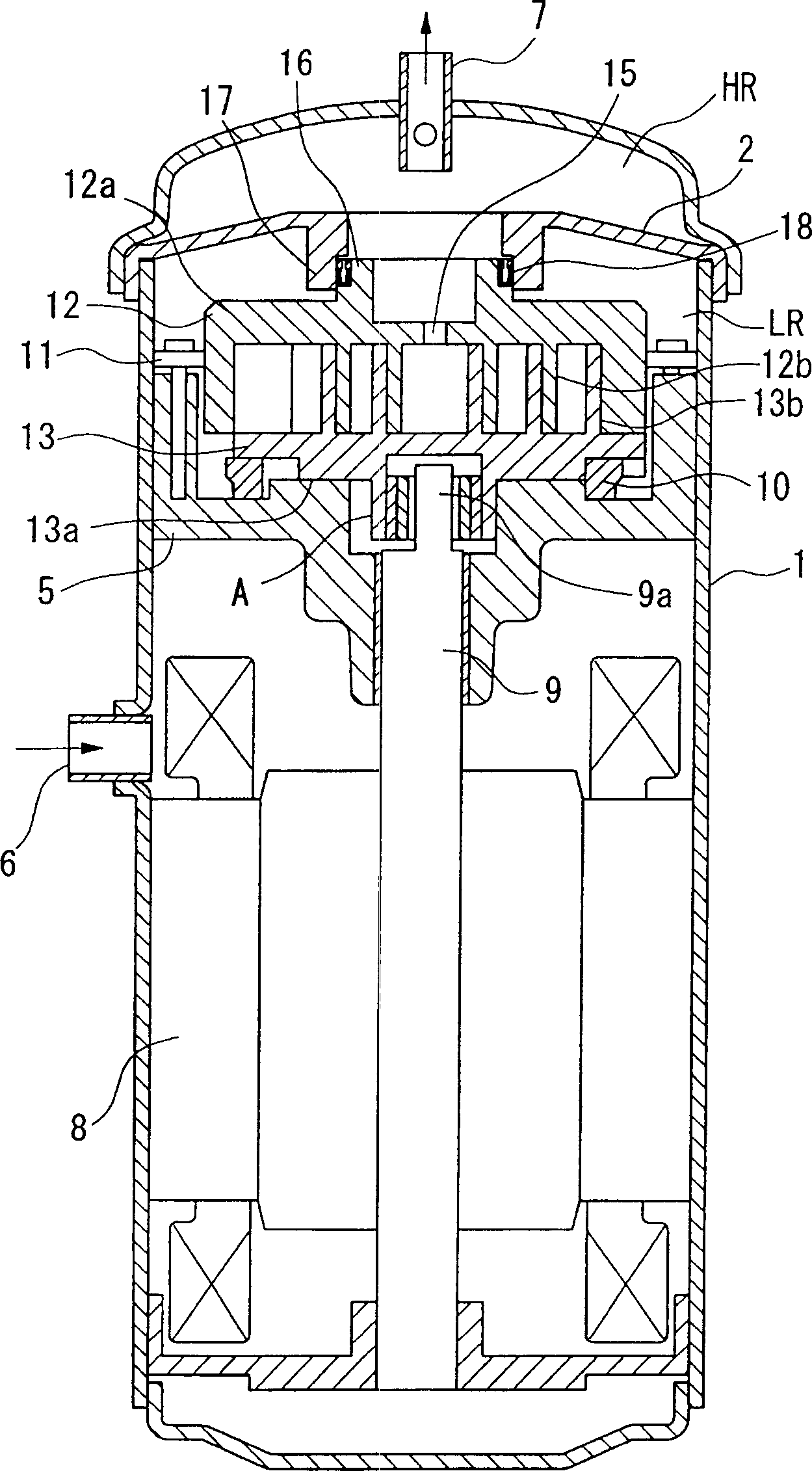

[0032] Reference attached figure 1 Up to 8, an embodiment of the scroll compressor according to the present invention will be explained.

[0033] figure 1 The structure of a back pressure scroll compressor as an embodiment of the present invention is shown. The scroll compressor includes an airtight casing 1, a discharge cover that divides the casing 1 into a high-pressure chamber (HR) and a low-pressure chamber (LR), a frame 5, a suction pipe 6, a discharge pipe 7, a motor 8, and a rotating shaft 9. And anti-rotation mechanism 10.

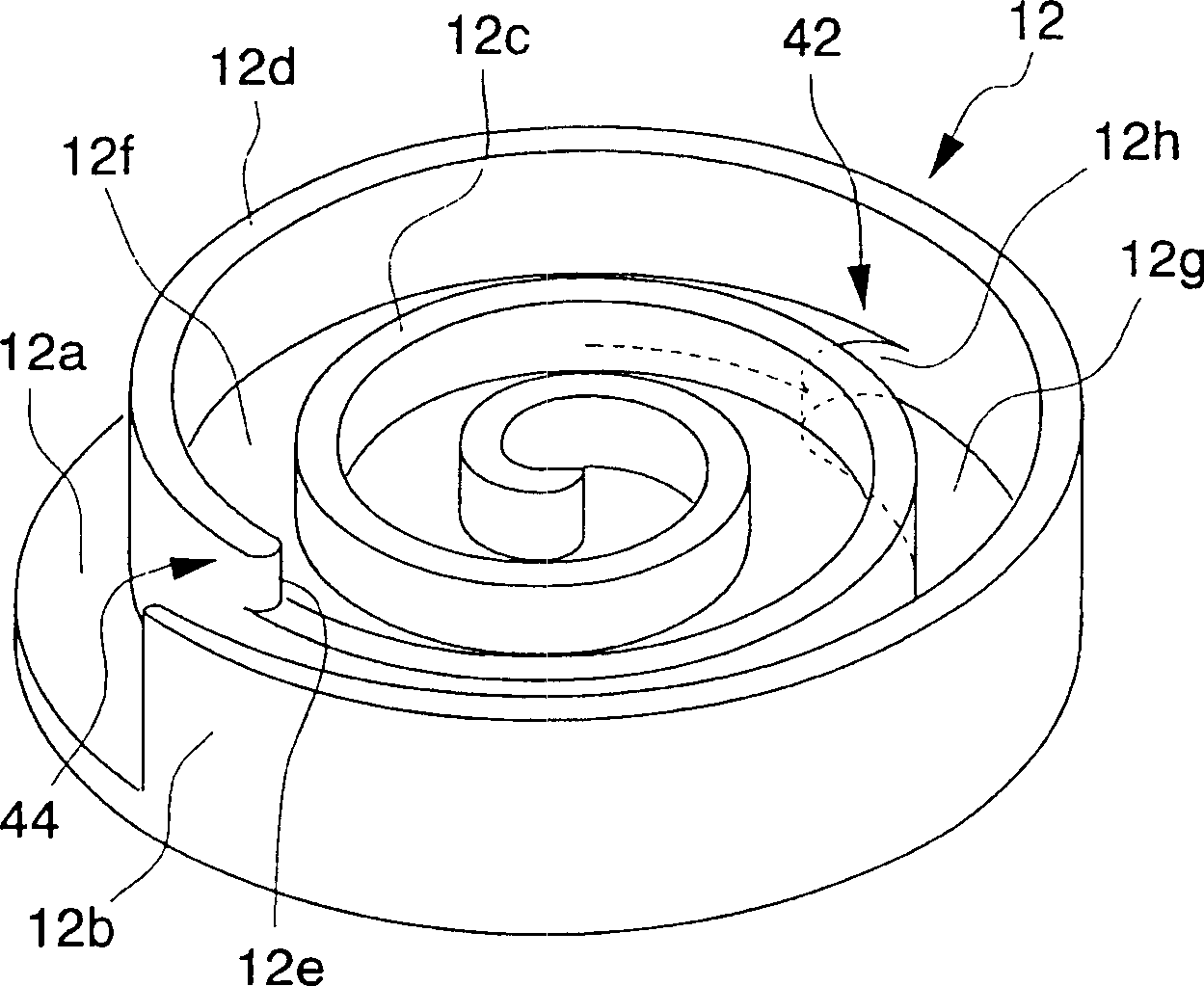

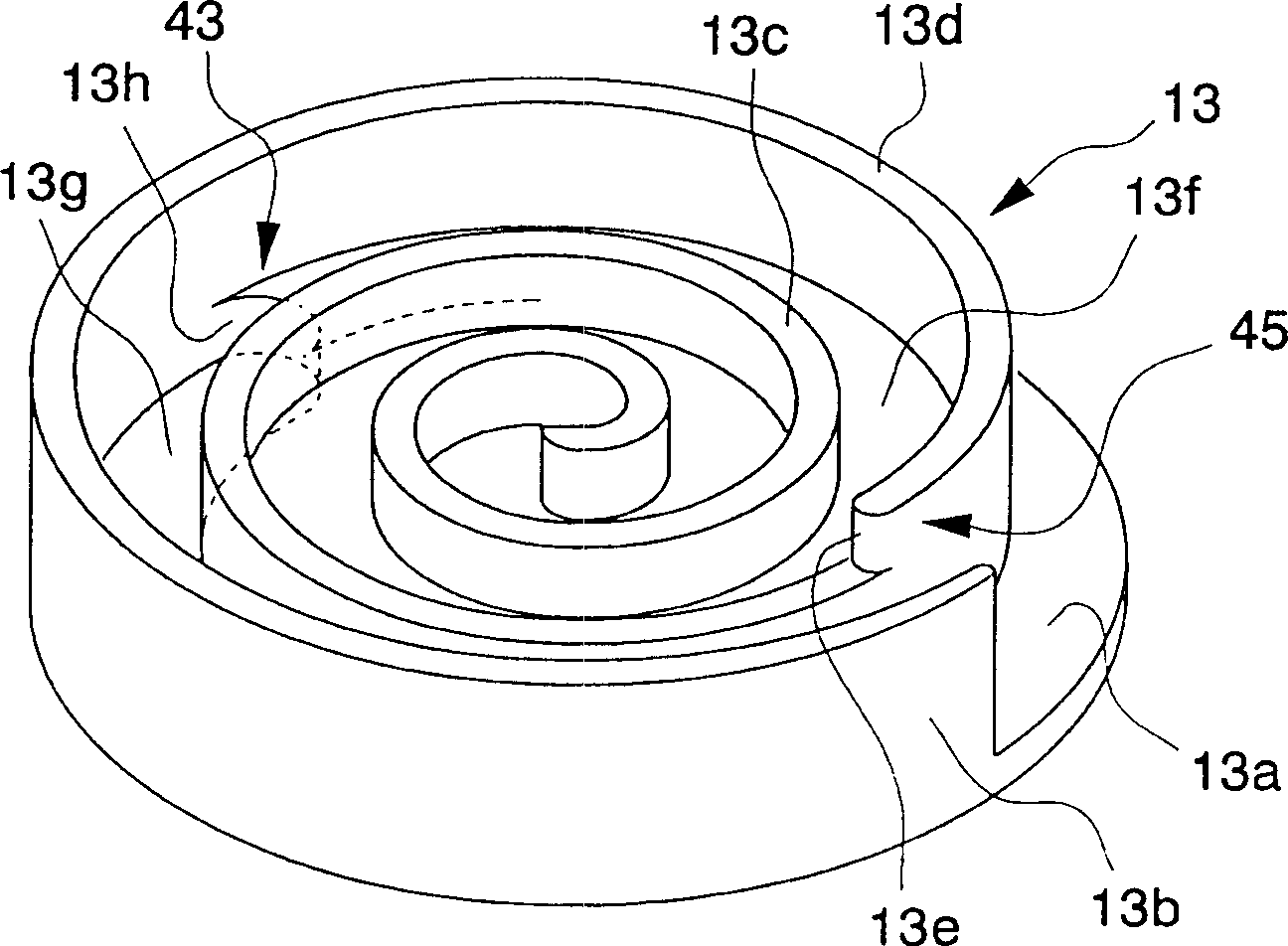

[0034] In addition, the scroll compressor has a fixed scroll 12 and an orbiting scroll 13 meshed with the fixed scroll 12. Such as figure 2 As shown, the fixed scroll 12 includes a spiral wall 12b provided on the side surface of the end plate 12a. The surrounding volute 13 also includes a spiral wall 13b arranged on the side surface of the end plate 13a. In particular, the shape of the wall 13b is similar to the wall 12b of the fixed volute 12. Th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap