Static discharge protection circuit and relative metal oxide semiconductor transistor structure

An electrostatic discharge protection, bipolar junction transistor technology, applied in semiconductor devices, semiconductor/solid-state device components, circuits, etc., can solve problems such as inability to increase, and achieve the best ESD protection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

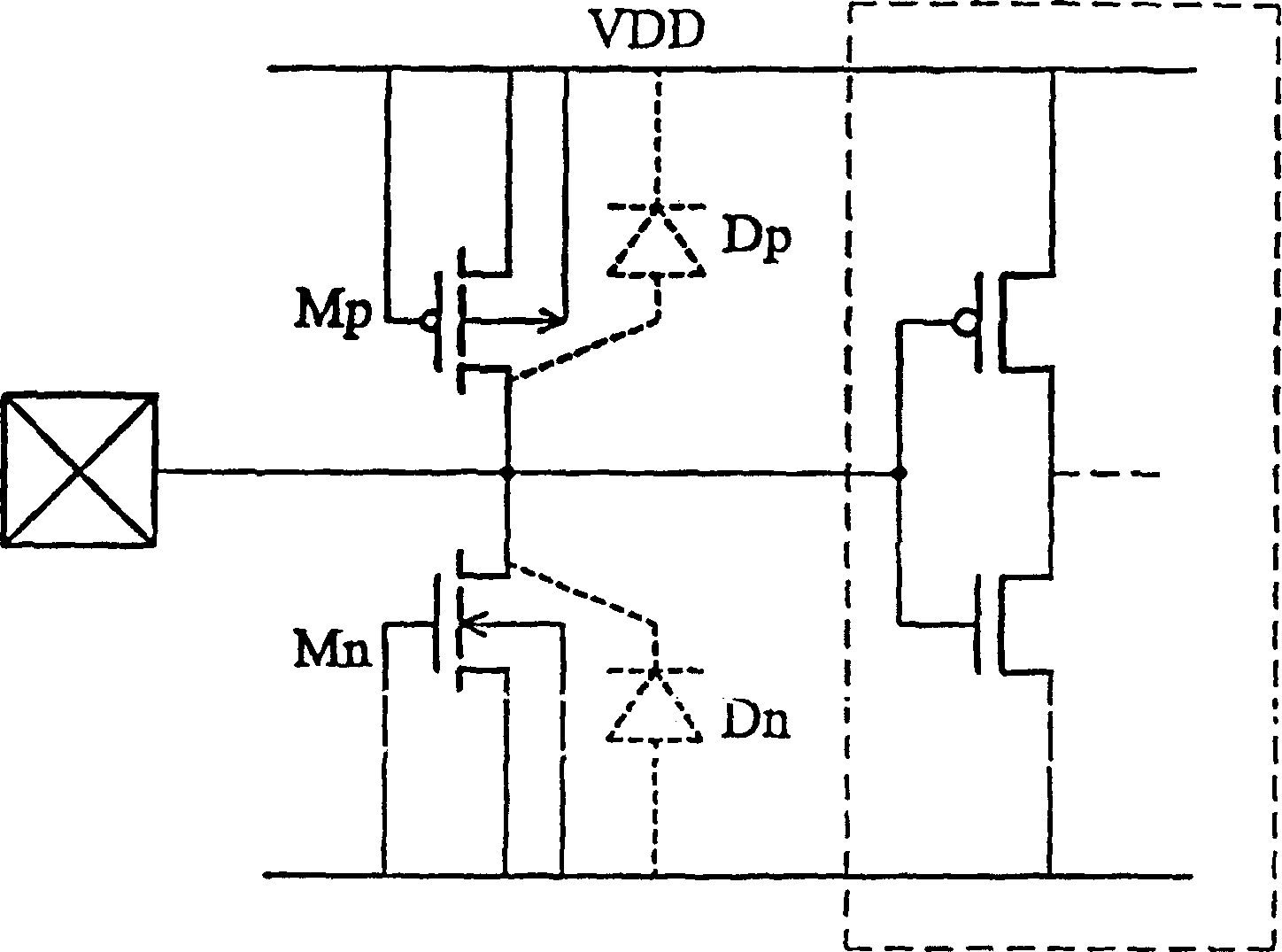

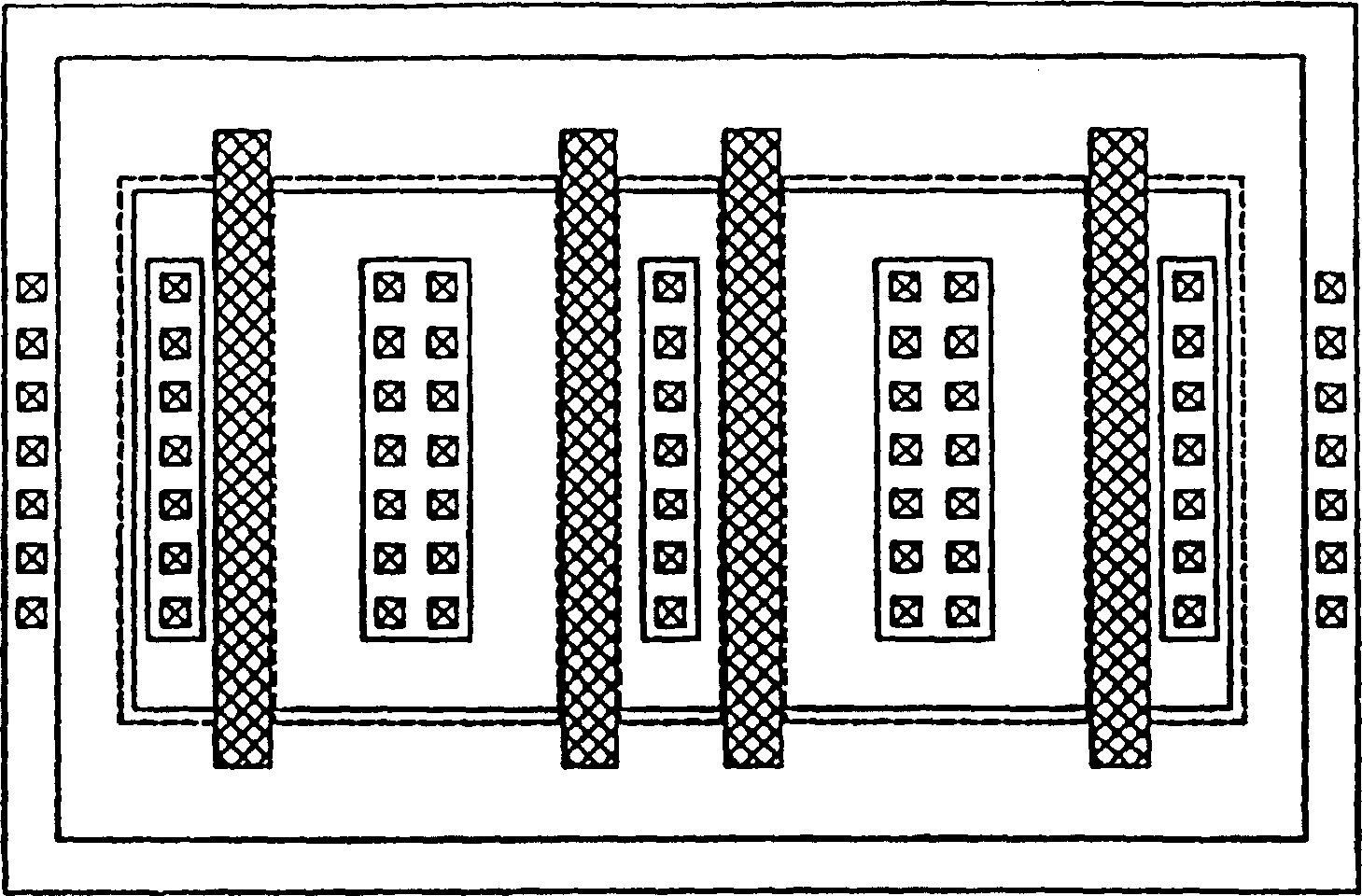

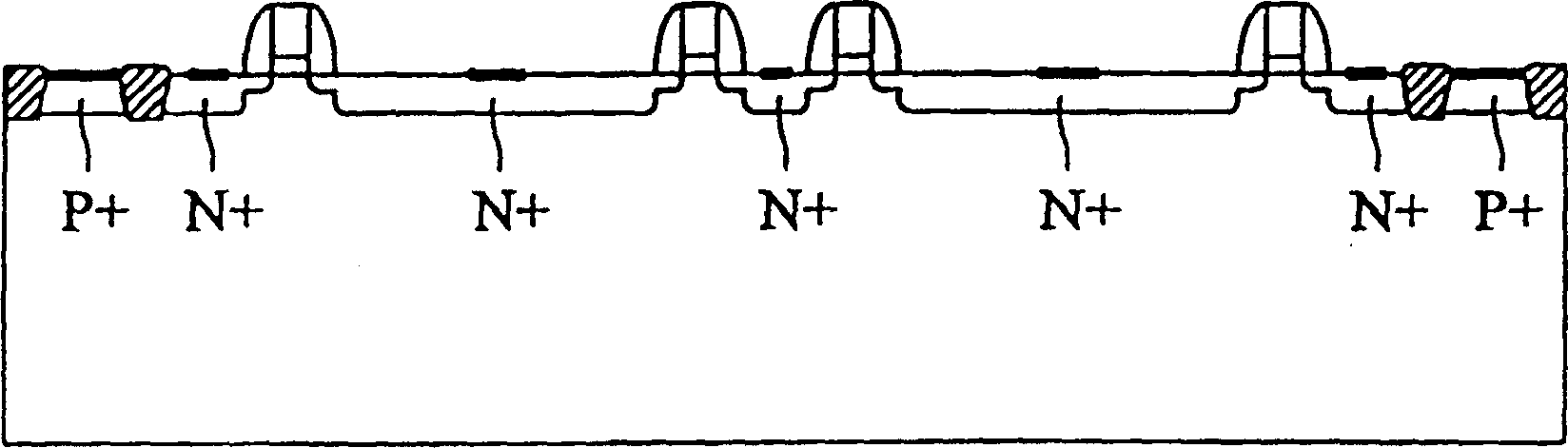

[0030] Figure 5 It is the ESD protection circuit triggered by the substrate of the present invention, which is illustrated by the concept of NMOS implementation picture . The ESD protection circuit 30 of the present invention has a multi-finger NMOS (G1-Gn finger structure), multiple transient current detection elements 32 and multiple feedback circuits 34 . A finger drain of each finger structure is coupled to a bonding pad 36 . Each transient current detection element 32 is coupled between a finger source of a finger structure and a Vss power line. The finger drain, base and finger source under each finger structure respectively constitute a collector, base and emitter of a parasitic BJT (T1-Tn). Each feedback circuit (feedback circuits) 34 is connected between the emitter of one parasitic BJT and the base of another parasitic BJT, such as Figure 5 shown.

[0031] The main principle of the present invention is as follows. If the multi-finger NMOS is not evenly trigg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com