Sample component analysis system and sensor chip and sensor pack used for the system

A sensor chip and component analysis technology, which is applied in the direction of analyzing materials, using chemical indicators to analyze, and analyzing materials through optical means, can solve problems such as failure, overall size increase, and cost increase.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

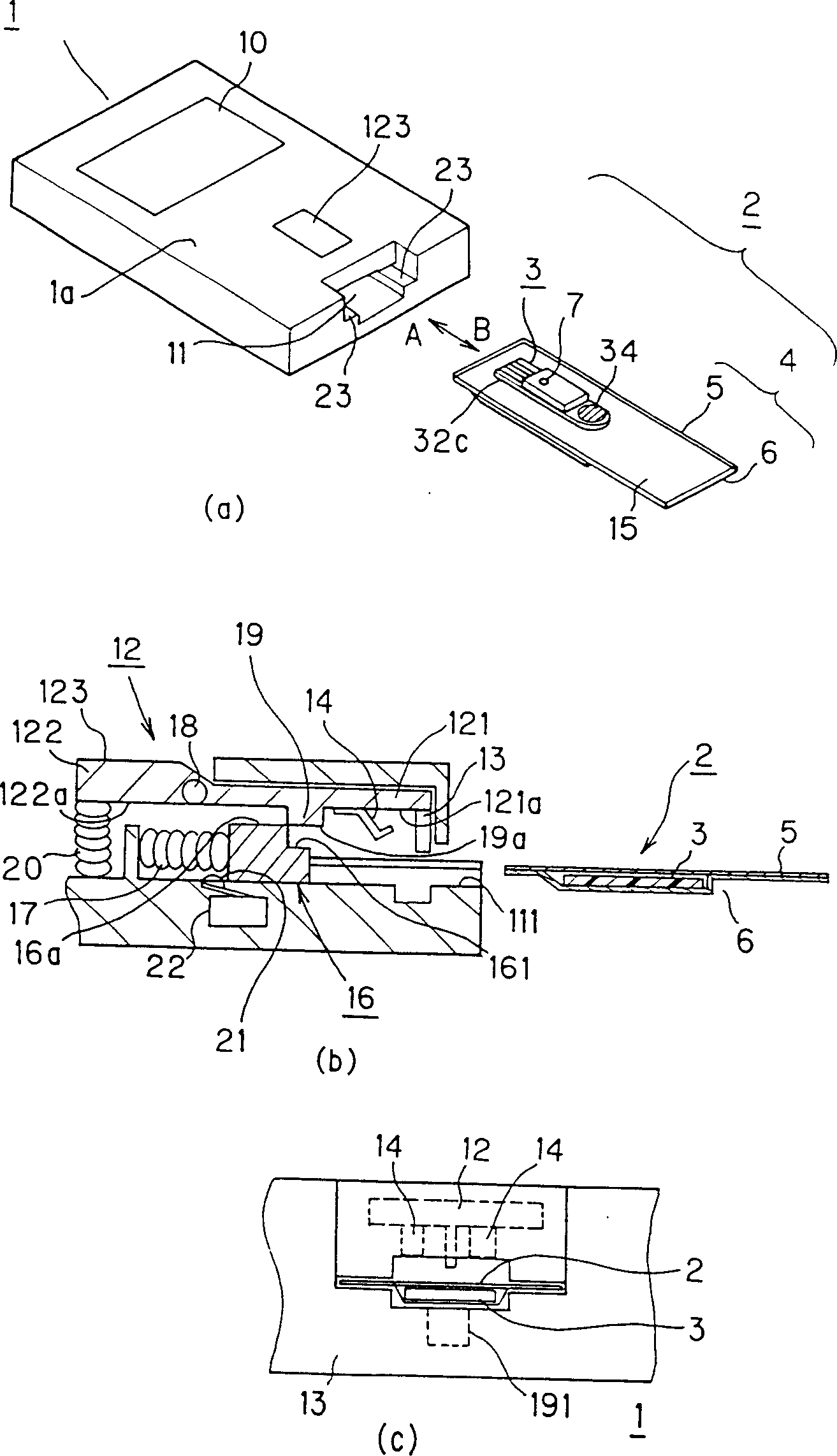

[0138] Figure 4 An analytical instrument 41 and a sensor pack 2 of the second embodiment of the present invention are shown.

[0139] The same components or parts as those in the first embodiment are denoted by the same reference numerals, and descriptions thereof are omitted.

[0140] The structures of the sensor pack 2 and the sensor chip 3 in this embodiment are the same as those in the first embodiment.

[0141] The structures of the fixing member 13 and the connection electrode 14 of the analytical instrument 41 are the same as those of the first embodiment. In this embodiment, however, one support 42 can be opened and closed by moving relative to the body of the analytical instrument 41 .

[0142] The supporting member 42 is connected to the main body of the analyzing instrument 41 by a hinge or the like so as to be swingable along a plane perpendicular to the insertion direction of the sensor pack 2 . As in the first embodiment, a pair of guide portions 23, 23 are f...

no. 3 example

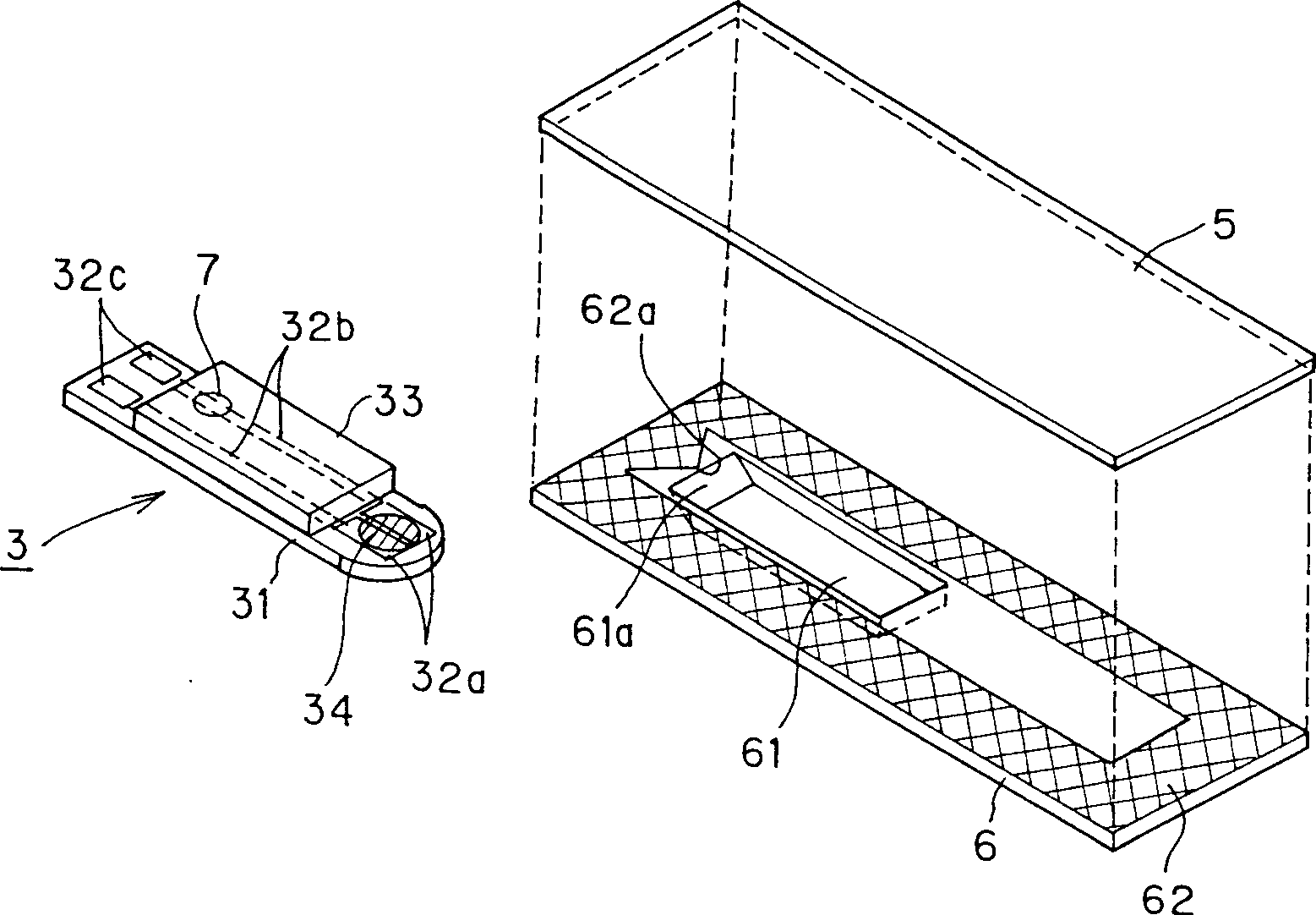

[0149] Figure 5 (a) to 5(d) show an analyzing instrument 51 and a sensor pack 52 of the third embodiment of the present invention.

[0150] The same components or portions in this embodiment as those in the first embodiment are denoted by the same reference numerals, and descriptions thereof are omitted.

[0151] In this embodiment, one groove 53 is formed in one side of the analyzer 51 , and the sensor pack 52 is inserted into the groove 53 in the direction of the arrow and the sensor chip 3 is disposed through the groove 53 .

[0152] Figure 5 (a) shows the overall structure of the analyzer 51 and the sensor pack 52 . Figure 5 (b) is a top view of the analytical instrument 51, Figure 5 (c) is from Figure 5 (b) is a side view looking from the underside, while Figure 5 (d) is from Figure 5 A side view when looking from the right side of (b). These views only show the basic parts and the external structure of the analytical instrument 51, and do not show other com...

no. 5 example

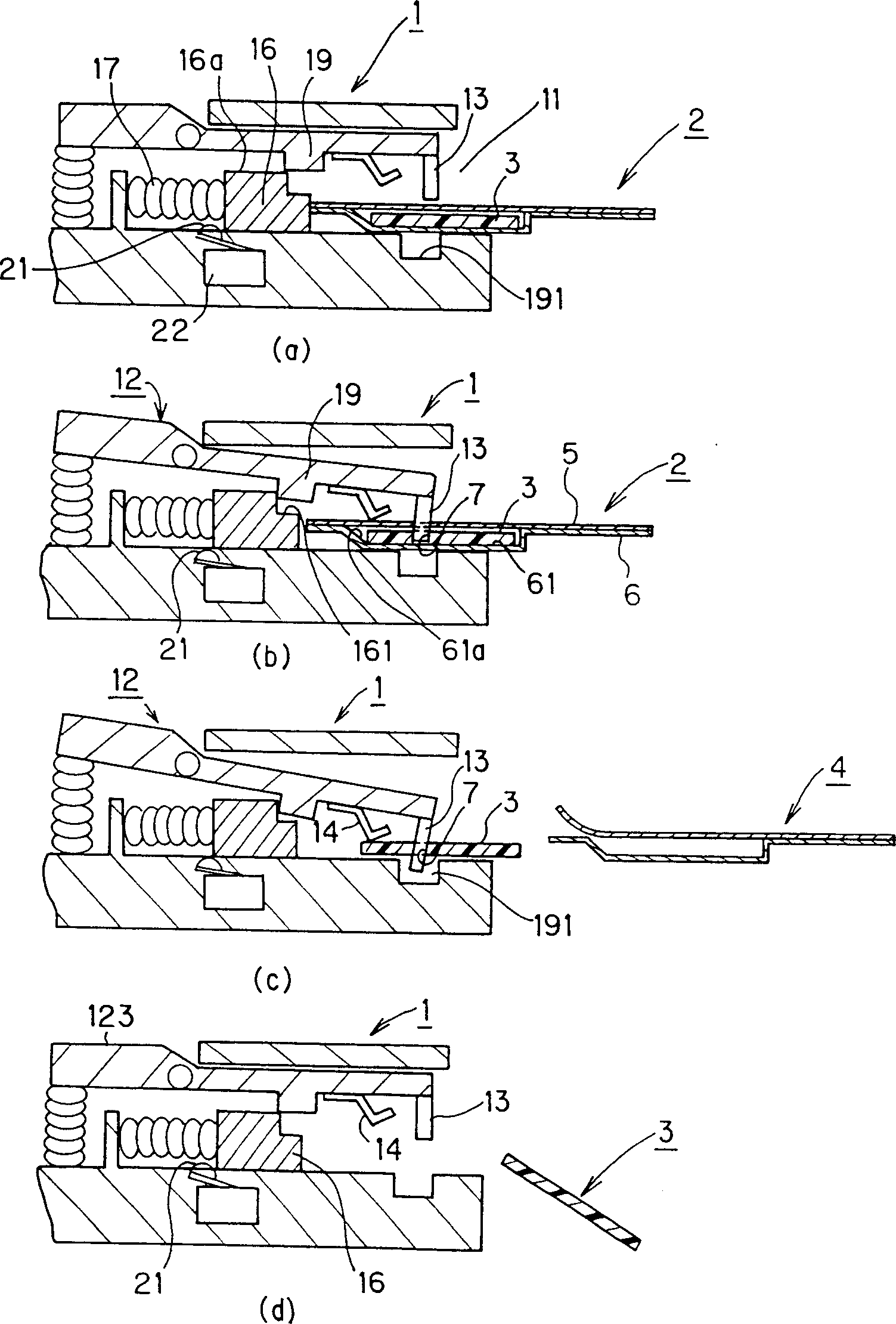

[0171] Figure 7 An analytical instrument 1 and a sensor pack 70 of a fifth embodiment of the present invention are shown.

[0172] The same components or parts as those in the first embodiment are denoted by the same reference numerals, and descriptions thereof are omitted.

[0173] In this embodiment, the sensor package 70 has the same sensor chip housing structure as in the first embodiment. In the sensor pack 70, ends of a plurality of sensor chip housing parts 72 opposite to the insertion side are connected by a connection part 71, and the sensor chip 3 is housed in each housing extending from the connection part 71 like comb teeth. Section 72. The analytical instrument 1 also has basically the same structure as that of the first embodiment. However, in this embodiment, the analytical instrument 1 differs from the first embodiment in that the sides where the opening 11 is formed are cut away in the horizontal direction at their ends opposite to each other in order to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com