Combine harvester heat-sinking and cooling device

A technology of combine harvester and cooling device, applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of poor maintainability, decreased wind speed, adhesion of dust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

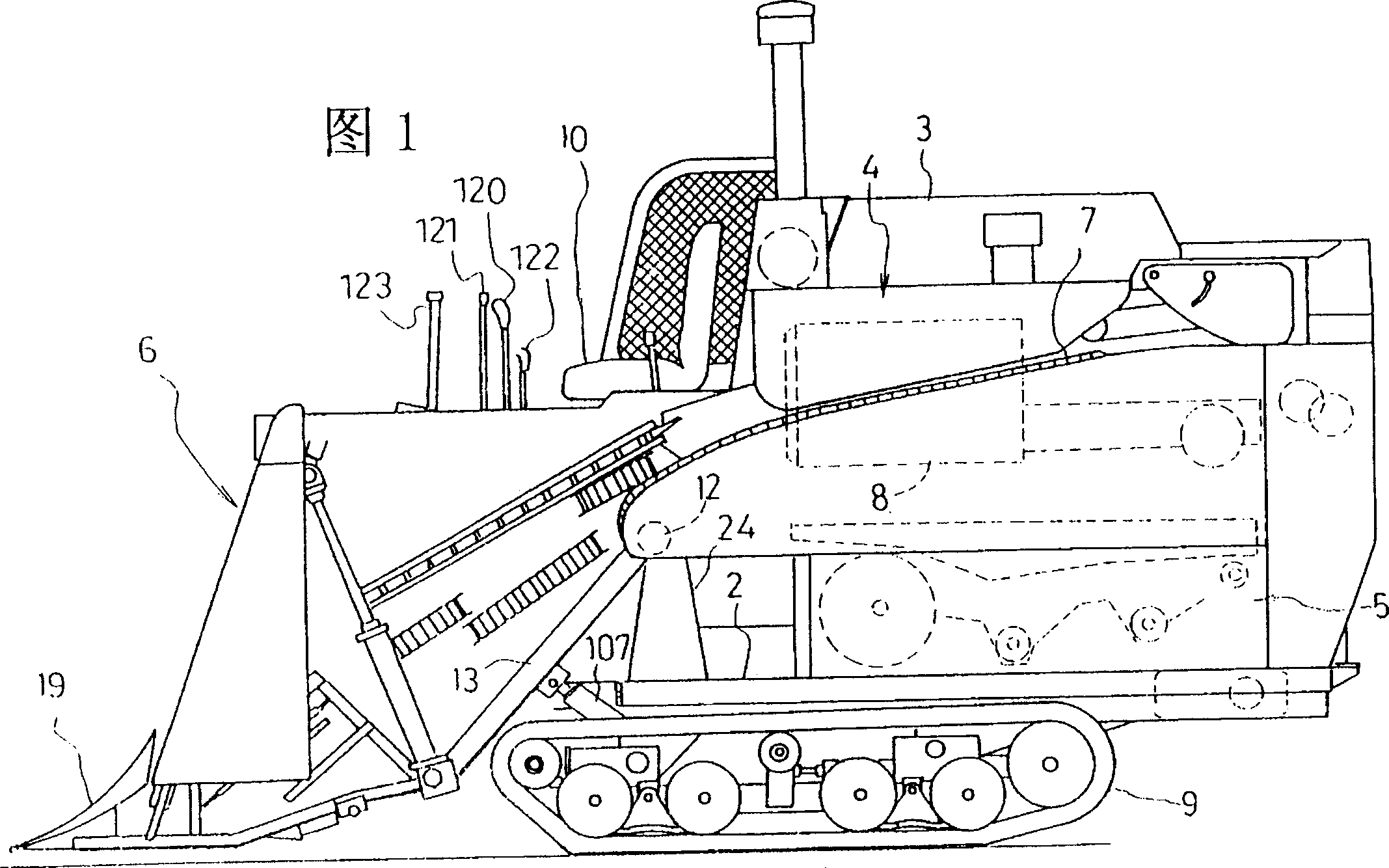

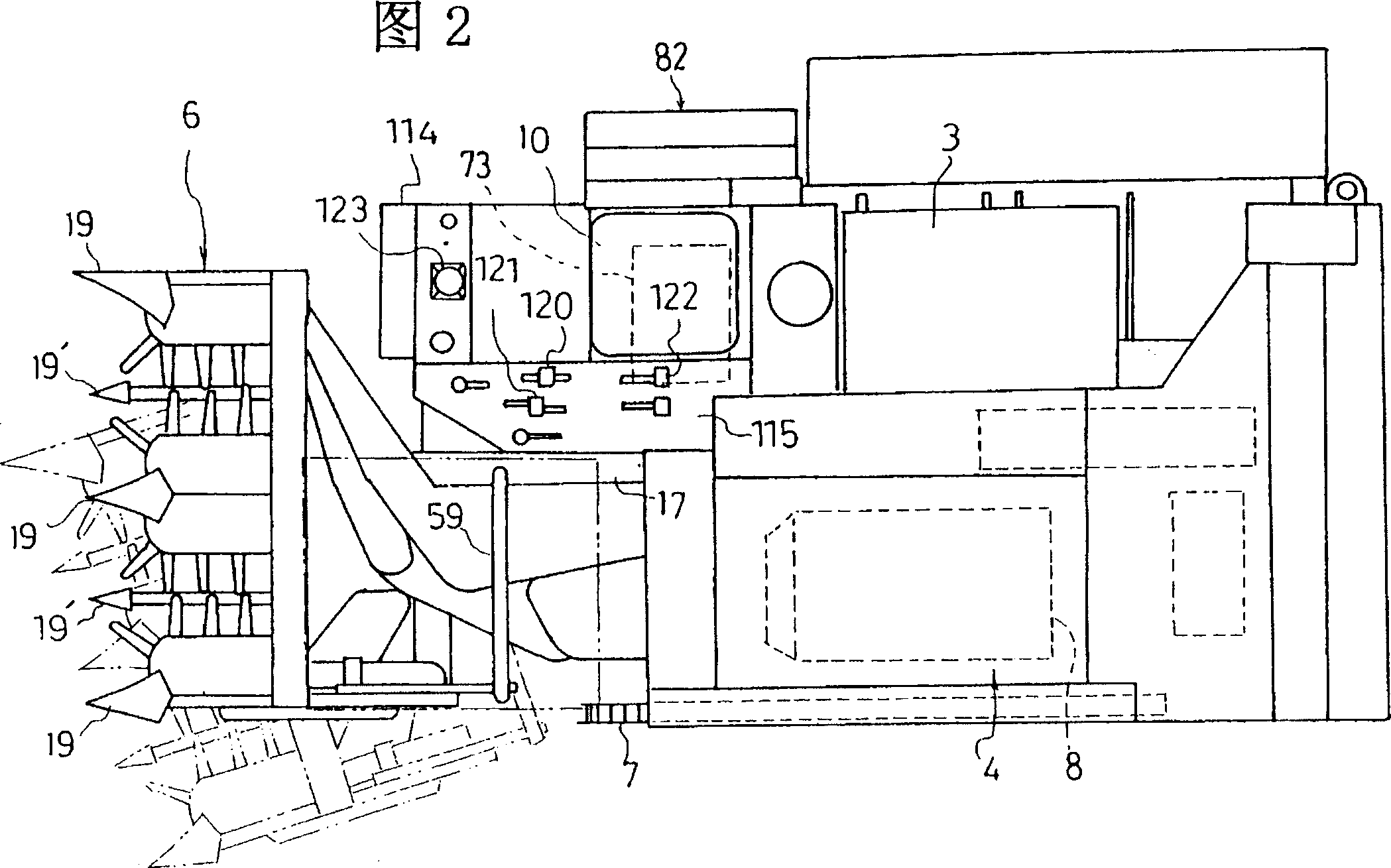

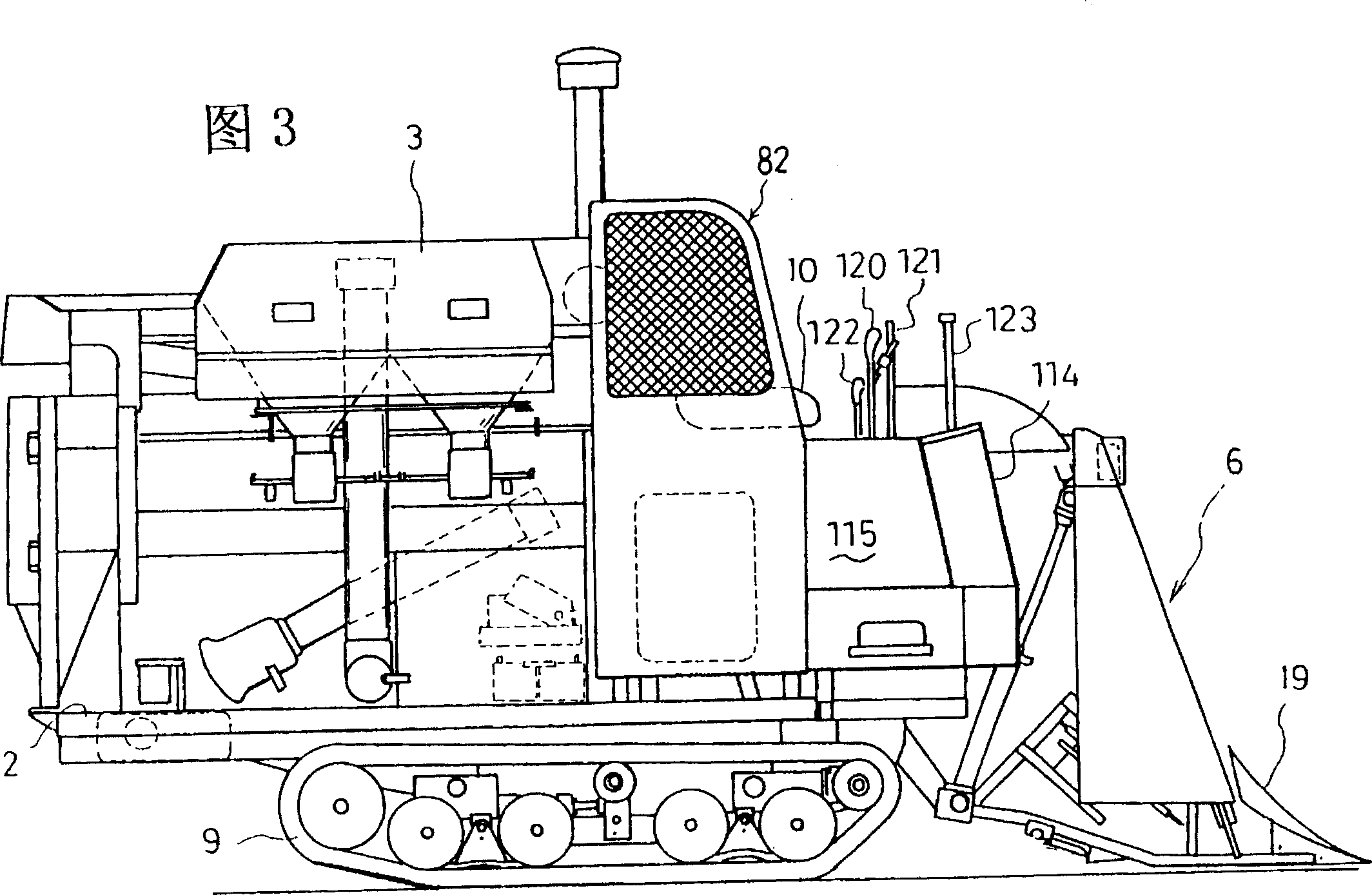

[0014] First, the overall configuration of the combine will be described.

[0015] As shown in Figures 1-3, a frame 2 is installed on the crawler-type traveling device 9, on which, the threshing section 4 and the sorting section 5 are placed on the left side of the body in the direction of travel, and the driver's seat is placed on the right side. 10 and the upper case 3 of storing grain.

[0016] The harvesting unit 6 is located at the forefront of the machine body in front of the threshing unit 4, and each conveying device of the harvesting unit 6 transports the harvested rice straw to the supply chain 7 on the side of the threshing unit 4, and the rice straw transported by the supply chain 7 After being threshed by the threshing drum 8, it is sent to the upper box 3 from the above-mentioned sorting part 5.

[0017] In the frame 2 front portion of above-mentioned driver's seat 10 side, form the mounting table 24 that can support cutting part 6 along up and down rotation, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com