Motor-driven adjustable supporting device for upholstery of sitting and/or reclining furniture, for example of mattress or of bed

A technology of a supporting device and a driving device, which is applied to household appliances, other seating furniture, applications, etc., can solve the problems of high axial motor structure and manufacturing cost, and achieve the effects of economical structure, strong structure and simplified structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

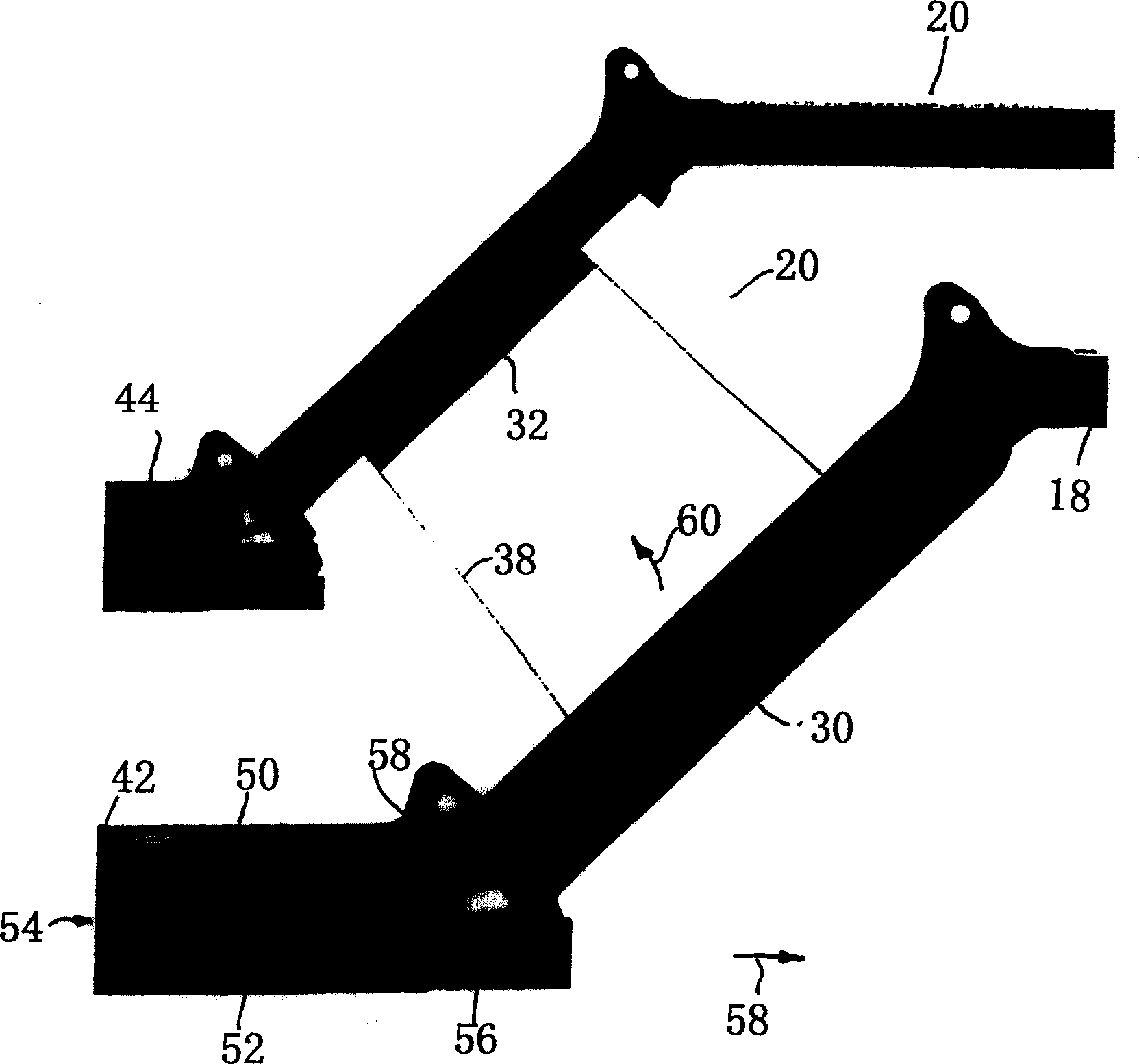

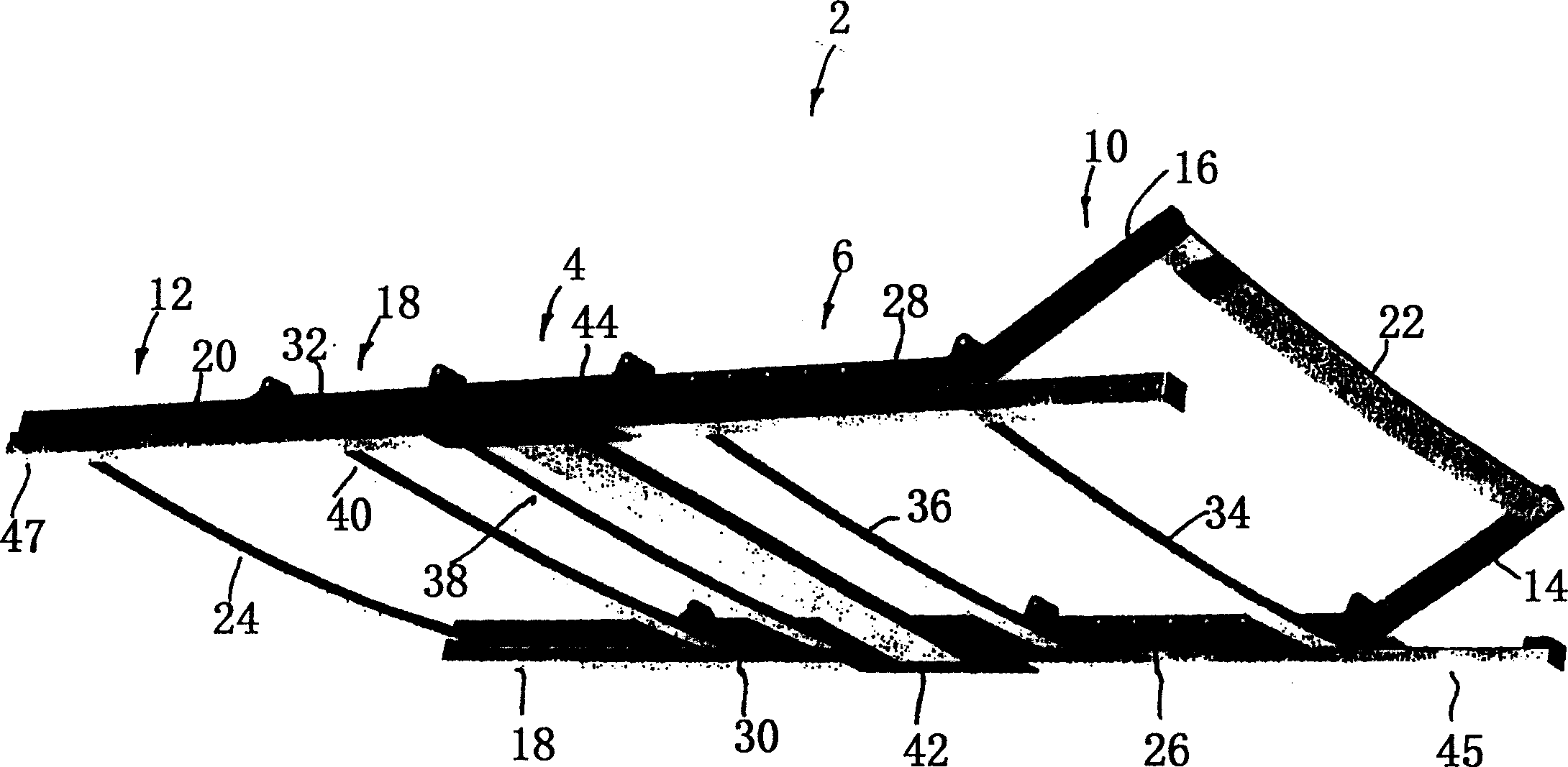

[0040] In the drawings, the same or corresponding structural members are given the same reference numerals.

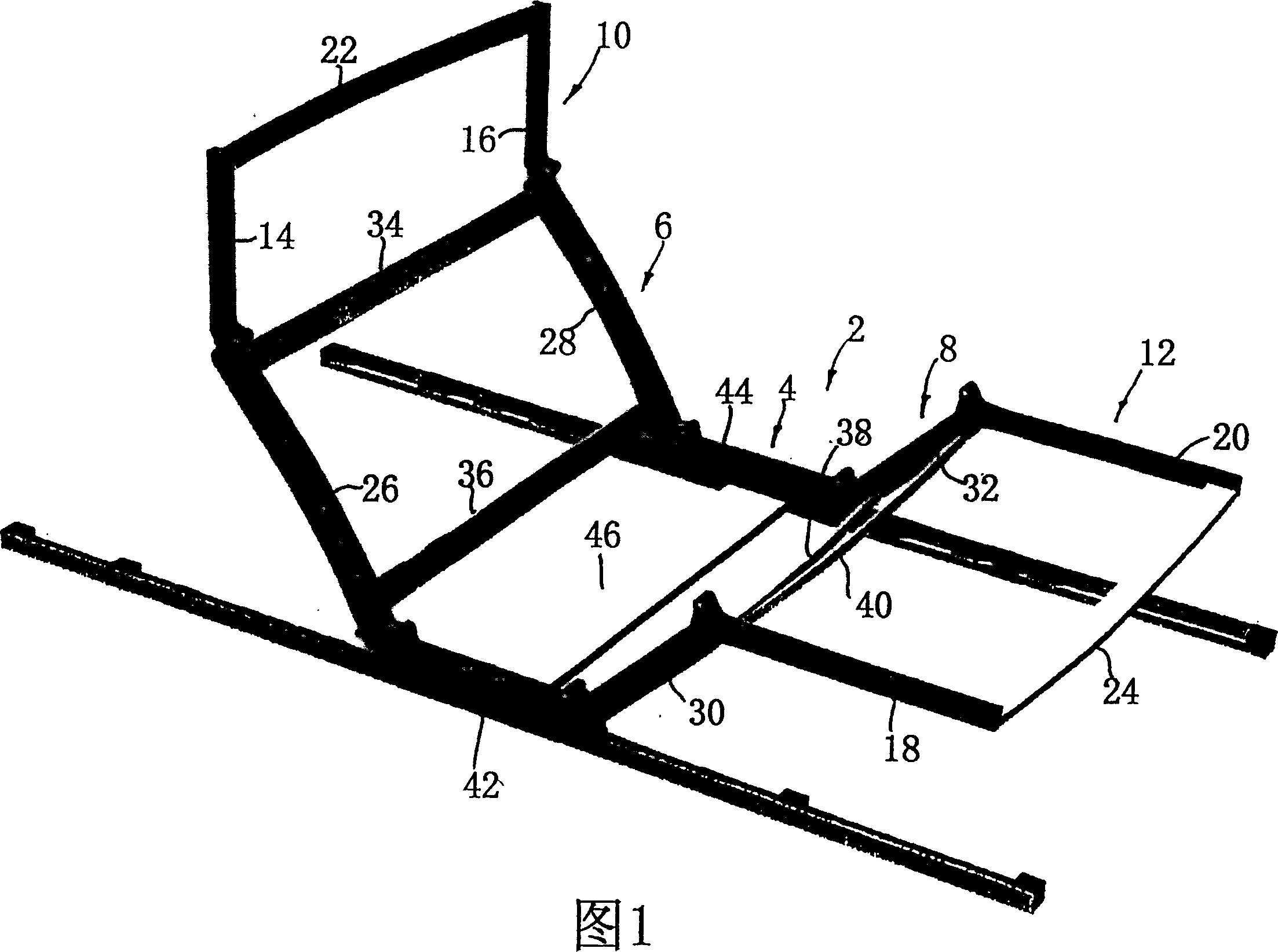

[0041]FIG. 1 shows a slat grate 2 , which along its longitudinal direction is successively connected with supports 4 , 6 , 8 , 10 , 12 for surface support of a mattress not shown in the figure.

[0042] In detail, the slat grate 2 has a first support, which forms an intermediate support 4, an upper body support 6 hinged on one side of the intermediate support, and can swing around a horizontal swing axis, and a leg support Part 8 is hinged with the middle support member at its side away from upper body support member 6, and can swing around a horizontal swing axis.

[0043] A head support 10 and the upper body support 6 are hinged on the side away from the middle support 4, and can swing around a horizontal swing axis, and the calf support 12 and the leg support 8 leave the middle support at it. One side of 4 is hinged, and can swing around a horizontal swing axis.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com