Continuous scanning synchronous control method and system for step scanning photoetching machine

A scanning synchronization, step-scanning technology, applied in microlithography exposure equipment, semiconductor/solid-state device manufacturing, photolithography process exposure devices, etc., to achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] For a better understanding of the present invention, using the negotiation mechanism, queuing mechanism and synchronous control system structure proposed by the present invention, we propose a specific embodiment to realize the continuous exposure and scanning synchronous control of the step-and-scan projection lithography machine. The scope of protection is not limited to the scope determined in this embodiment.

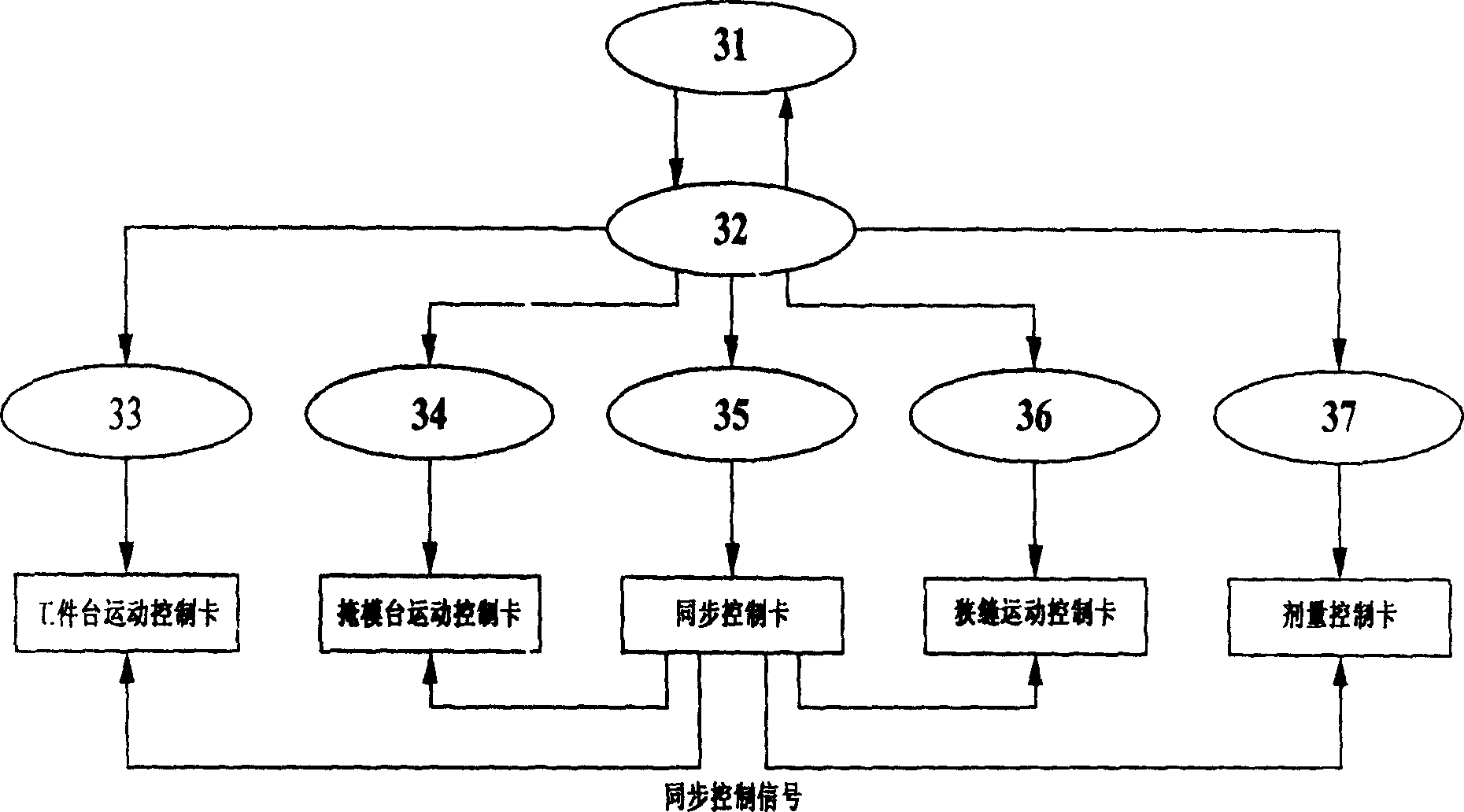

[0048] Such as Figure 5 As shown, as a preferred embodiment, the control system is composed of a host computer 100 and several subsystem control units. The upper computer 100 adopts a workstation or an industrial control PC, using operating systems such as Unix or Windwos; the main control CPU board of the sub-system control unit, such as a real-time operating system such as WinCE; the upper computer 100 and the sub-system control unit through industrial Ethernet, industrial Communication methods such as fieldbus are interconnected. Between the internal bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com