Event-driven synchronous control method for jet ignition of EFI si engine

A synchronous control, event-driven technology, applied in the direction of engine control, electric engine control automatic control, electrical control, etc., to ensure integrity, achieve precise synchronization control, and achieve the effect of distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way, and any transformation made based on the teaching of the present invention falls within the protection scope of the present invention.

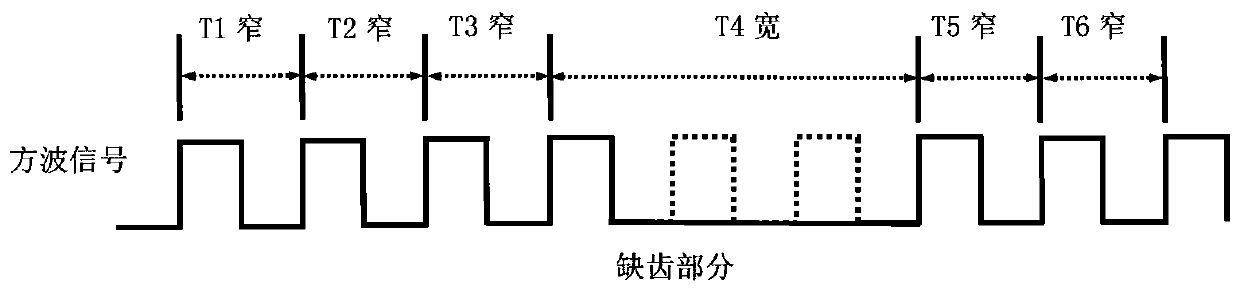

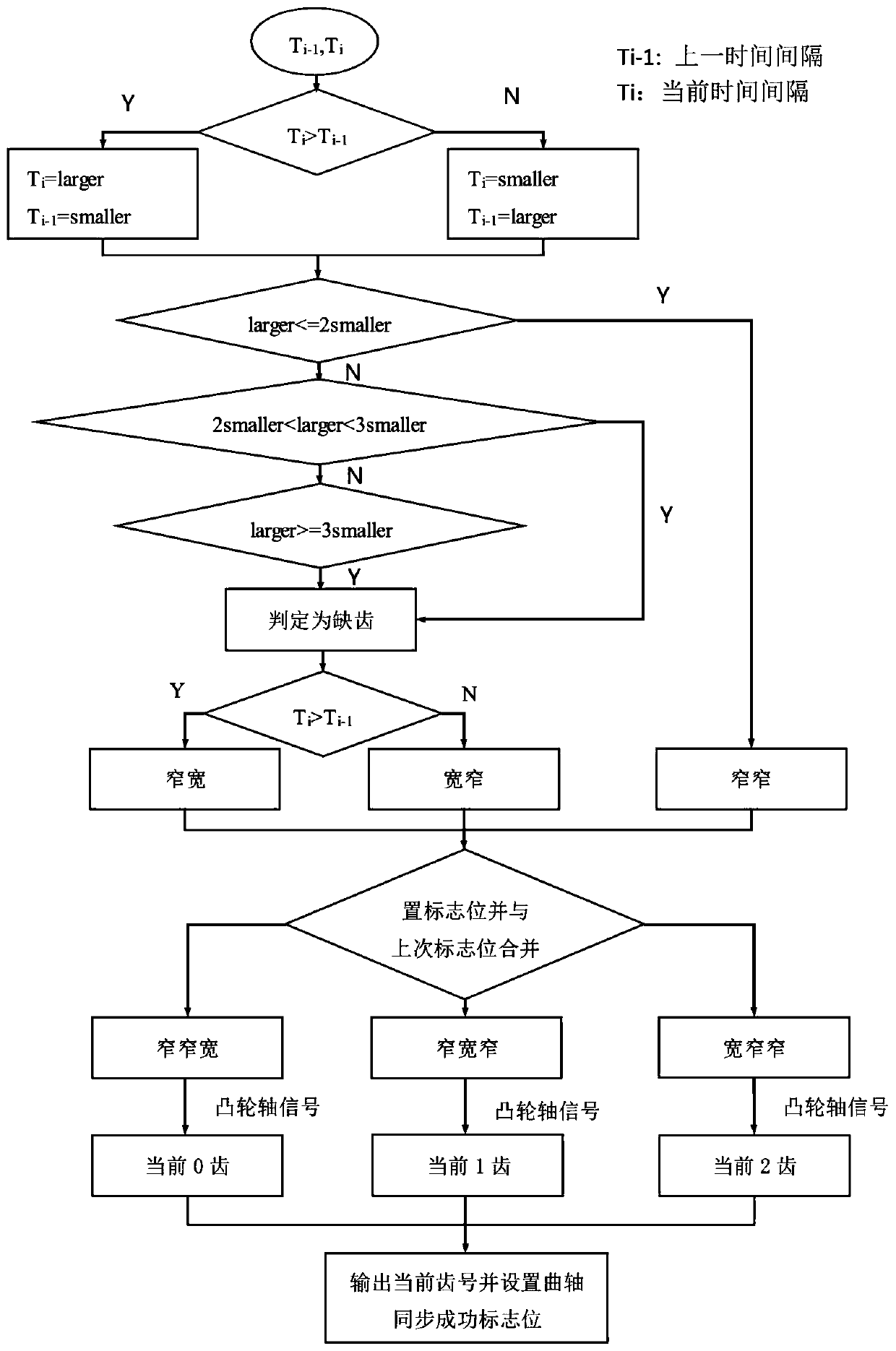

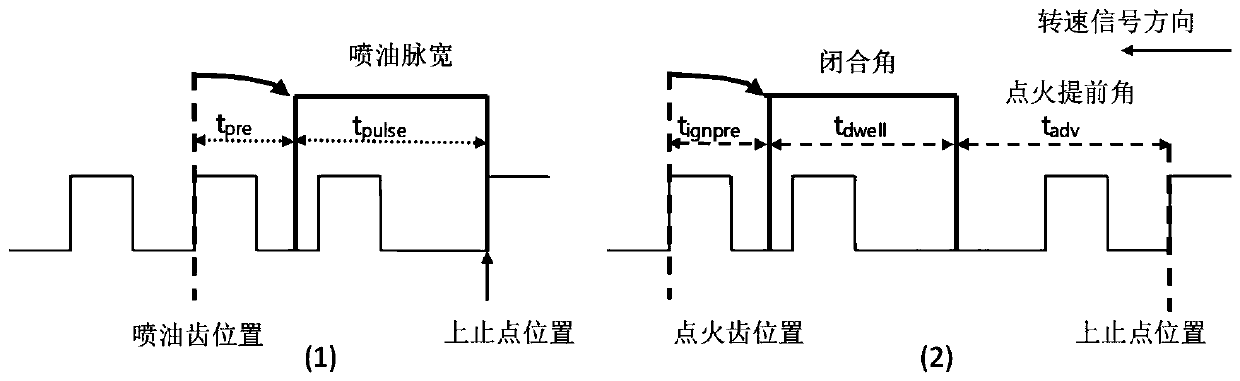

[0050] The crankshaft position signal is the basis of the jet ignition timing. Generally, the signal is obtained through a non-contact sensor installed on the engine body. The engine management system usually uses a magnetoelectric sensor equipped with a permanent magnet and an iron sensor installed on the crankshaft. The pulse disc made of magnetic material is used to judge the current position and speed of the crankshaft. The pulse disc of this type of engine is evenly distributed by 60 teeth, two of which are vacant. When the pulse disc rotates with the crankshaft, the permanent magnetic force lines in the cutting sensors of each tooth will cause the magnetic flux to change and gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com