Automatic assembly system

A technology of automatic assembly and robotics, which is applied in the direction of assembly machines, manipulators, metal processing equipment, etc., can solve the problems of poor flexibility and high cost, and achieve the effect of low cost, reasonable system design and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

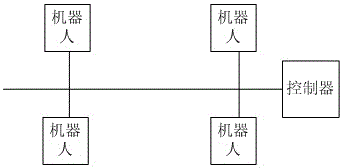

[0020] In the first embodiment, an automatic assembly system is provided, please refer to figure 1 , the system includes: 4 robots, all the robots are interconnected through the network, and can be connected to the main controller of the unit through the bus, so as to realize the precise synchronous control of the robots, and the 4 robots are used to cooperate to realize automatic assembly.

[0021] Among them, in the embodiment of the present application, the robot detects the position of the workpiece through the laser scanner on the end effector during the initialization process, and obtains the relative position between the workpiece and the robot. When the workpiece is detected and found, the control command will be sent to to the program database, and then the robot will complete the preset operation according to the stored program sequence.

[0022] Wherein, in the embodiment of the present application, the robot re-scans the workpiece before performing each operation,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com