Hydraulic loop system for controlling roll gap of all-hydraulic flattening machine

A hydraulic circuit, straightening machine technology, applied in the direction of mechanical equipment, etc., can solve the problems of complex control equipment, low control accuracy, high failure rate, etc., to achieve the effect of improving system stiffness, improving responsiveness, and reducing accident rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

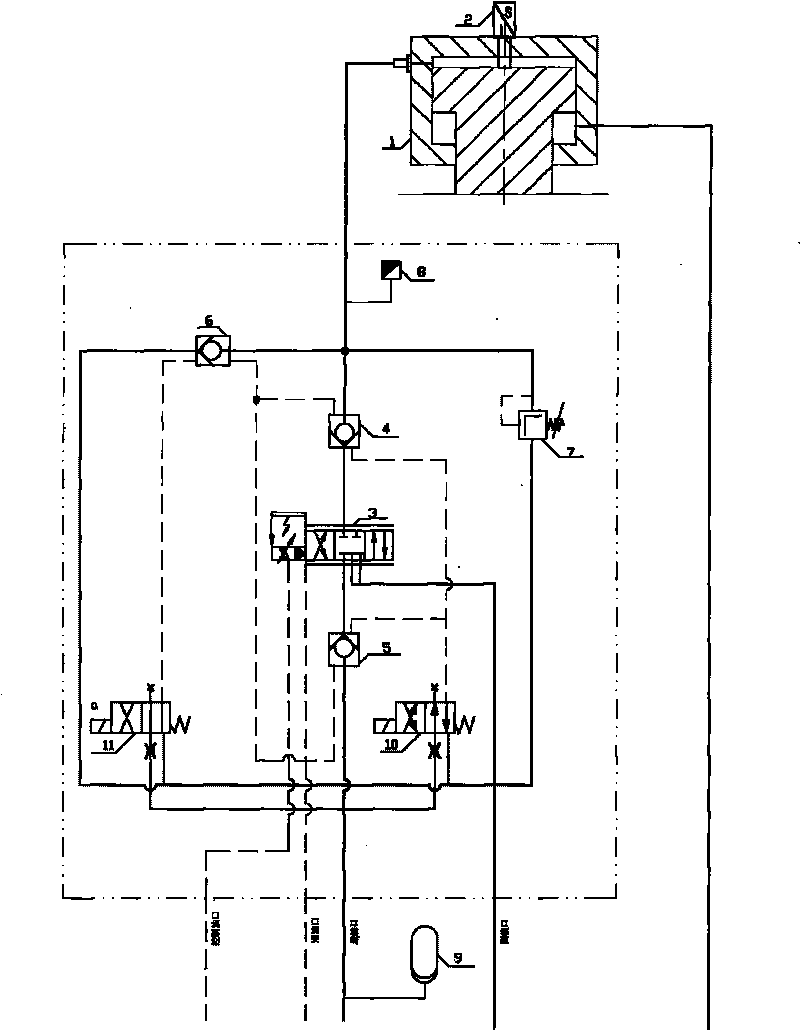

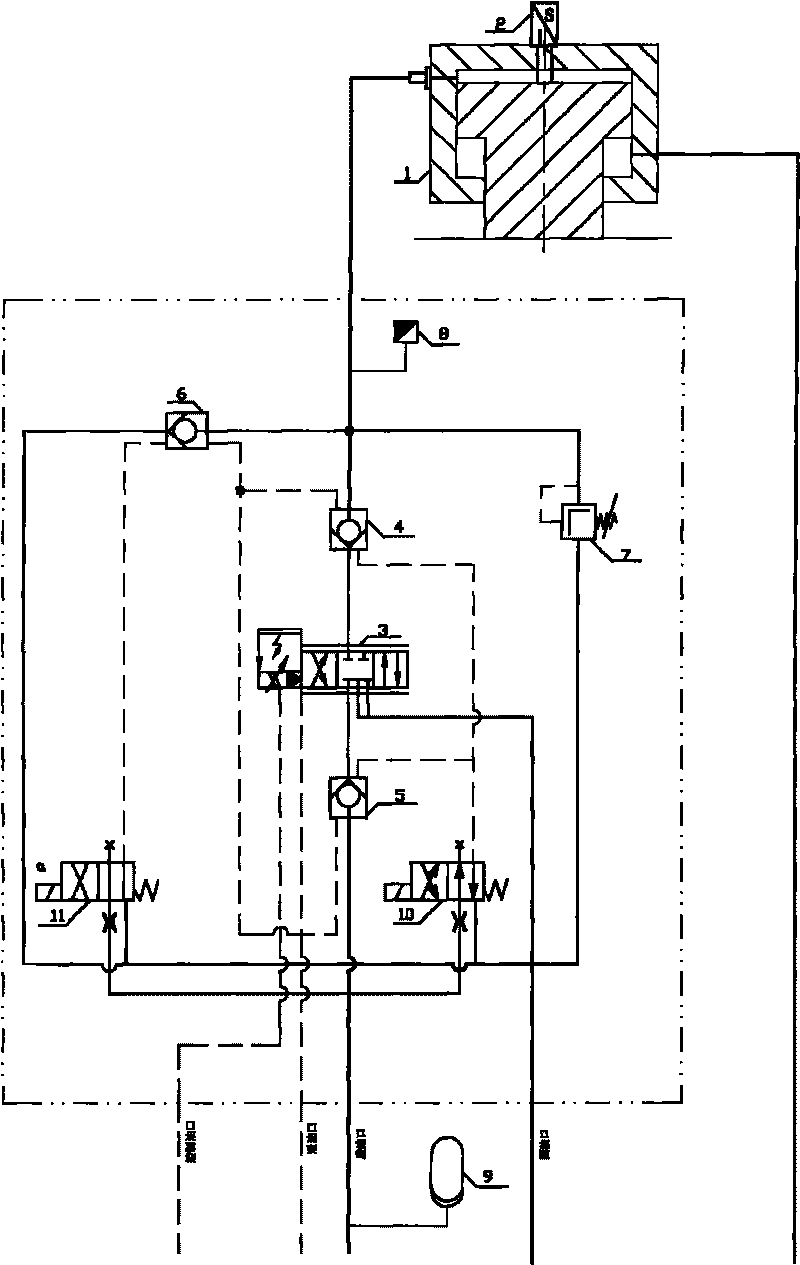

[0018] Such as figure 1 A hydraulic circuit system for roll gap control of a fully hydraulic leveler in a medium and thick plate hot rolling production line is shown, consisting of four sets of hydraulic circuits. Each set of roll gap control hydraulic circuit is composed of the following components: roll gap control hydraulic cylinder, displacement sensor placed on the upper part of the hydraulic cylinder, hydraulic control valve block, and bladder accumulator. Each set of hydraulic control valve block is composed of two plate-type two-position four-way electromagnetic reversing valves, one plate-type servo valve, three plate-type hydraulic control check valves, one cartridge relief valve and one pressure sensor integrated in one valve block superior. The integrated valve block is located directly above the roll gap control hydraulic cylinder, and is fixed on the straightener frame by bolts. The integrated valve group block is connected with the roll gap control hydraulic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com