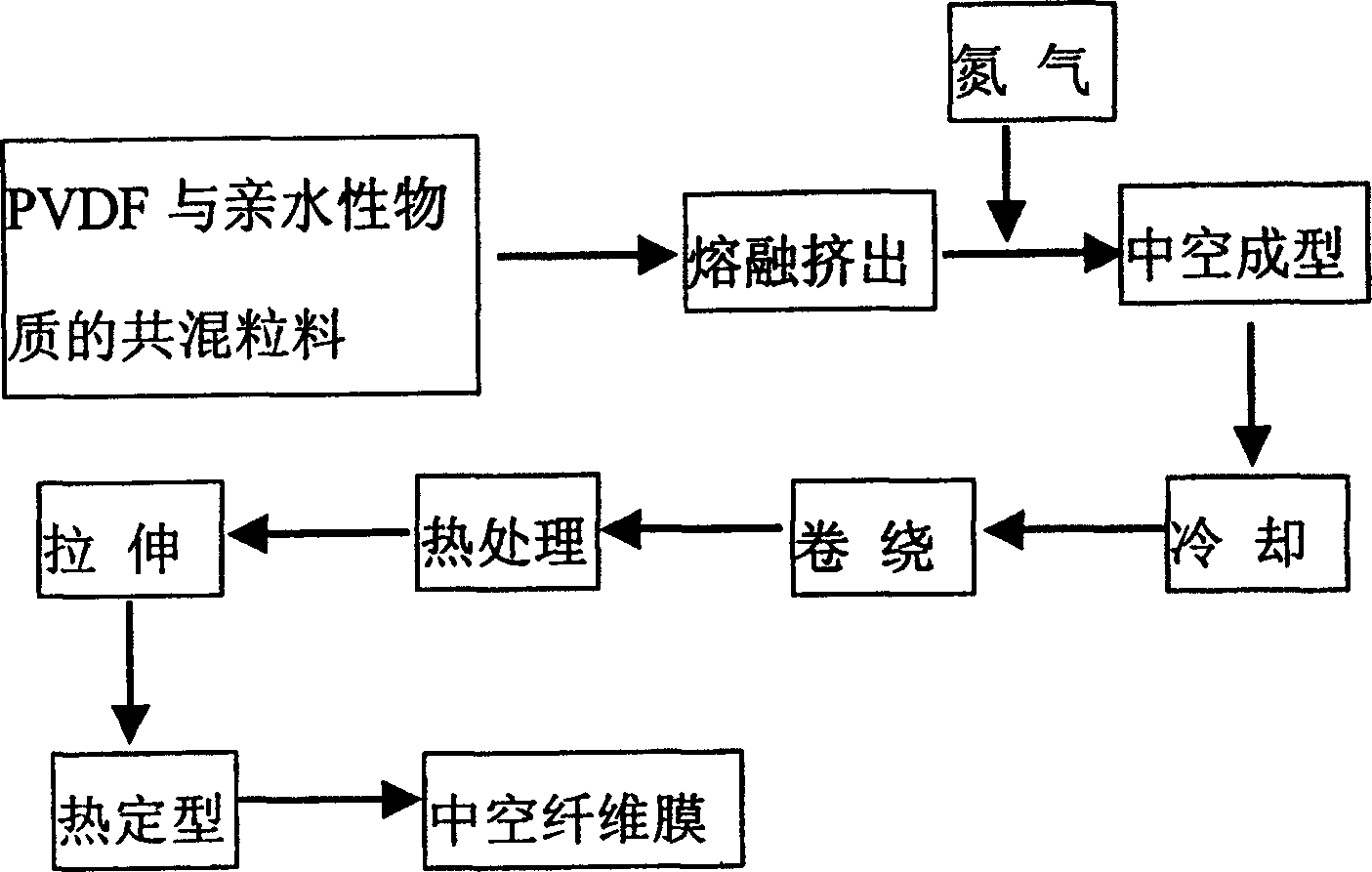

Method for preparing polyvinylidene fluoride hollow fiber microporous film by microscopic phase separating method

A technology of polyvinylidene fluoride and phase separation, which is applied in semipermeable membrane separation, chemical instruments and methods, membrane technology, etc. It can solve the problems of microporous membrane method without patent reports, etc., and achieves membrane production process and is easy to operate , small amount required, and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Polyvinylidene fluoride (Zhejiang Lantian Environmental Protection High-tech Co., Ltd., melt index 3.0g / 10min) and cellulose diacetate (Wuxi Chemical Research and Design Institute) were melt-blended at 200°C, and the weight percentage of cellulose diacetate The content is 0.03%, and granulated. Then the blended pellets are fed into a spinning machine, and the hollow fiber membrane is prepared through a melt spinning-stretching process. The spinning conditions are as follows: the hollow spinneret is a sleeve-type spinneret with an air supply pipe inside, nitrogen is fed into the central air supply pipe, and the pressure is 30 mm of water column. The spinning temperature of the spinneret was 215°C. The winding speed of the hollow fiber was 100 m / min, and the draft ratio was 1100. The prepared hollow fiber wound filaments were heat-treated at 125°C for 24h, and then stretched directly. The stretching conditions were: stretching at 90° C. at a stretching rate of 3 cm / min...

Embodiment 2

[0049] Polyvinylidene fluoride (Zhejiang Lantian Environmental Protection High-tech Co., Ltd., melt index 3.0g / 10min) and cellulose acetate-butyrate (Wuxi Chemical Research and Design Institute) were melt-blended at 210°C, and cellulose acetate-butyrate The weight percentage is 0.03%, and granulated. Then the blended pellets are fed into a spinning machine, and the hollow fiber membrane is prepared through a melt spinning-stretching process. The spinning conditions are as follows: the hollow spinneret is a sleeve-type spinneret with an air supply pipe inside, the central air supply pipe is fed with nitrogen, and the pressure is 33 mm of water column. The spinning temperature of the spinneret was 216°C. The winding speed of the hollow fiber was 140 m / min, and the draft ratio was 1500. The prepared hollow fiber wound filaments were heat-treated at 135°C for 12h, and then stretched directly. The stretching conditions were: stretching at 90° C. at a stretching rate of 4 cm / min,...

Embodiment 3

[0052] Polyvinylidene fluoride (Zhejiang Lantian Environmental Protection High-tech Co., Ltd., melt index 3.0g / 10min) and hydroxymethyl cellulose (Wuxi Chemical Research and Design Institute) were melt blended at 215 ° C, the weight of hydroxymethyl cellulose The percentage content is 0.04%, and granulated. Then the blended pellets are fed into a spinning machine, and the hollow fiber membrane is prepared through a melt spinning-stretching process. The spinning conditions are as follows: the hollow spinneret is a sleeve-type spinneret with an air supply pipe inside, the central air supply pipe is fed with nitrogen, and the pressure is 35 mm of water column. The spinning temperature of the spinneret was 224°C. The winding speed of the hollow fiber was 140 m / min, and the draft ratio was 1500. The prepared hollow fiber wound filaments were heat-treated at 140°C for 12h, and then stretched directly. Stretching conditions were: stretching at 90° C. at a stretching rate of 3 cm / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com