Hydrophilic modified preparation method for polyethylene hollow fiber microporous membrane

A polyethylene, hydrophilic technology, applied in chemical instruments and methods, fiber processing, membrane technology, etc., can solve the problems of harsh modification conditions, poor modification effect, cumbersome steps, etc., and achieve the membrane production process. And the effect of easy operation, small demand and simple film making process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

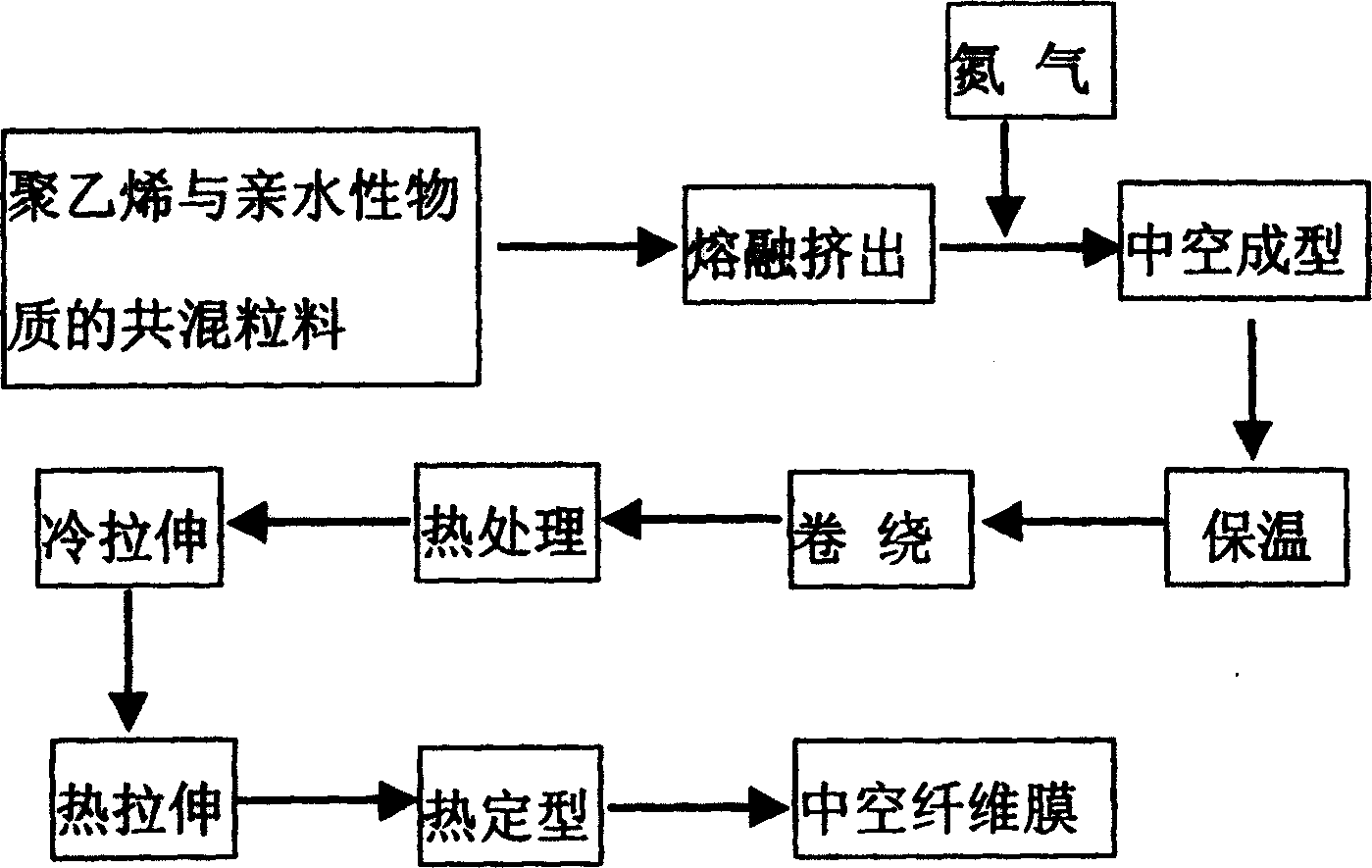

Method used

Image

Examples

Embodiment 1

[0058] Polyethylene resin (Japan Mitsui Petrochemical Co., Ltd., melt index 5.4g / 10min) and cellulose acetate-butyrate (Wuxi Chemical Research and Design Institute) were melt blended at 140°C, the weight percentage of cellulose acetate-butyrate 0.03%, and granulated. Then the blended pellets are fed into a spinning machine, and the hollow fiber membrane is prepared through a melt spinning-stretching process. The spinning conditions are as follows: the hollow spinneret is a sleeve-type spinneret with an air supply pipe inside, nitrogen is fed into the central air supply pipe, and the pressure is 15 mm of water column. The spinning temperature of the spinneret is about 169°C. The winding speed of the hollow fiber was 180 m / min, and the draft ratio was 1200. The prepared hollow fiber wound filaments were heat-treated at 105°C for 2h, and then stretched directly. Stretching conditions were as follows: cold stretching at 25° C. at a stretching rate of 12 cm / min, with a stretchin...

Embodiment 2

[0061] Polyethylene resin (Japan Mitsui Petrochemical Co., Ltd., melt index 5.4g / 10min) and cellulose acetate-butyrate (Wuxi Chemical Research and Design Institute) were melt blended at 150°C, the weight percentage of cellulose acetate-butyrate 0.04%, and granulated. Then the blended pellets are fed into a spinning machine, and the hollow fiber membrane is prepared through a melt spinning-stretching process. The spinning conditions are as follows: the hollow spinneret is a sleeve-type spinneret with an air supply pipe inside, nitrogen is fed into the central air supply pipe, and the pressure is 17 mm of water column. The spinning temperature of the spinneret is about 172°C. The winding speed of the hollow fiber was 200 m / min, and the draft ratio was 1300. The prepared wound hollow fiber was heat-treated at 110°C for 3h, and then stretched directly. Stretching conditions were as follows: cold stretching at 30° C. at a stretching rate of 17 cm / min, with a stretching ratio of ...

Embodiment 3

[0064] Polyethylene resin (Mitsui Petrochemical Co., Ltd., melt index 5.4g / 10min) and cellulose acetate-butyrate (Wuxi Chemical Research and Design Institute) were melt blended at 160°C, the weight percentage of cellulose acetate-butyrate 0.04%, and granulated. Then the blended pellets are fed into a spinning machine, and the hollow fiber membrane is prepared through a melt spinning-stretching process. The spinning conditions are as follows: the hollow spinneret is a sleeve-type spinneret with an air supply pipe inside, nitrogen is fed into the central air supply pipe, and the pressure is 19 mm of water column. The spinning temperature of the spinneret is about 178°C. The winding speed of the hollow fiber was 240 m / min, and the draft ratio was 1600. The prepared wound hollow fiber was heat-treated at 115°C for 2 hours, and then stretched directly. Stretching conditions were: cold stretching at 32° C. at a stretching rate of 27 cm / min, with a stretching ratio of 50%, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| stretching rate | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com