Pipeline temp-lowering system using circulating underground water for joint greenhouses

An underground water pipeline and circulation cooling technology, which is applied in greenhouse cultivation, horticulture, climate change adaptation, etc., can solve the problems of low cost, high cost, large steel consumption, etc., and achieve the low limit of high humidity climate conditions and low facility cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

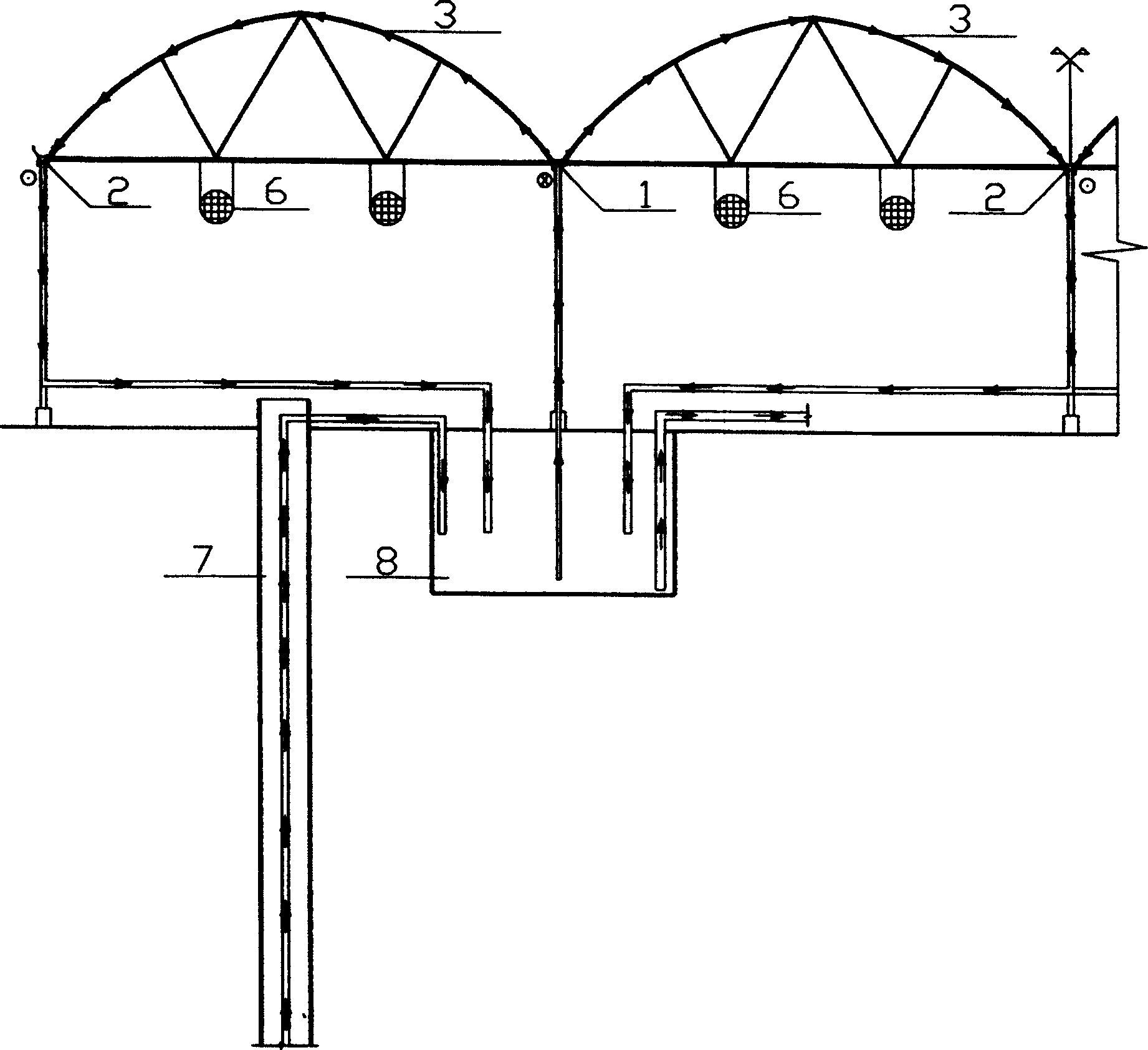

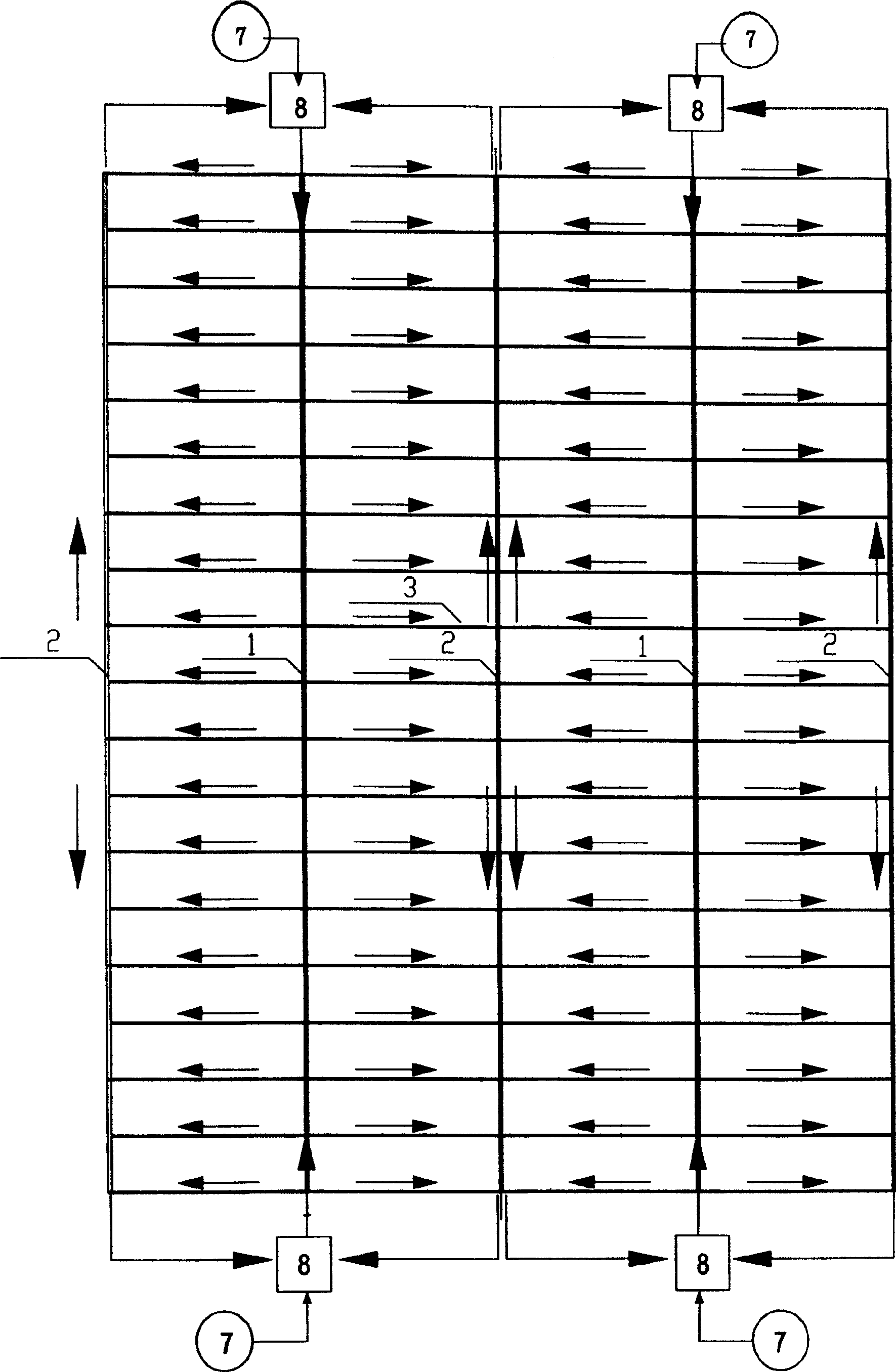

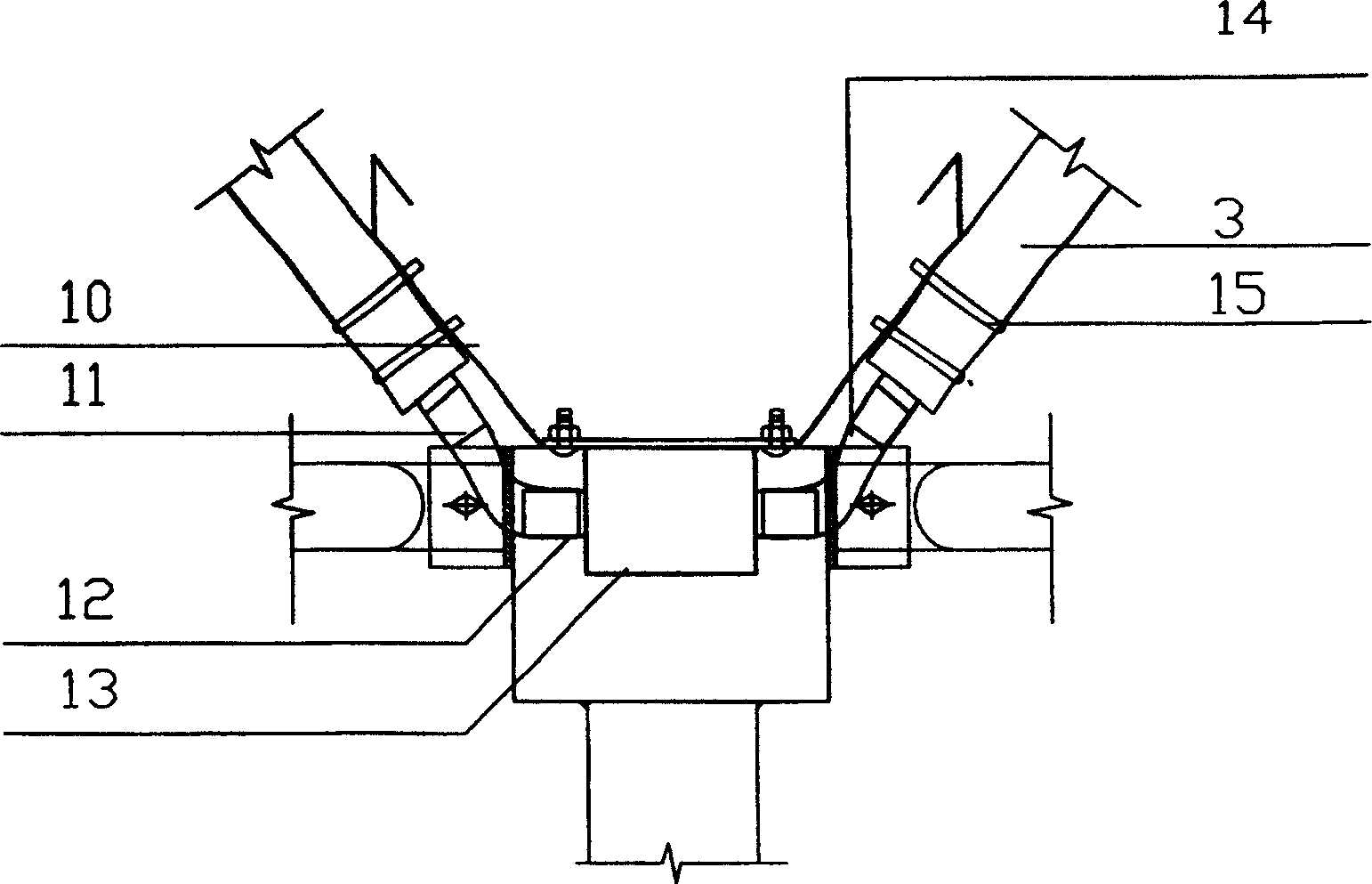

[0036] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the piping system uses structural members, including: the bottom beam 1 of the combined gutter that doubles as a water supply pipe, the bottom beam 2 of the combined gutter that doubles as a return pipe, and structural rods 3; the upper part of the combined gutter is a water collection tank 10. The lower part is the bottom beams 1 and 2 of the composite gutter which are respectively used as water supply pipes or return pipes;

[0037] Such as Figure 6 , Figure 7 , Figure 8As shown, its pipeline system utilizes the heating pipeline part, including: heating pipeline bracket 21, hook 22, hanging chain 23, outdoor water intake reversing device; the heating pipeline system bottom is set as a movable heating pipeline bracket 21. Connect the hook 22 to the side of the greenhouse heating pipeline 4, connect the hanging chain 23 to the hook 22, and hang it on the upper frame of the greenhouse; the outdoor wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com