Fuel jetting valves

A technology for fuel injection valves and fuel passages, which is applied to fuel injection devices, charging systems, engine components, etc., and can solve the problems of fuel particle sacrifice, difficulty in spraying orifice plates, and rising production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

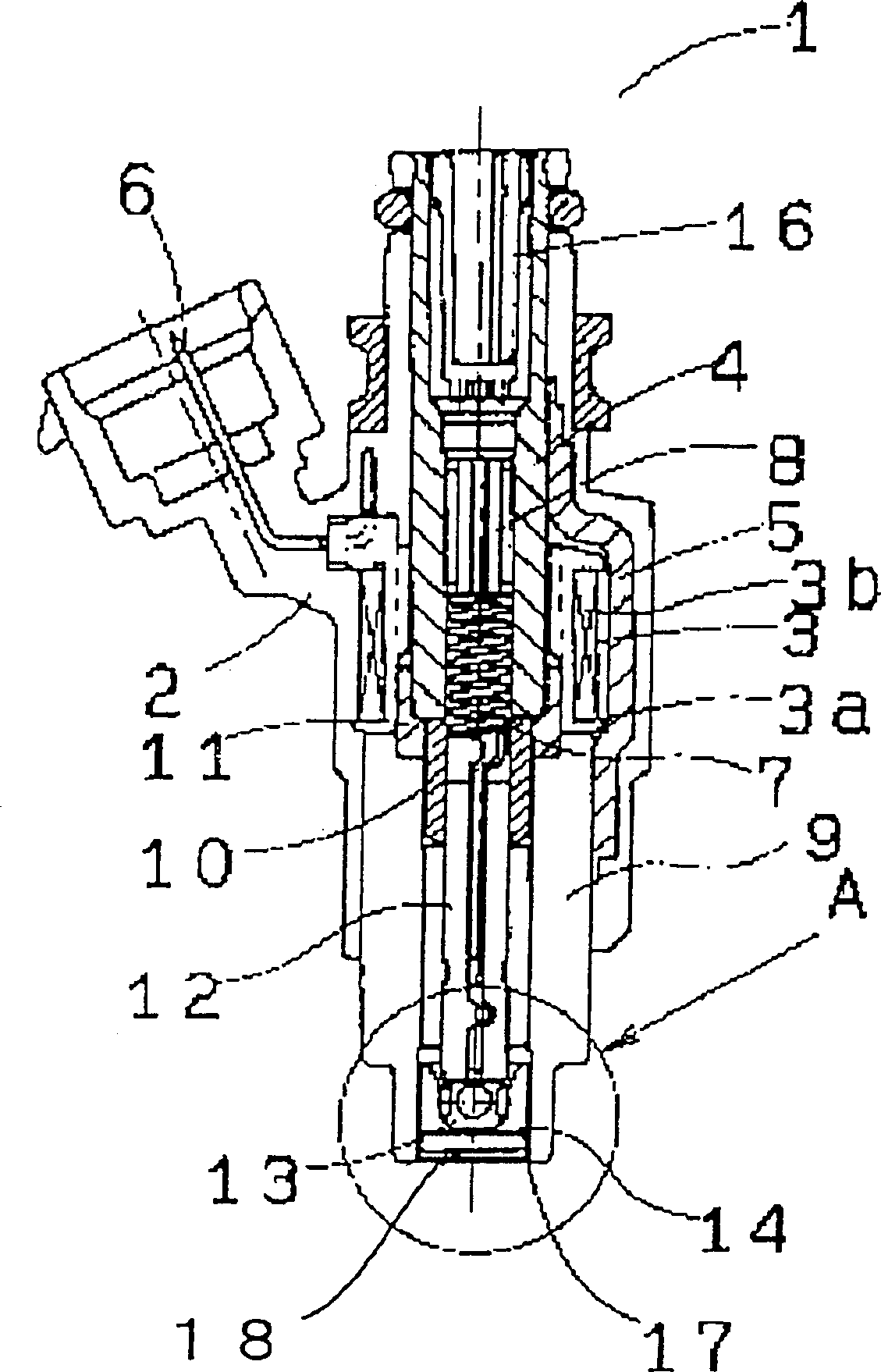

[0021] The first embodiment of the present invention will be described below. figure 1 The first embodiment of the present invention is a side cross-sectional view showing the overall structure of the fuel injection valve 1 . The fuel injection valve 1 is integrally formed with an electromagnetic coil 3 , a fixed iron core 4 , and a metal plate 5 constituting a magnetic channel arranged inside a resin housing 2 . The electromagnetic coil 3 is composed of a resin-made bobbin 3 a, a coil 3 b wound on the outside thereof, and a terminal 6 provided for connection to the outside, and is integrally molded with the resin-made casing 2 .

[0022] An adjuster 8 for adjusting the compression spring 7 is fixed inside the fixed iron core 4 . One end of the two metal plates 5 constituting the magnetic channel is fixed on the fixed iron core 4 by welding, and the other end is welded on the electromagnetic tube 9 constituting the magnetic channel. A movable iron core 10 provided inside th...

no. 2 Embodiment

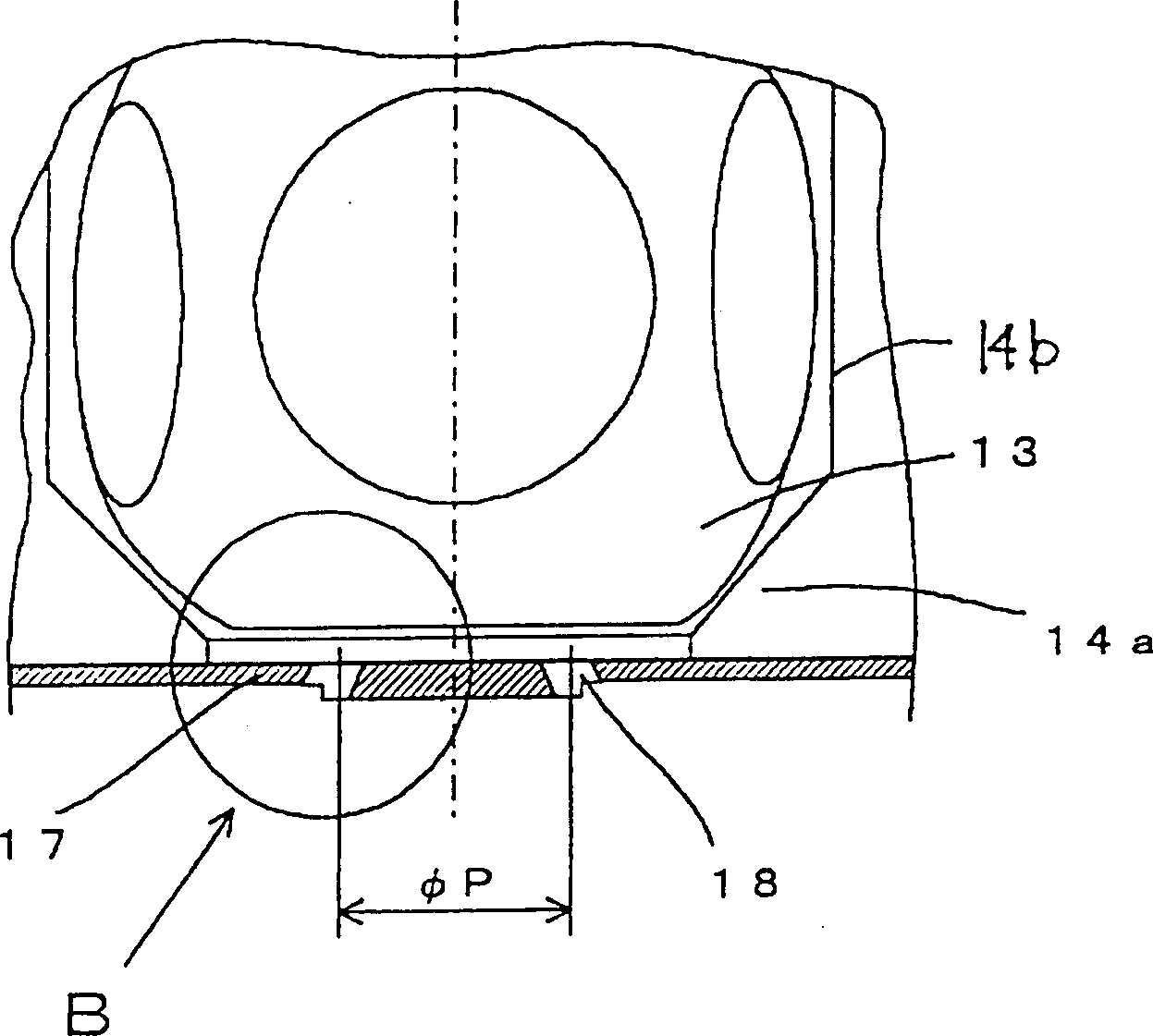

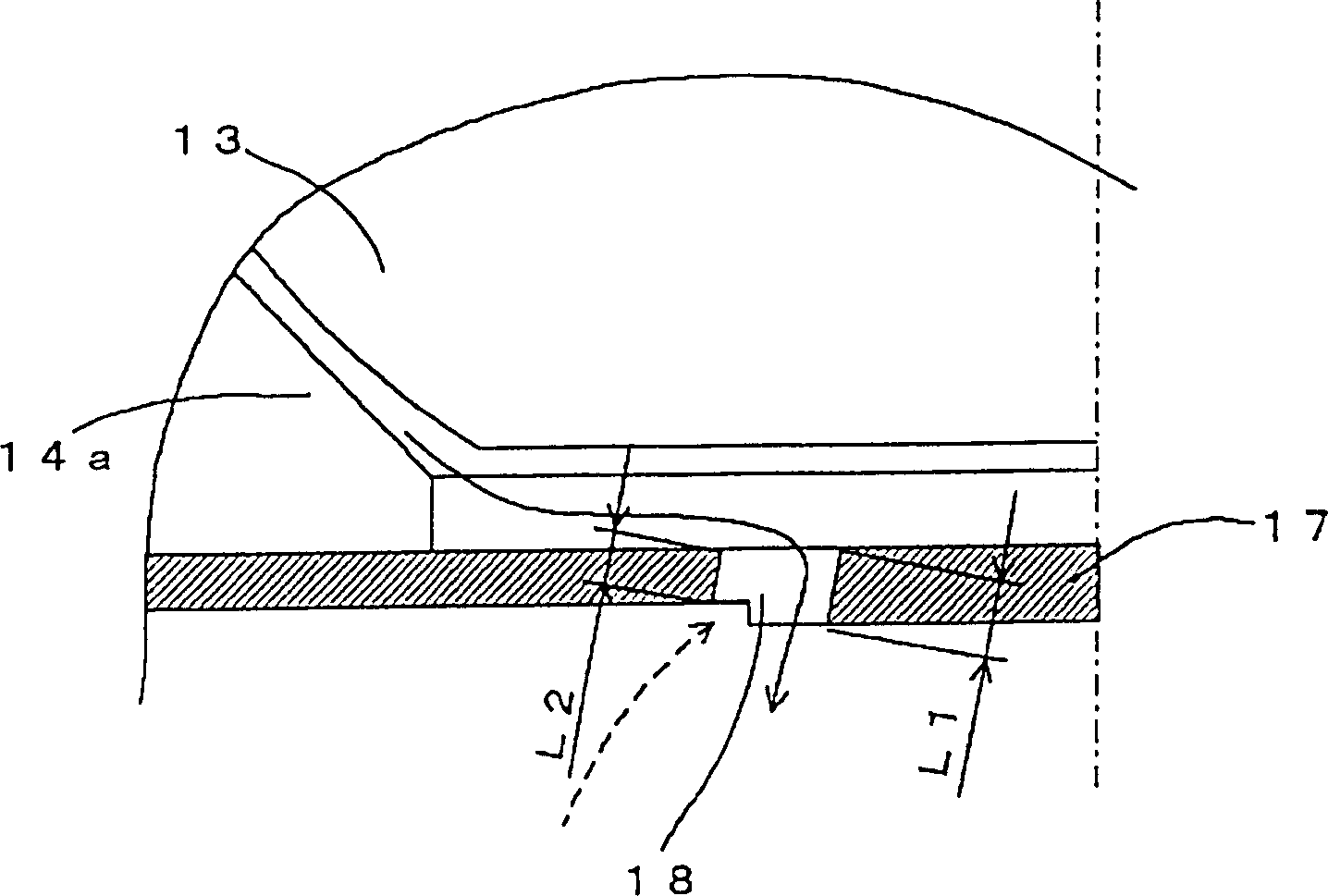

[0030] In the above-described first embodiment, the thickness of the inner peripheral side of the orifice plate 17 is larger than the thickness of the outer peripheral portion, and the injection holes are formed across the stepped portion where the thickness of the nozzle changes, but the fuel pressure is large, and it is necessary to ensure the injection orifice plate. In the case of strength of 17, it is also possible to constitute Figure 5 Orifice plate 17 shown.

[0031] like Figure 5 As shown, the injection hole plate 17 is formed with an annular groove 19b centered on the axis of the fuel injection valve, and the injection hole 18 is formed with a radially inner surface spanning the groove 19b. By providing the injection hole 18 in this way, a part of the outer side in the radial direction of the injection hole 18 is in a notch state, and a relationship of L1>L2 can be established.

[0032] Such an orifice plate is the same as the orifice plate of the above-described...

no. 3 Embodiment

[0035] In the above-mentioned first and second embodiments, one stepped portion or one groove is provided for the plurality of injection holes. Image 6 As shown, one concave portion 19c is provided for one injection hole 18, each injection hole 18 is formed across the radially inner surface of the concave portion 19c, and a part of the radially outer side of the injection hole 18 is in a notch state, so that L1> L2 relationship.

[0036]Like the orifice plate of the above-described first embodiment, such an orifice plate can be manufactured with simple steps, such as the step of forming the concave portion by punching or the like and the step of forming the orifice by punching or the like, without sacrificing the orifice. The strength of the plate and the directionality of the fuel injection make it possible to obtain an electromagnetic fuel injection valve that atomizes the fuel spray. Further, only the portion where the plate thickness is reduced is in the groove 19b, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com