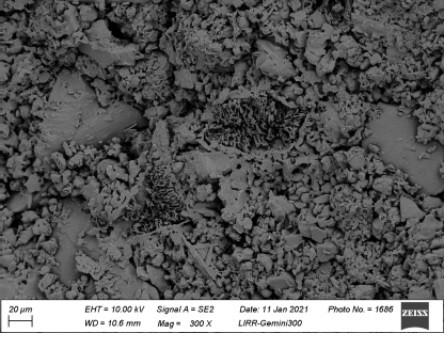

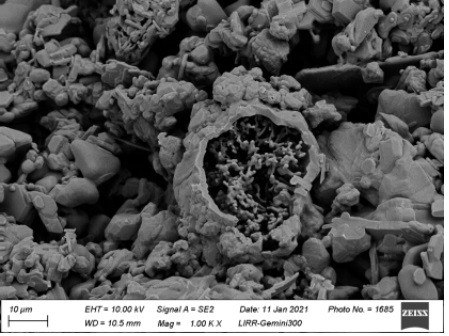

Preparation method of calcium hexaluminate-magnesium aluminate spinel multiphase material with spherical shell-sponge structure

A technology of magnesium aluminum spinel and calcium hexaaluminate, which is applied in the field of preparation of spherical shell-sponge structure calcium hexaaluminate-magnesium aluminum spinel composite materials, can solve the problem that the thermal shock stability is not as good as that of conventional corundum- Mullite, cordierite-mullite, high thermal expansion coefficient, etc., to achieve the effect of improving thermal shock stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: The proportion of each component is (mass percentage): 5-0.088mm heavy calcium hexaaluminate particles 70%, calcium hexaaluminate fine powder 26%, alumina micropowder 3%, 0.5-0.1mm electrofusion Magnesium Oxide Granules 1%.

[0018] In Example 1, 2.8% of the pulp solution is first added to the particle part, mixed evenly with a wheel mill, and then the fine powder part mixed with a V-shaped mixer is added to the wheel mill, and the material is discharged after stirring for 5 to 10 minutes. It is molded by vibration and pressure, and dried at 110°C. After heat preservation at 1100°C for 6 hours in a reducing atmosphere, then return to an oxidizing atmosphere, and firing at 1750°C for 8 hours, a calcium hexaaluminate-magnesium aluminum spinel composite material with a spherical shell-sponge structure was obtained. The normal temperature compressive strength is 152MPa. According to the DIN 51068:2008 standard, the number of water-cooled thermal shocks at 1100°...

Embodiment 2

[0021] Example 2: The proportion of each component is (mass percentage): 5-0.088mm heavy calcium hexaaluminate particles 60%, calcium hexaaluminate fine powder 16%, alumina micropowder 18%, 0.2-0.1mm electrofusion Magnesium oxide particles 6%.

[0022] In Example 2, first add 3% water-based resin solution to the granule part, mix evenly with a wheel mill, then add the fine powder part mixed with a V-type mixer to the wheel mill, stir for 5 to 10 minutes, and then discharge , formed by a friction brick press and dried at 110°C. After 1200°C reducing atmosphere for 3 hours, then recovering the oxidizing atmosphere, and 1650°C kiln heat preservation for 8 hours, the calcium hexaaluminate-magnesium aluminum spinel composite material with spherical shell-sponge structure was obtained. The normal temperature compressive strength is 120MPa. According to the DIN51068:2008 standard, the number of water-cooled thermal shocks at 1100°C can reach 25 times.

Embodiment 3

[0025] Example 3: The proportion of each component is (mass percentage): 70% of heavy calcium hexaaluminate particles of 5-0.088mm, 18% of calcium hexaaluminate fine powder, 9% of alumina fine powder, 0.1-0.074mm electrofusion Magnesium oxide fine powder 3%.

[0026] In embodiment three, first add 1% dextrin solution and 1% water-based resin solution to the granule part, mix evenly with a wheel mill, then add the fine powder part mixed with a V-type mixer into the wheel mill, and stir for 5~ After 10 minutes, the material is discharged, formed by vibration and pressure, and dried at 110°C. After heat preservation at 1150°C for 4 hours in a reducing atmosphere, then return to an oxidizing atmosphere, and firing at 1600°C for 8 hours, a calcium hexaaluminate-magnesium aluminum spinel composite material with a spherical shell-sponge structure was obtained. The compressive strength at room temperature is 83MPa. According to the DIN 51068:2008 standard, the number of water-cooled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com