Automatic bicycle

A technology for automatic two-wheeled vehicles and pipes, applied to bicycles, motor vehicles, bicycle racks, etc., can solve the problems of reduced riding comfort, achieve the effects of improving riding comfort, increasing productivity, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below, refer to Figure 1- Figure 25 Examples of the present invention will be described.

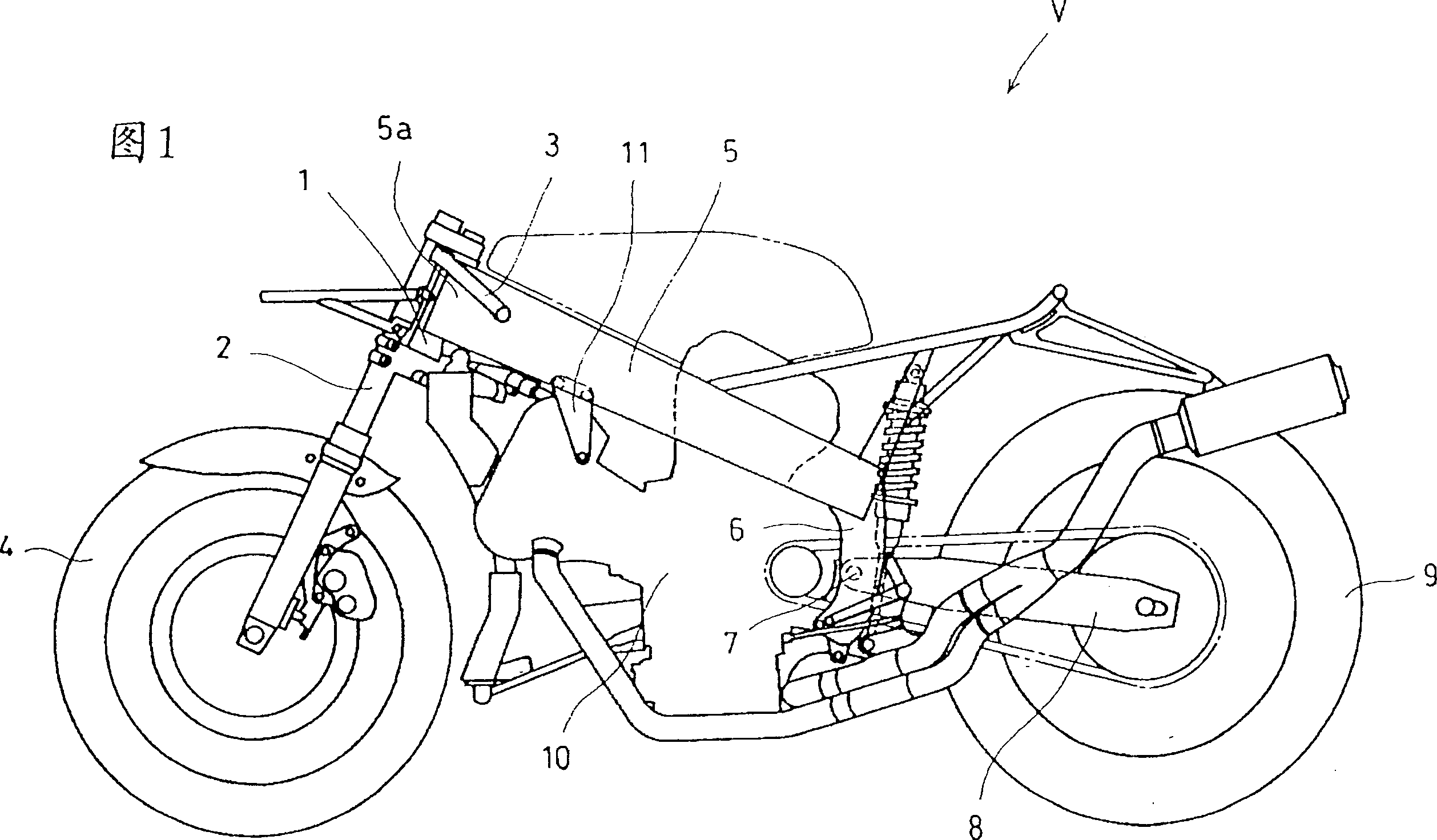

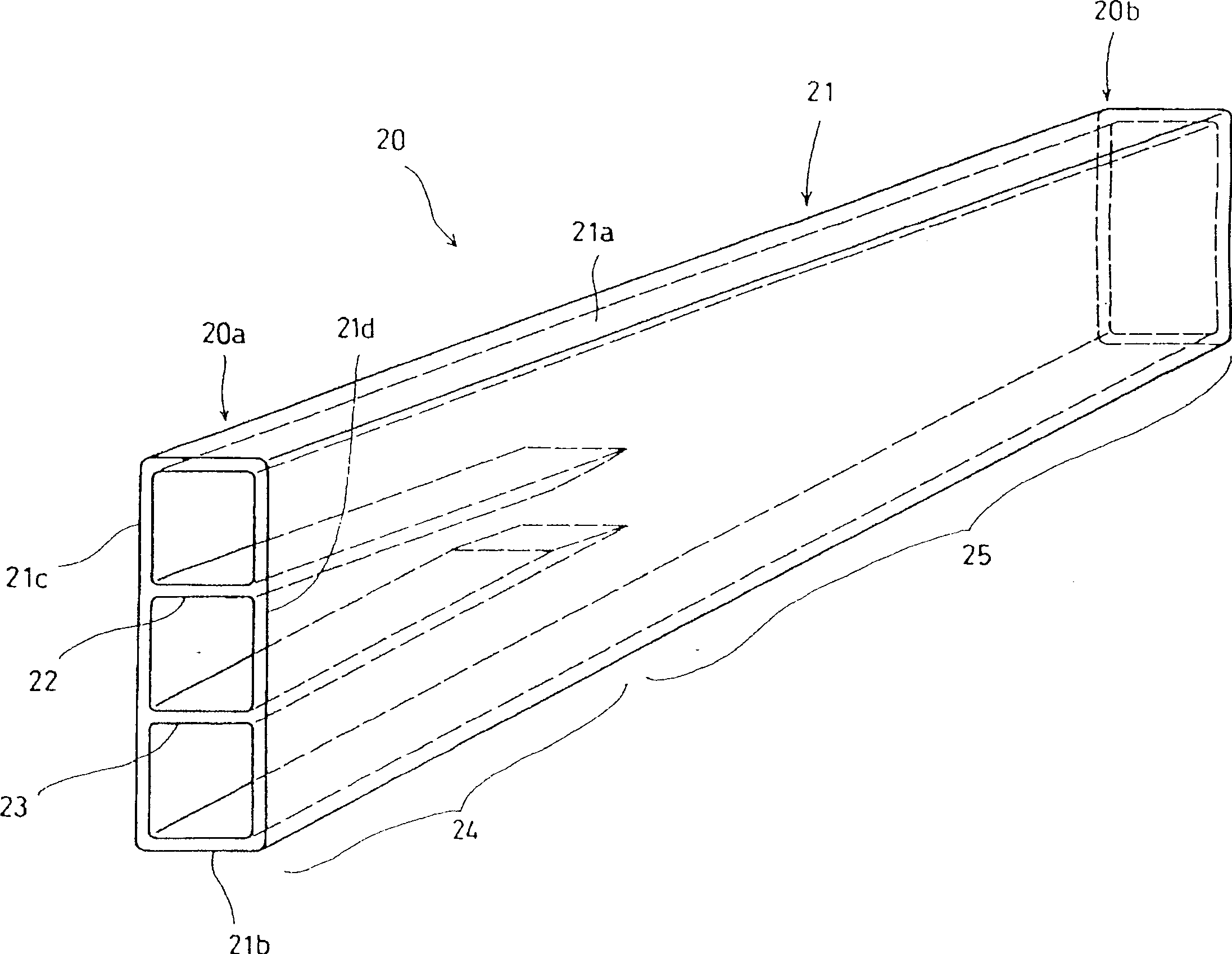

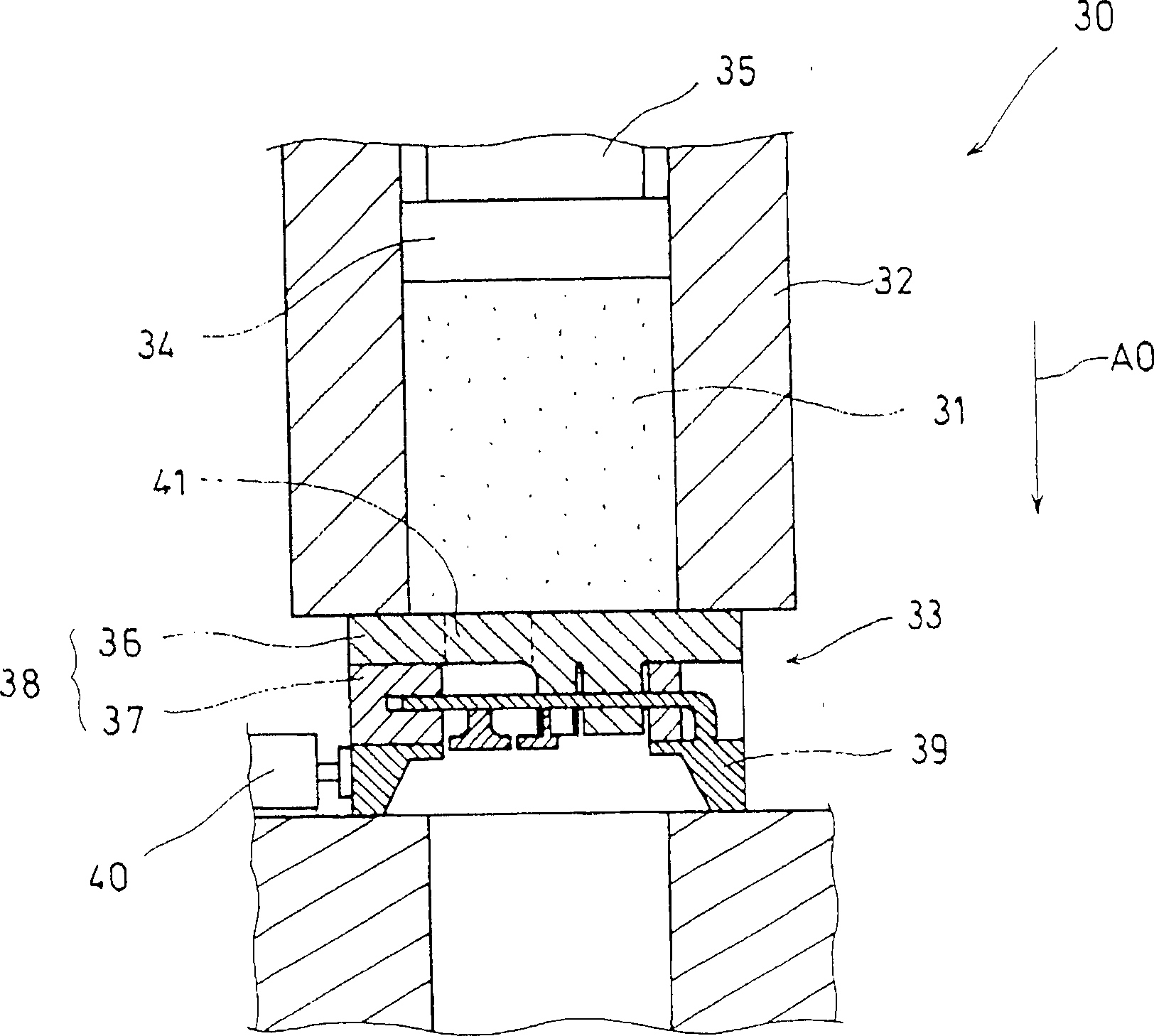

[0038] 1 to 10 show a first embodiment of the present invention, and Fig. 1 is a schematic left side view of a motorcycle V according to the present invention. In the motorcycle V, a handle 3 is provided at the upper end of a front fork 2 rotatably supported by a head pipe 1 , and a front wheel 4 is pivotally supported at the lower end thereof. A pair of left and right main pipes 5 whose front ends are connected to the head pipe 1 extend left and right while extending diagonally downward from the rear of the vehicle body in a bilaterally symmetrical manner, and are connected near the rear end by a cross pipe (not shown). . A pair of left and right pivot plates 6 are respectively connected to the rear ends of the two main pipes 5, and on the pivot 7 supported by the two pivot plates 6, the rear fork pivoting the rear wheel 9 is supported freely swinging up and down. 8. The fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com