Microraster structure

A micro-grating and grating technology, applied in the field of micro-grating structures, can solve problems such as poor actuation stability and poor synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

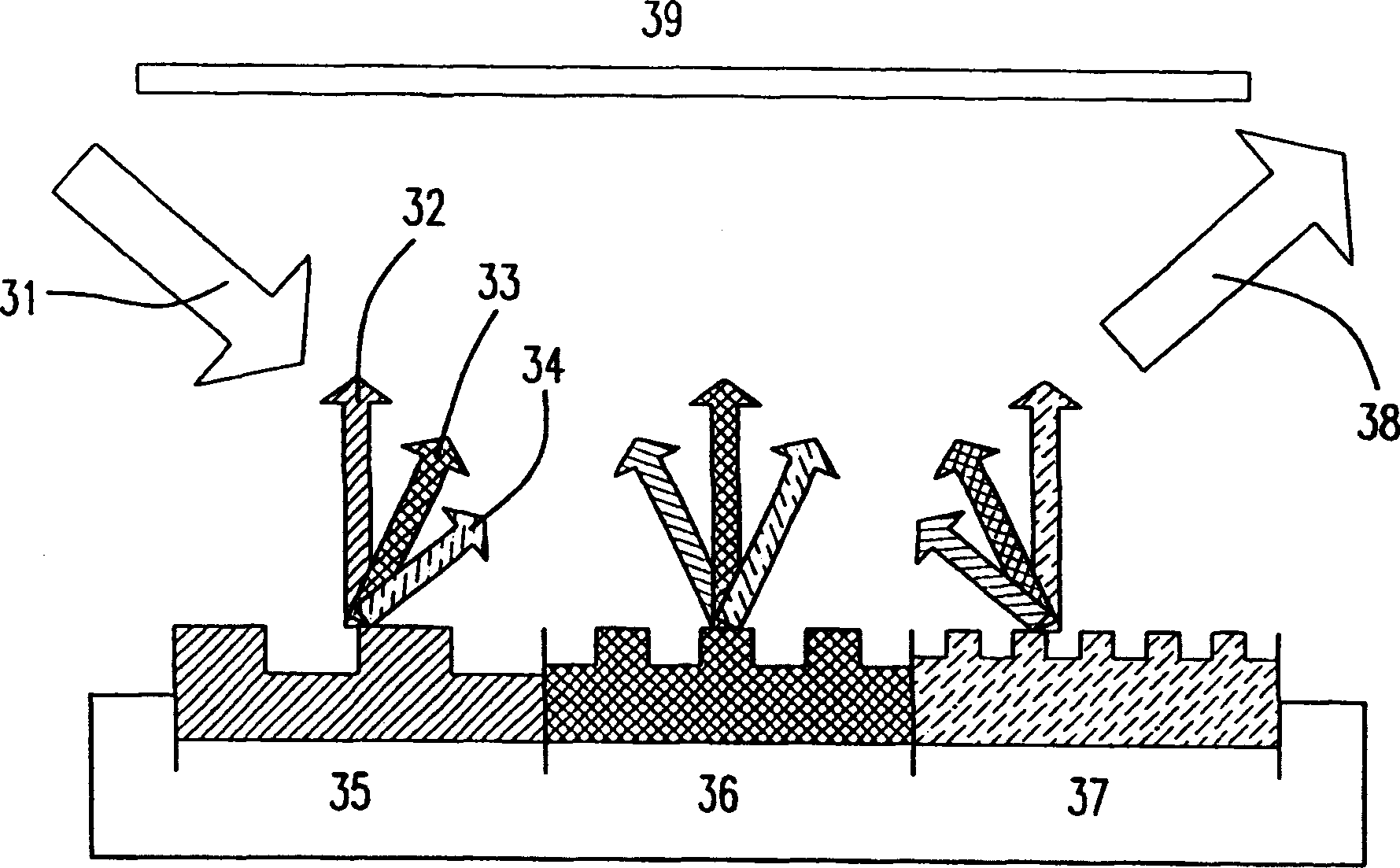

[0065] see Figure 6 , which is a top view of a preferred implementation of a micro-grating structure in the present invention. The micro-grating structure is composed of a semiconductor substrate 61, multiple pairs of structural pillars (wherein each pair of structural pillars is composed of a first structural pillar 62 and a second structural pillar 63), a plurality of gratings 64, a plurality of gaps 65, a first A support portion 66 and a second support portion 67 are formed, wherein the grating 64 also has a first torsion bar 641 , a second torsion bar 642 , a third torsion bar 643 and a fourth torsion bar 644 . The micro-grating structure is made of silicon as the material of the semiconductor substrate 61, and a plurality of gratings 64 are arranged between the first structural pillar 62 and the second structural pillar 63 of each pair of structural pillars, wherein each grating 64 is Adjacent to each other with a gap 65 less than 2 μm wide, and each grating 64 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com