Testing mask structure

A technology for testing masks and regions, which is applied in the fields of optics, instruments, and photolithography on patterned surfaces, etc. It can solve problems such as product profile degradation and inaccurate margin adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The method of the present invention will be described in detail with reference to the drawings.

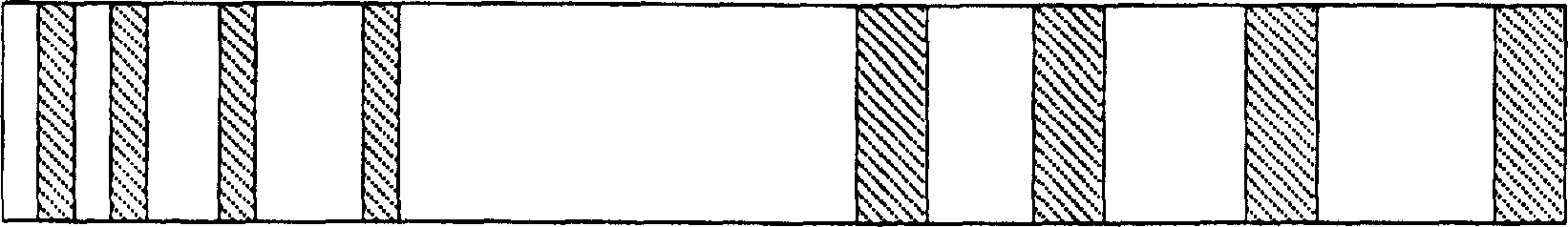

[0021] According to the present invention, a novel test mask structure uses an array pattern with a ratio of 1:1 to the final product to combine with the existing test mask pattern according to a specific area ratio to achieve a desired predetermined pattern density.

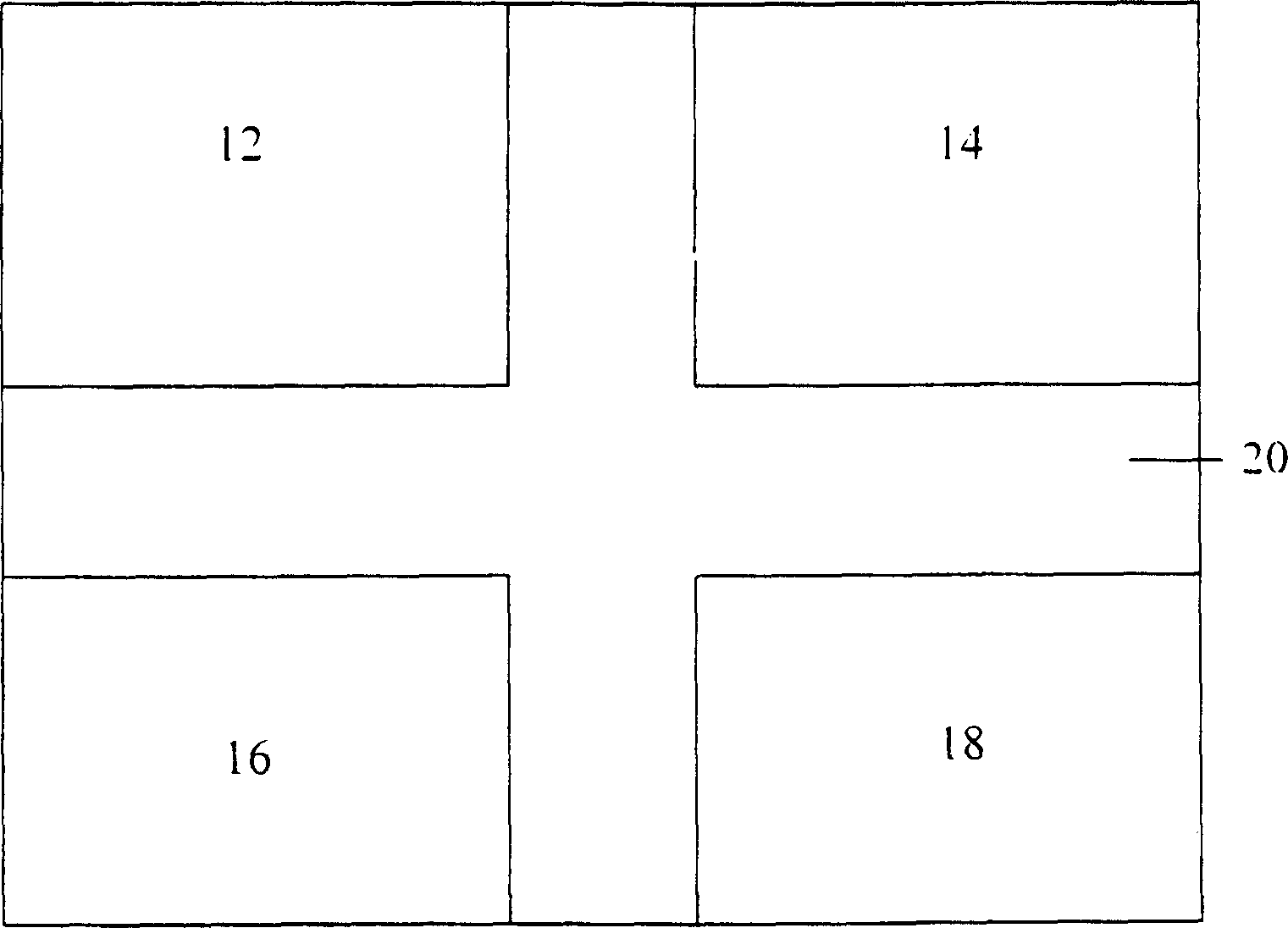

[0022] like figure 2 As shown, according to an embodiment of the present invention, the test mask structure includes array pattern regions 12, 14, 16 and 18 with a ratio of 1:1 to the line width of the final product (because the line width and line spacing are 1:1, The pattern density is 50%), and the cross region 20 in the structure is the existing test mask pattern region. By adjusting the 1:1 ratio of the total area of the product array pattern areas 12 , 14 , 16 and 18 to the area of the existing test mask pattern area 20 , the desired pattern density can be obtained. Its formula is as follows:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com