Flavour removing technique and device for vegetable oil without moisture removed

A vegetable oil and deodorization technology, applied in the field of vegetable oil processing technology and equipment, can solve the problems of shortening the shelf life of oil and slow heating, and achieve the effects of prolonging the shelf life, reducing equipment investment and prolonging the quality of the oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

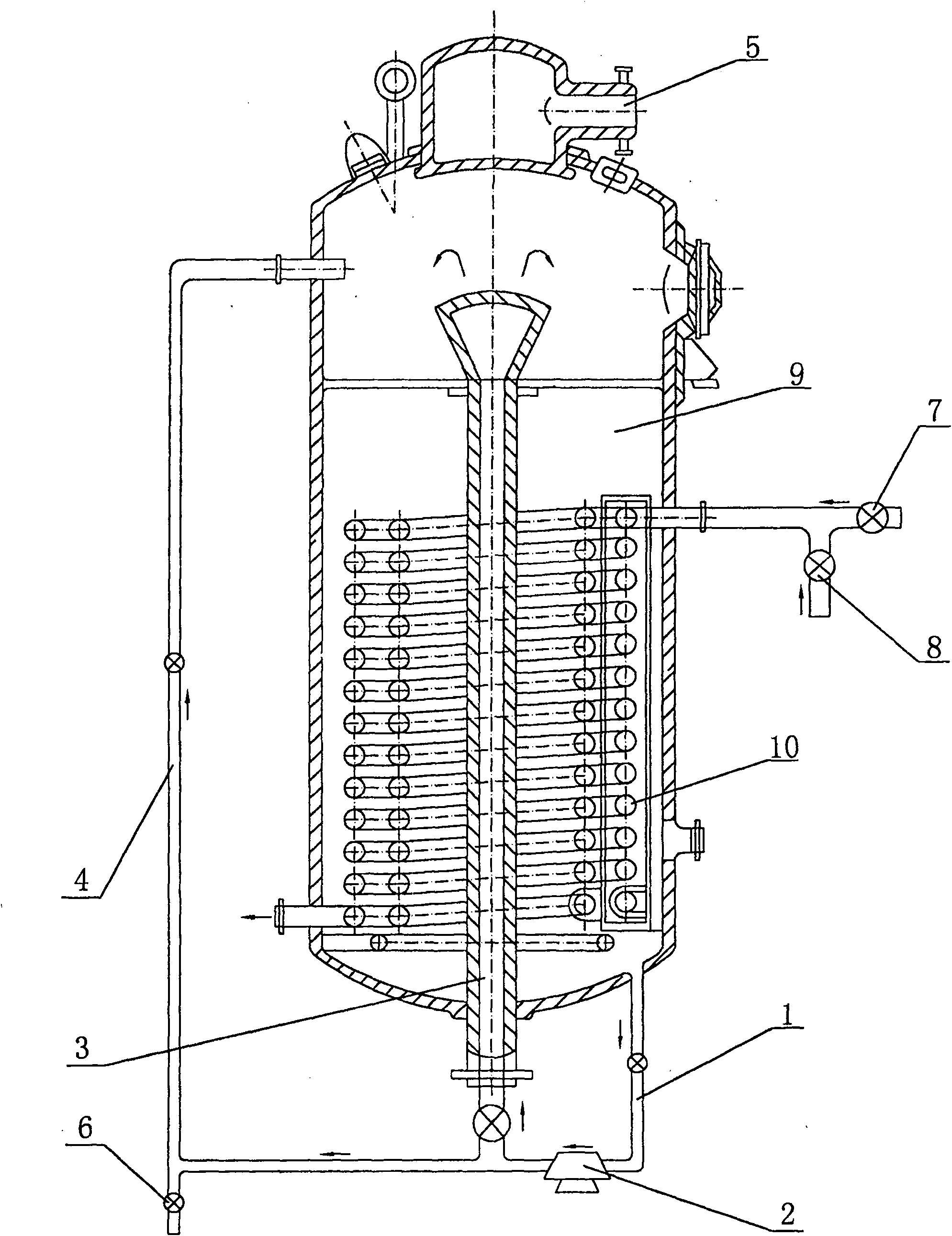

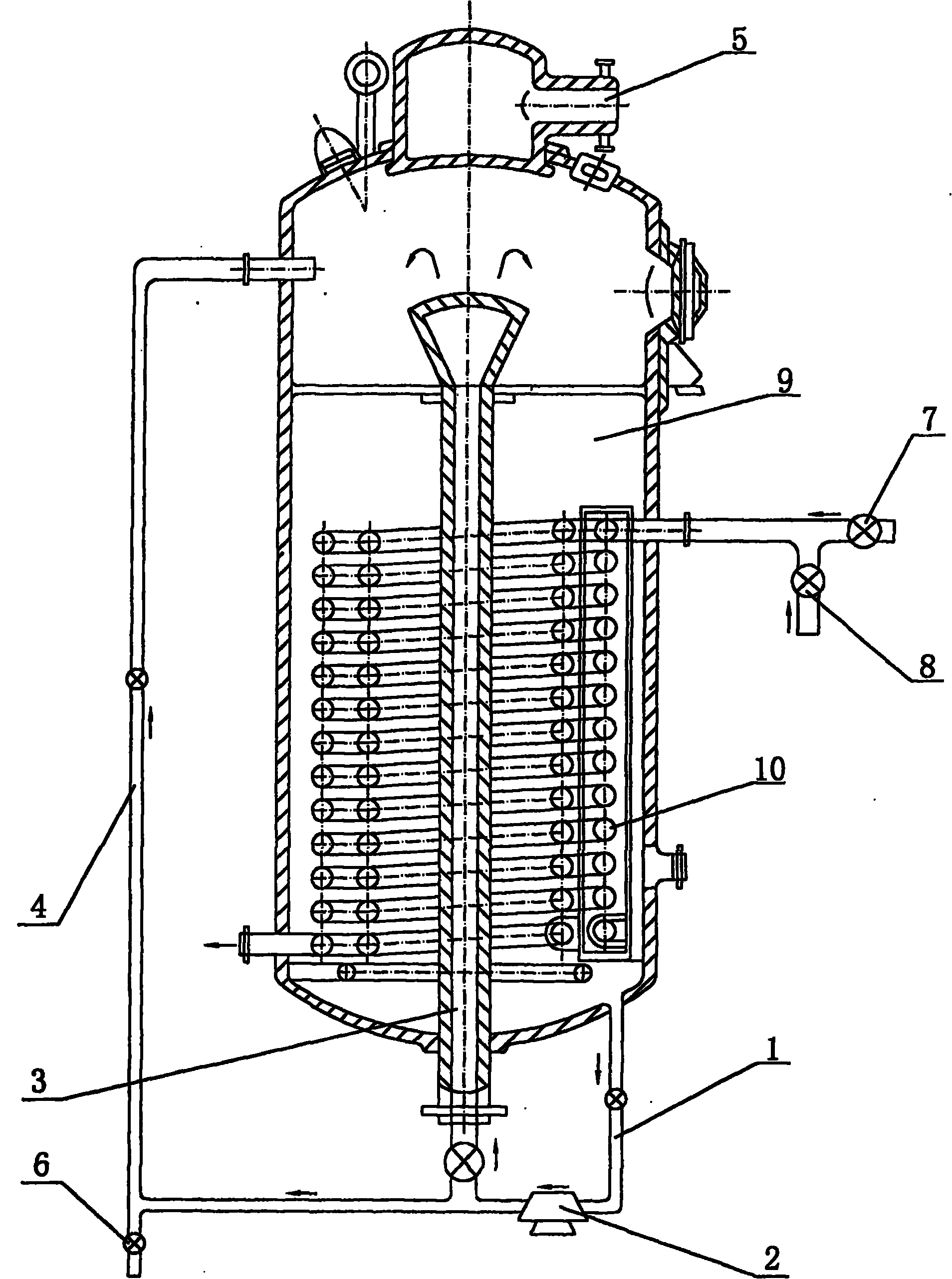

[0015] Referring to the accompanying drawings, the vegetable oil deodorizing tank without water residue in the figure includes a vertical working chamber 9, a vacuum connection port 5 is arranged on the top cover of the working chamber, and a heating coil 10 is arranged in the tank; The feature is: an oil inlet pipe 3 extends from bottom to top in the center of the working chamber, the lower end of the oil inlet pipe is connected to the oil outlet pipe 1 through a valve, and the bottom of the working chamber is connected to the gear pump 2 and the oil outlet pipe through a valved pipe.

[0016] The inlet end of the heating coil 10 is respectively connected to the cooling water inlet pipe and the hot air inlet pipe through a valve.

[0017] The upper chamber of the working chamber 9 is connected with the oil outlet pipe 1 through an oil return pipe with a valve.

[0018] Below in conjunction with accompanying drawing, the present invention is further described:

[0019] 1. Tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com