A device for compressing shredded tobacco to a specified bulk density

A technology of bulk density and shredded tobacco, which is applied in the field of tobacco, can solve problems such as the measurement of thermal physical property data of shredded tobacco or tobacco leaf samples, the difficulty of placing test probe measuring devices, and the complicated cigarette processing process, so as to facilitate spreading and compression, and the data is true and effective , the effect of uniform density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

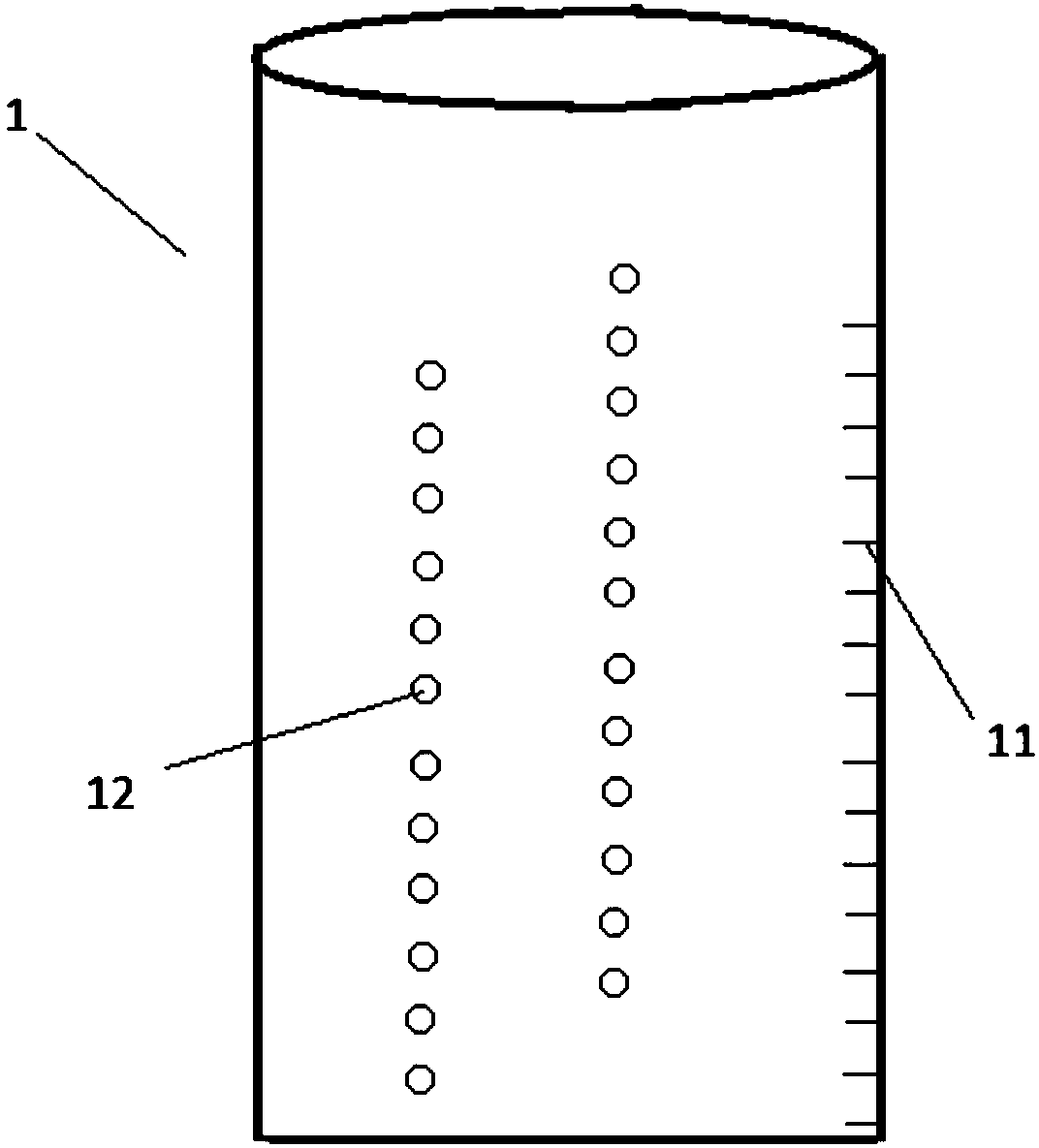

[0032] Embodiment 1: shredded tobacco compression

[0033] Set tobacco bulk density: 200kg / m 3 , the diameter of the shredded tobacco holding device is 10cm, and the height of compression is set to 6cm, then the required shredded tobacco mass is calculated to be 94.2g.

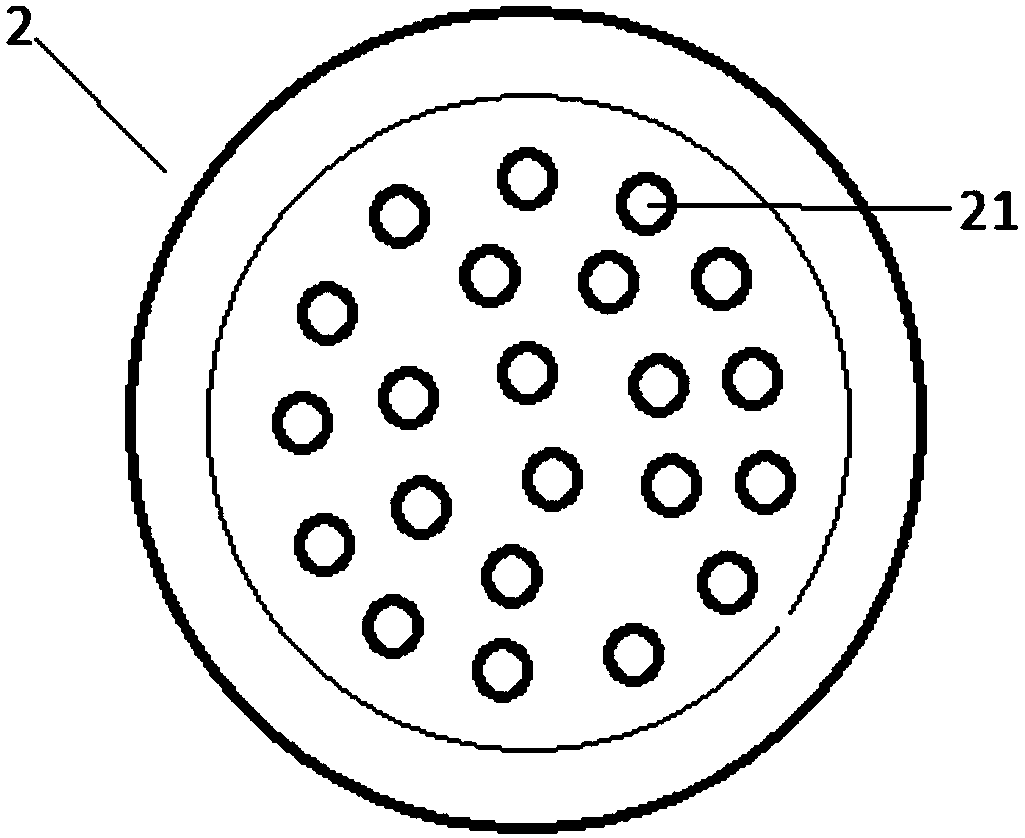

[0034] Under constant temperature and humidity conditions, weigh 94.2g of shredded tobacco, and slowly throw the shredded tobacco in the shredded tobacco holding device through the shredded tobacco throwing device. Since the shredded tobacco falls slowly, the shredded tobacco will be evenly spread on the bottom of the shredded tobacco holding device. It presents a similar natural accumulation state in the process of production and processing. Then take off shredded tobacco throwing device, put into compression device, according to the packing density of setting, the height of the compressed tobacco block is 6cm, and the weight bar is fixed on the scale indicator line place that depression bar sets. After a p...

Embodiment 2

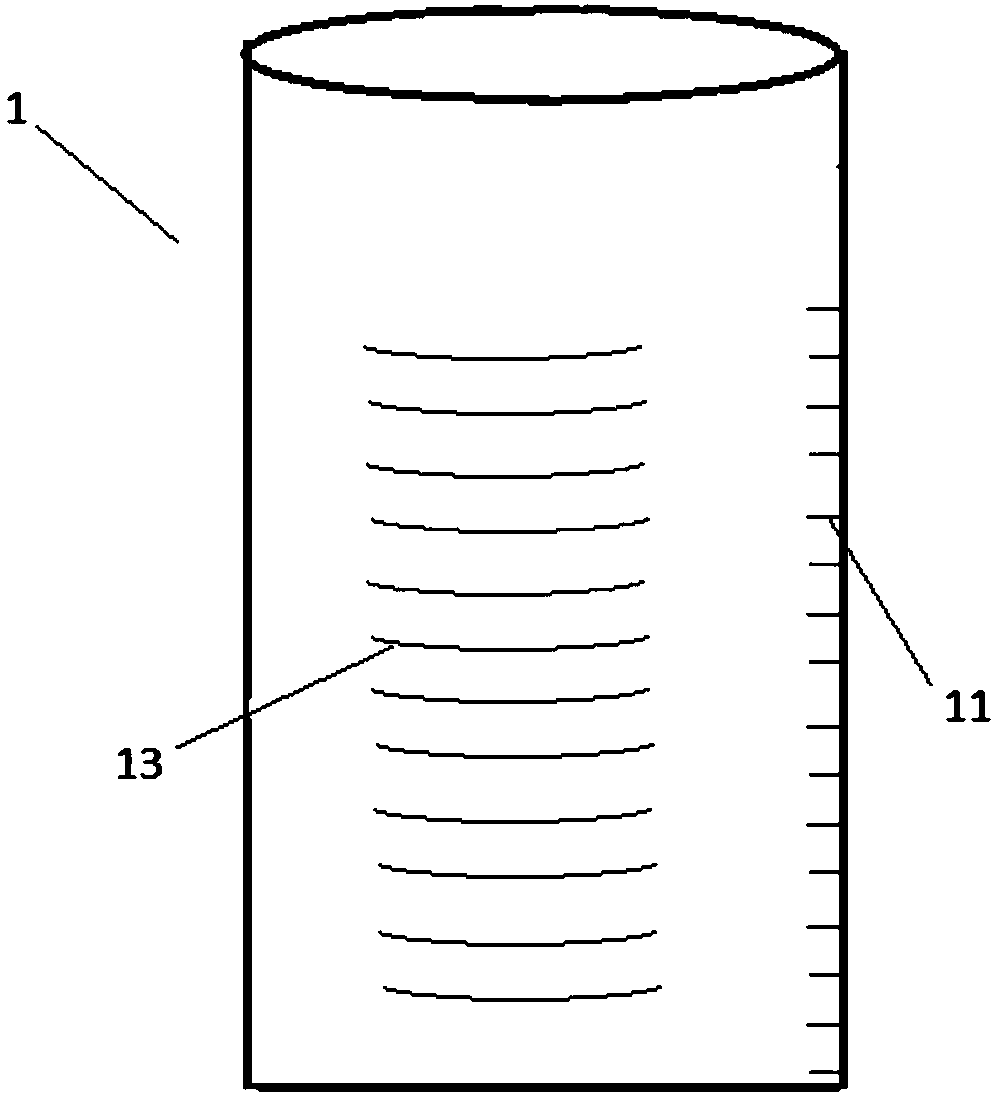

[0035] Embodiment 2: sheet tobacco compression

[0036] Set the bulk density of laminar smoke: 200kg / m 3 , the diameter of the shredded tobacco holding device is 20cm, and the compression height is set at 8cm, then the mass of tobacco sheet required is calculated as 502.4g.

[0037] In the constant temperature and humidity chamber, weigh 502.4g of tobacco flakes, and slowly throw the flakes of tobacco in the shredded tobacco holding device through the shredded tobacco throwing device. Since the shredded tobacco falls slowly, the shredded tobacco will be evenly spread on the shredded tobacco The bottom of the storage device presents a similar natural accumulation state during the production and processing process. Then take off shredded tobacco throwing device, put into compression device, according to the packing density of setting, the tobacco piece height of being compressed is 8cm, weight bar is fixed on the scale indicator line place that depression bar sets. After a per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com