Micro image technique in use for encoding and arranging mask type ROM

A read-only memory and photolithography technology, applied in the field of photolithography, can solve the problems of increasing the difficulty and manufacturing cost of reticle, time-consuming reticle production, and difficulty in improving reticle pattern, so as to avoid deviation and reduce manufacturing. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

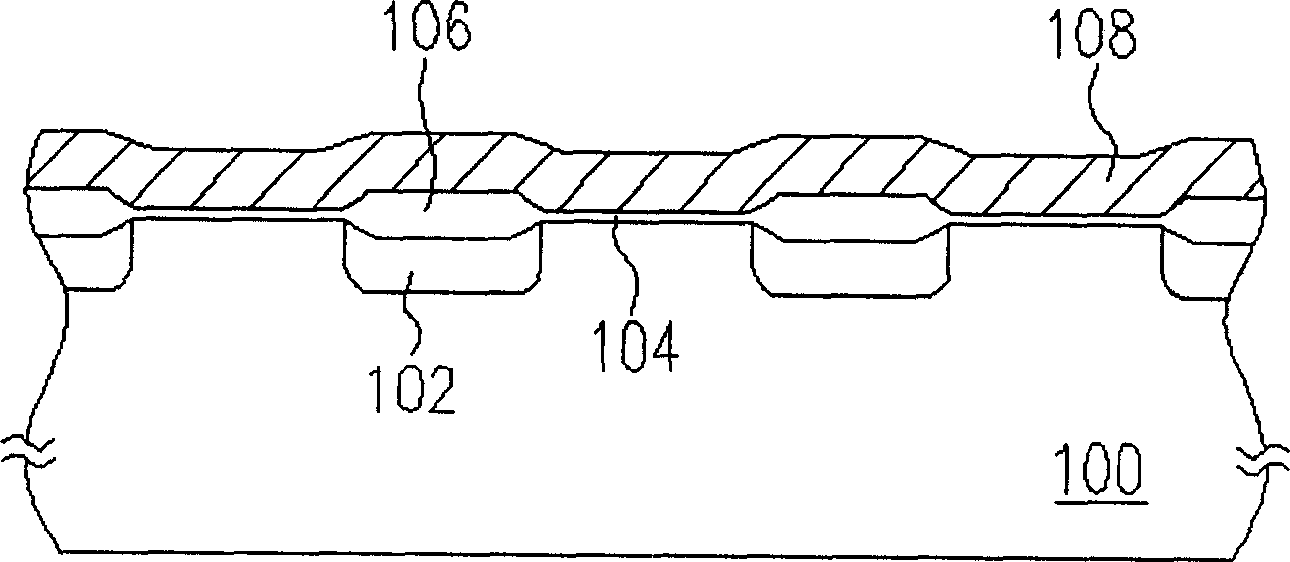

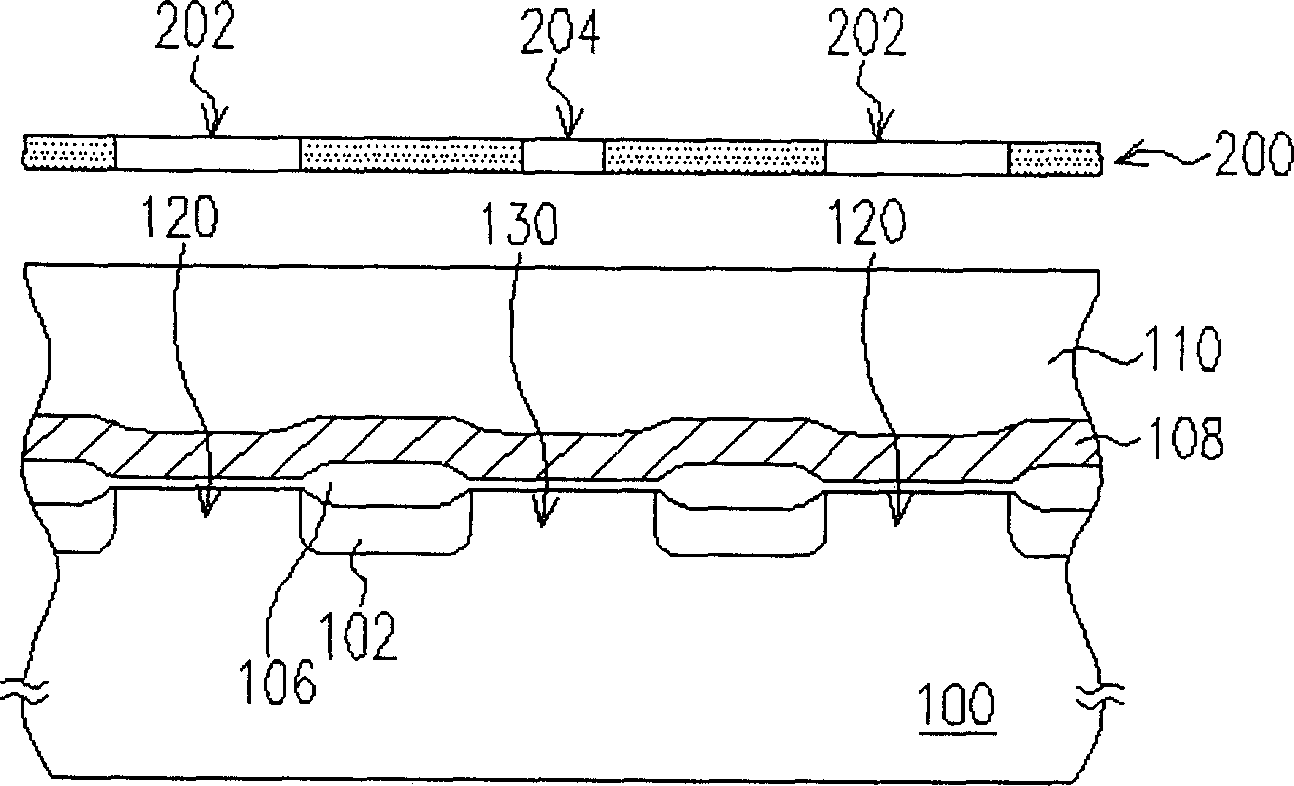

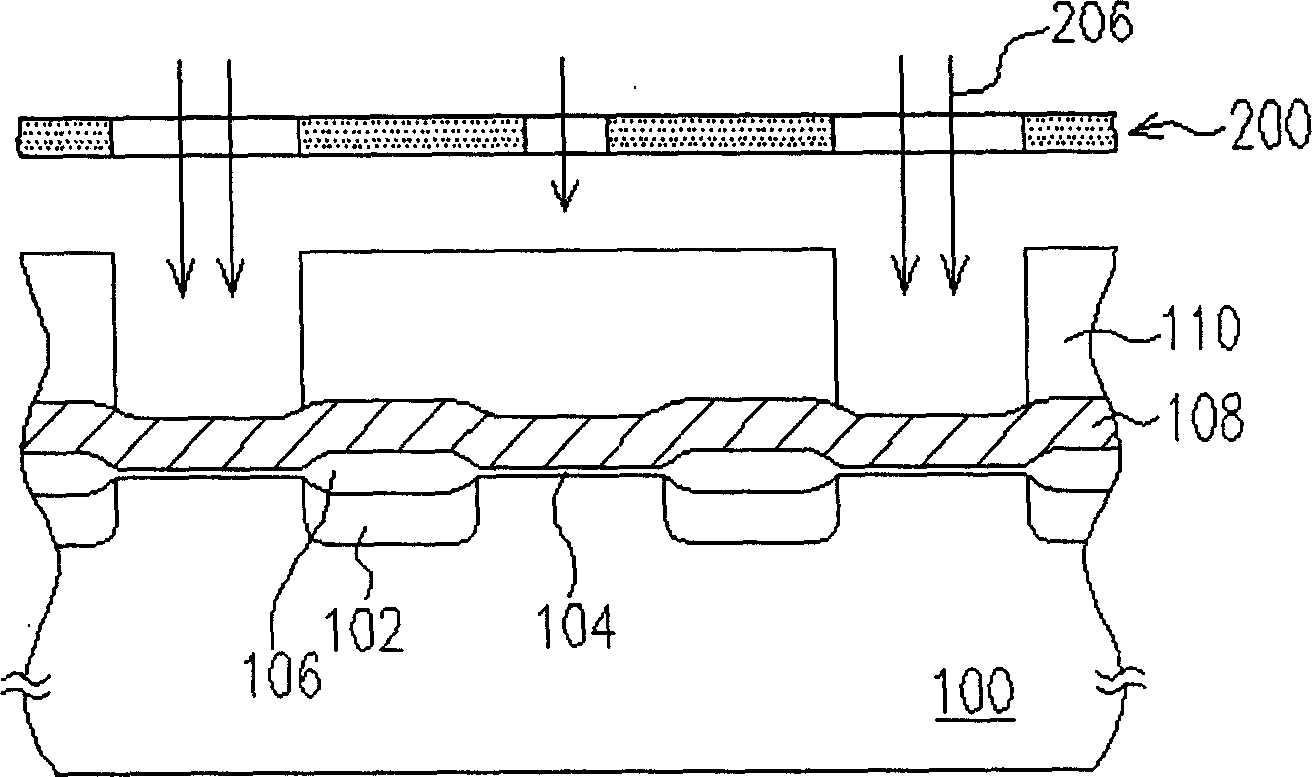

[0022] Figure 1A to Figure 1D As shown, it is a schematic cross-sectional flow diagram of the code implantation process of the mask-mode ROM according to a preferred embodiment of the present invention.

[0023] Please refer to Figure 1A , a mask mode read-only memory is composed of a plurality of memory cells arranged in a matrix, which includes a plurality of buried bit lines 102 disposed in the substrate 100, and a plurality of polysilicon word lines 108 across the bit lines 102 . The word line 108 is electrically isolated from the buried bit line 102 and the substrate 100 by an insulating structure 106 and a gate oxide layer 104 . Wherein, the region below the word line 108 and between two adjacent buried bit lines 102 is the channel region of the memory cell.

[0024] Next, a code implantation process is used to program the masked ROM. Its details are as follows.

[0025] Please refer to Figure 1B , forming a photoresist layer 110 on the substrate 100 to cover the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com