Joint device especially for sealing bag and method for filling and unfilling container insulated from environment

A docking device and environmental isolation technology, applied in the direction of closure, loading/unloading, packaging, etc., can solve problems such as inconvenient use, increased production cost of disposable items, and dislike of users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

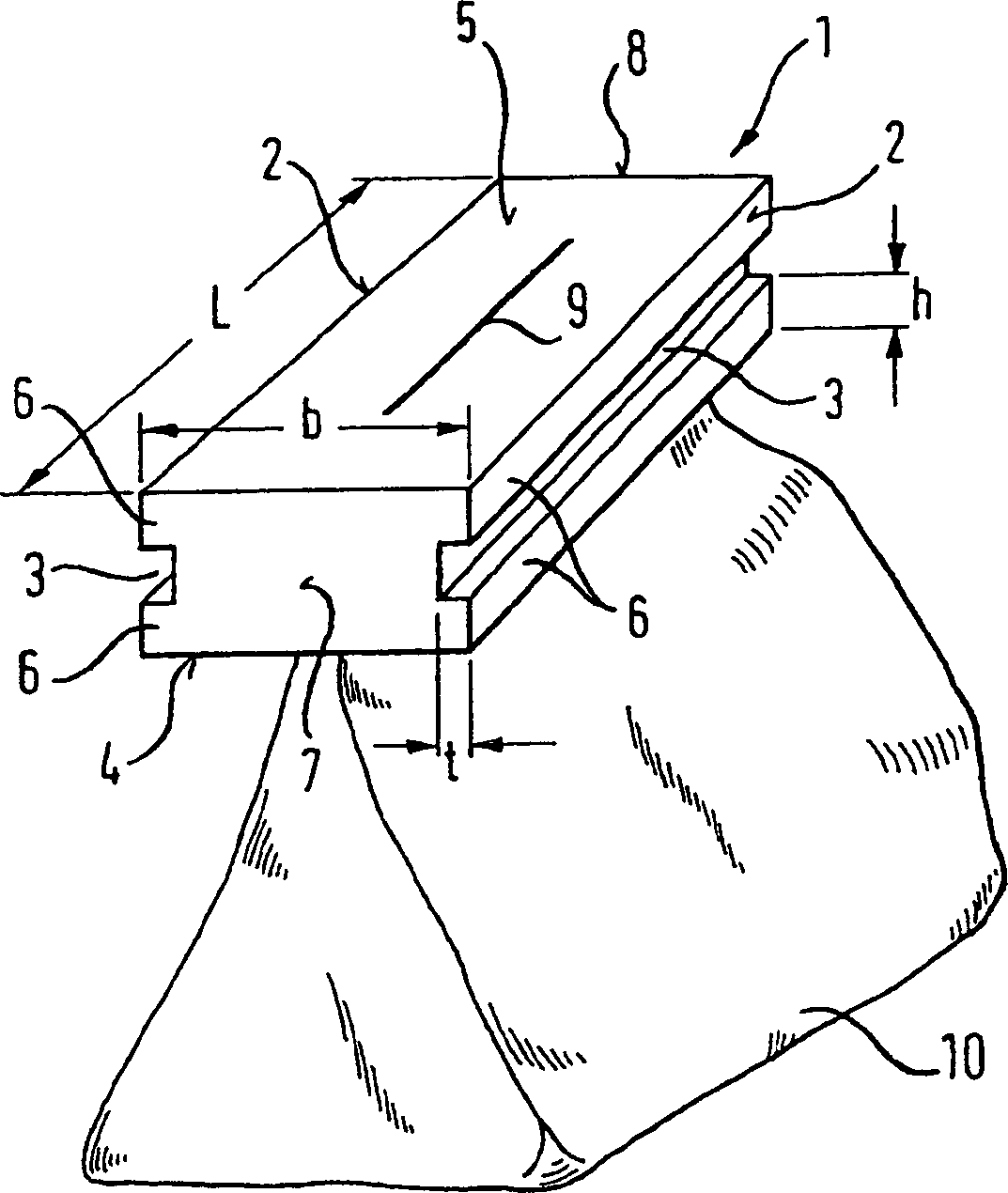

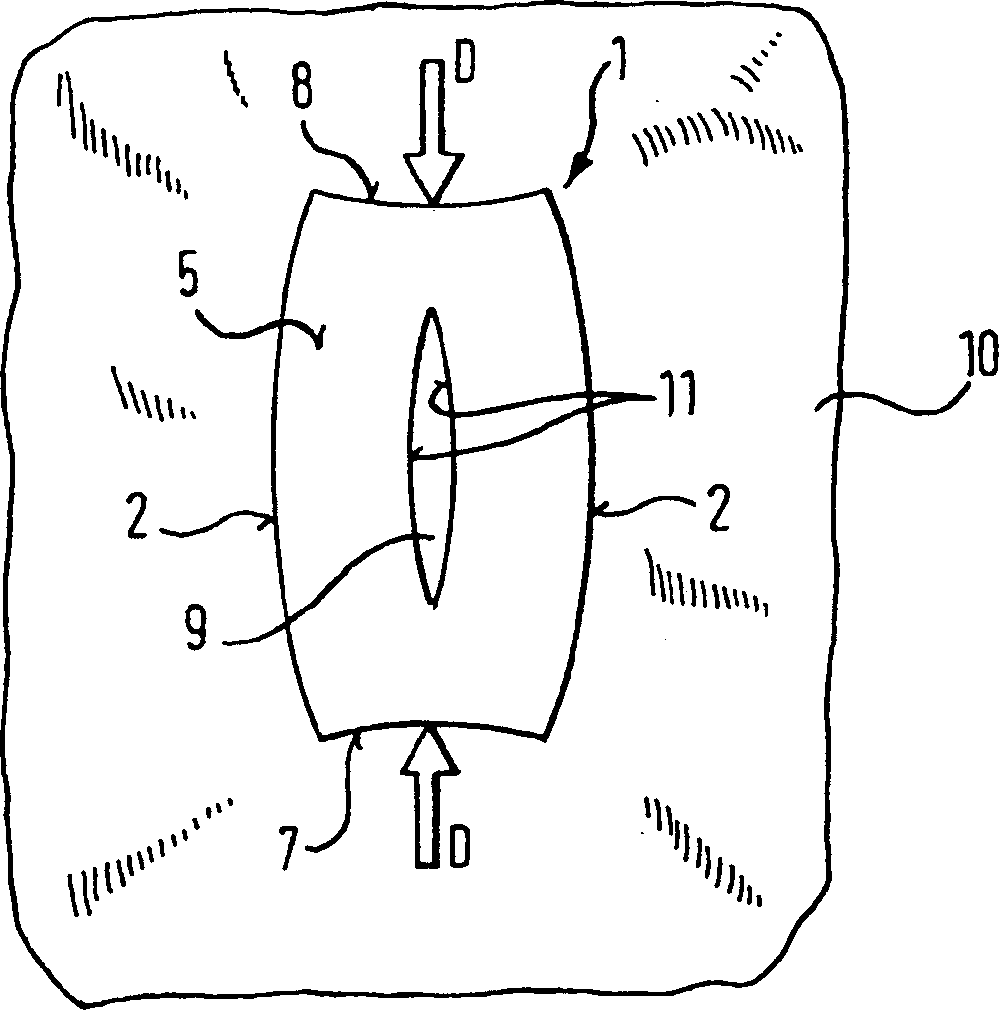

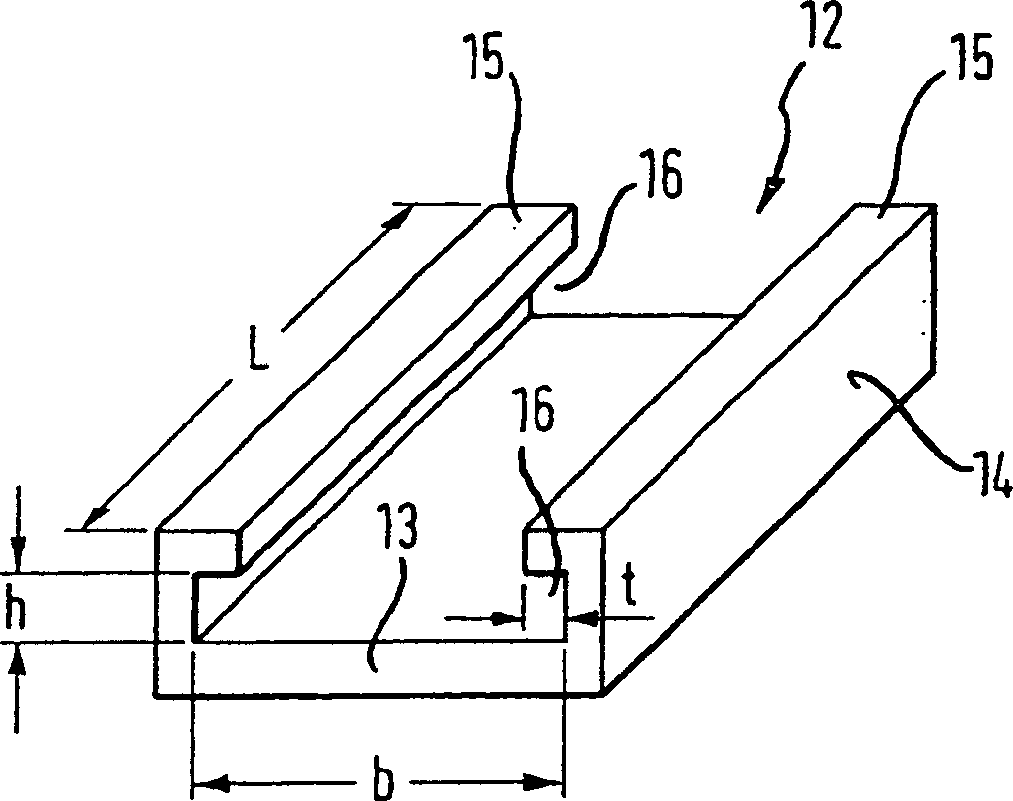

[0065] Depend on figure 1 It can be seen that the docking device according to the invention comprises a first coupling element 1 of side length L designed in the form of an elongated elastic body, which has a groove 3 of rectangular configuration on each of its sides 2 . The grooves 3 are arranged in the sides 2 in such a way that not only from the elastomer lower side 4 to the grooves 3 but also from the upper side 5 to the grooves 3, a crosspiece of height h and depth t is formed on each side 2 6, so that the front side 7 and the rear side 8 of the elastomer each have a maximum width b compared to their minimum dimension b-2t in the region of the groove 3. Centrally between the sides, a channel or slit 9 is machined in the elastomer, which is designed to pass through from the upper side 5 to the lower side 4 and to extend along a length that is less than the length L of the sides of the elastomer, preferably between 50 and 600 mm within range. A receptacle, for example in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com