Sinowilsonia henryi extract and its prepn process, composition and use

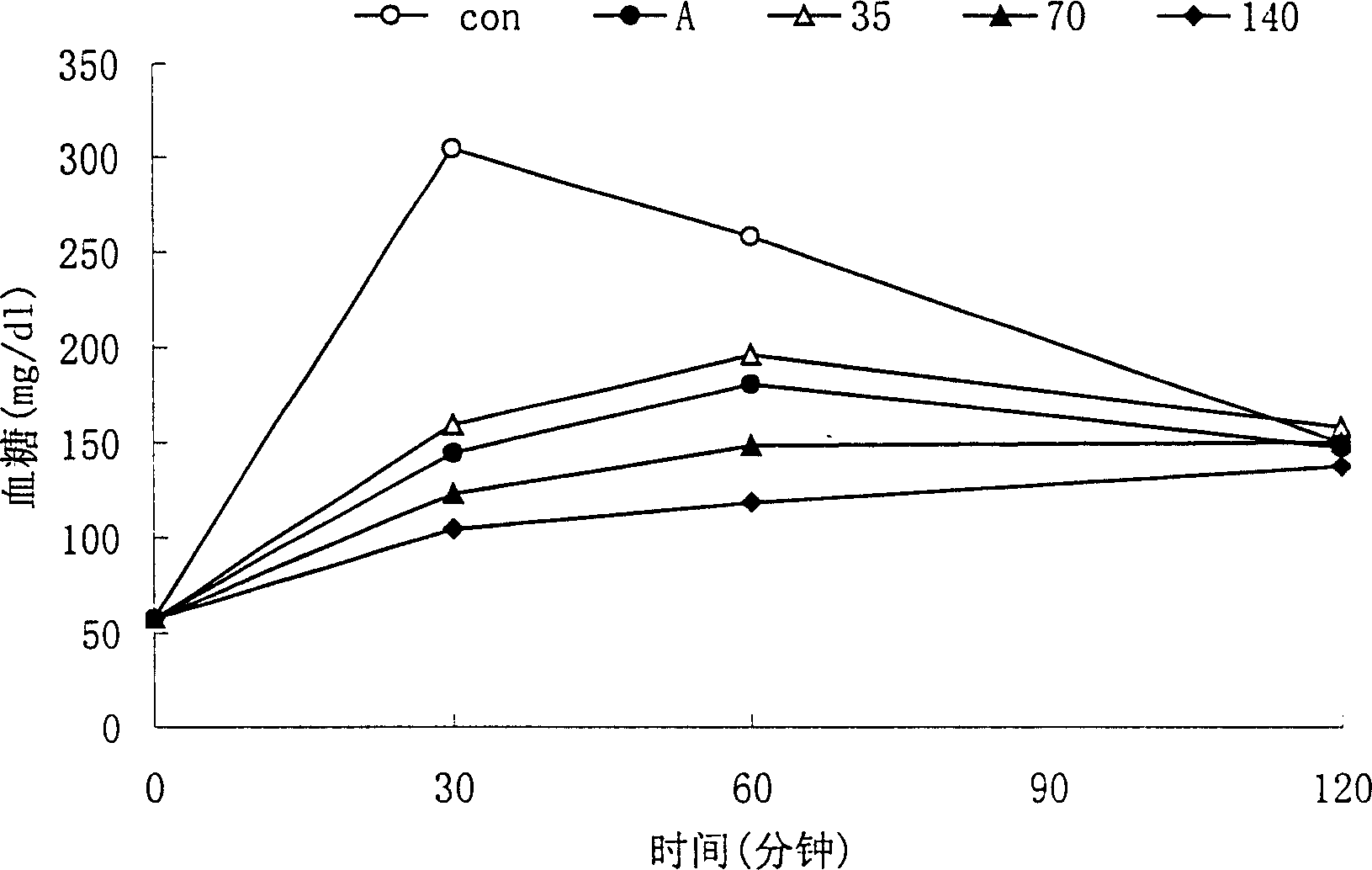

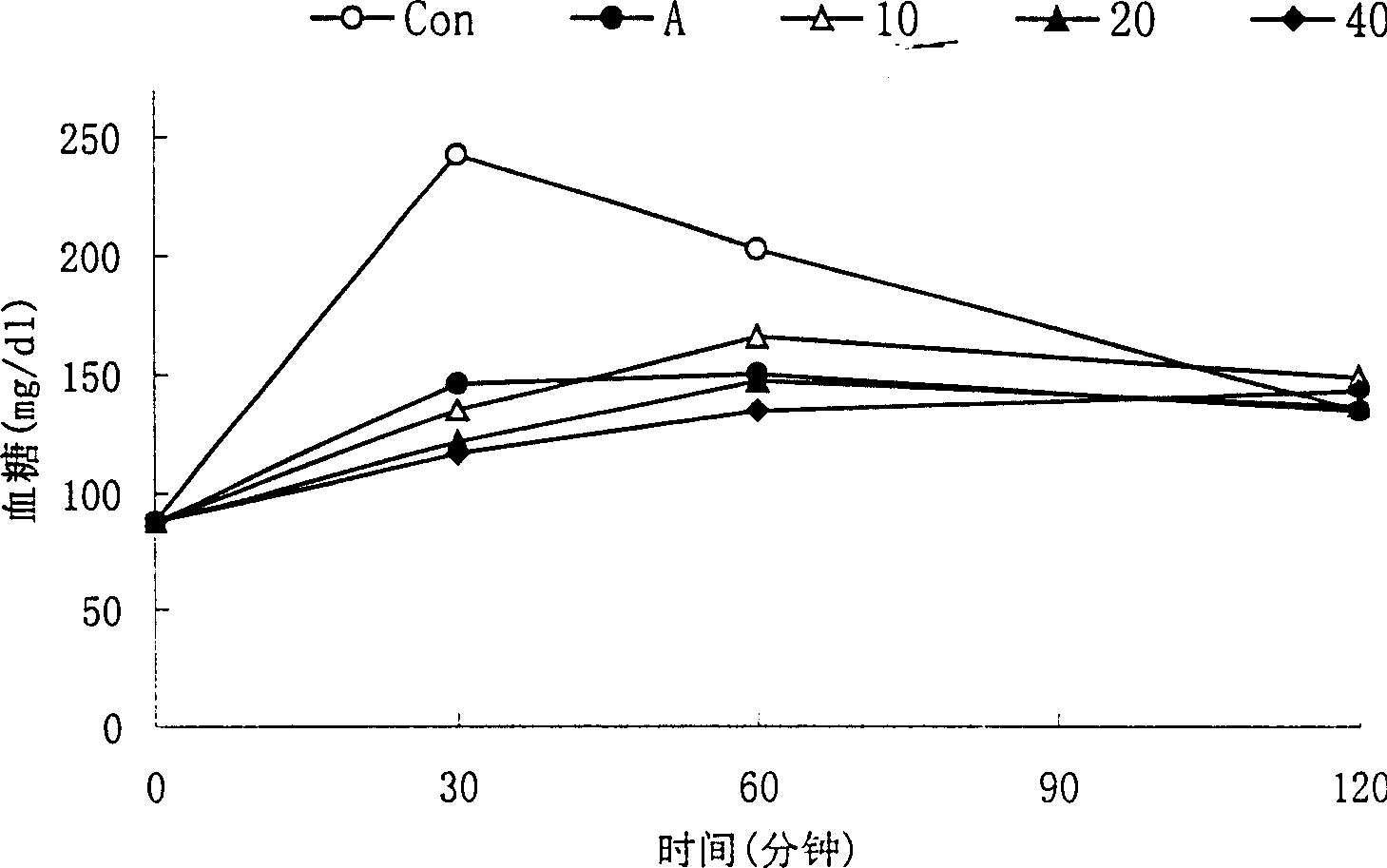

An extraction method and extract technology are applied in the application field of preparing medicines for treating hyperglycemia and obesity, and achieve the effects of reducing the area under the blood sugar curve, inhibiting the rise of blood sugar, and delaying digestion and absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1. water extraction extract

[0044] Radix 100g, heat reflux with 500g of distilled water, extract three times (500g water / time), extract one hour at every turn, obtain water extract 15.5g after extracting liquid concentrating under reduced pressure. Dissolve 15.5 g of the extract in 100 ml of water, add ethanol to contain 70% alcohol (volume ratio), precipitate, filter, and concentrate the filtrate to dryness to obtain 13.6 g of a yellow paste.

[0045] Separation of the filtrate on a macroporous resin column:

[0046] 13.6 g of the filtrate was dissolved in 50 ml of water, added to a 100 g macroporous resin column (D-101), washed with distilled water until the effluent was colorless, and the distilled water eluate was concentrated to dryness to obtain 11 g of eluate.

[0047] The macroporous resin was then eluted with ethanol until the effluent was colorless, and the ethanol-eluted part was concentrated to obtain 2.2 g. The macroporous resin is washed wit...

Embodiment 2

[0050] Embodiment 2. water extraction extract

[0051] 1 kilogram of Radix Twig is extracted under reflux with 14 kilograms of distilled water, extracted three times (14 kilograms of water / time), and extracted for one hour each time, and the extract was concentrated under reduced pressure to obtain 155 g of water extract. 155 g of the extract was dissolved in 1550 ml of water, and ethanol was added to contain 70% alcohol (volume ratio), precipitated, filtered, and the filtrate was concentrated to dryness to obtain 136 g of a yellow paste.

[0052] Separation of the filtrate on a macroporous resin column:

[0053] 136 g of the filtrate was dissolved in 500 ml of water, added to a 1000 g macroporous resin column (D-101), washed with distilled water until the effluent was colorless, and the distilled water eluate was concentrated to dryness to obtain 110 g of eluate.

[0054] The macroporous resin was then eluted with ethanol until the effluent was colorless, and the ethanol elu...

Embodiment 3

[0057] Embodiment 3. Alcoholic extract

[0058] Add 1 kg of white tree bark, add 6 times the amount of 70% (volume ratio) ethanol, soak overnight or 4 hours, slowly heat to boiling, reflux for 1 hour, filter; repeat the whole process twice, combine the filtrate, concentrate under reduced pressure, temperature 60- 70°C, pressure 85-98KPa, when concentrated to completely free of ethanol, add 1 kg of water and continue to heat until boiling, after cooling, centrifuge to remove insoluble matter, and add a small amount of water to wash the insoluble matter three times, combine the filtrates, and reduce at a temperature of 60-70°C Concentrate under reduced pressure, and then dry under reduced pressure (temperature 70-80°C, pressure 85-98Kpa) to obtain 106g of extract.

[0059] Pharmacological experiment

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com