Friction clutch with predamper

A technology of transmission disc and clutch, applied in the direction of clutch, friction clutch, mechanical drive clutch, etc., can solve the problem of expensive tools and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

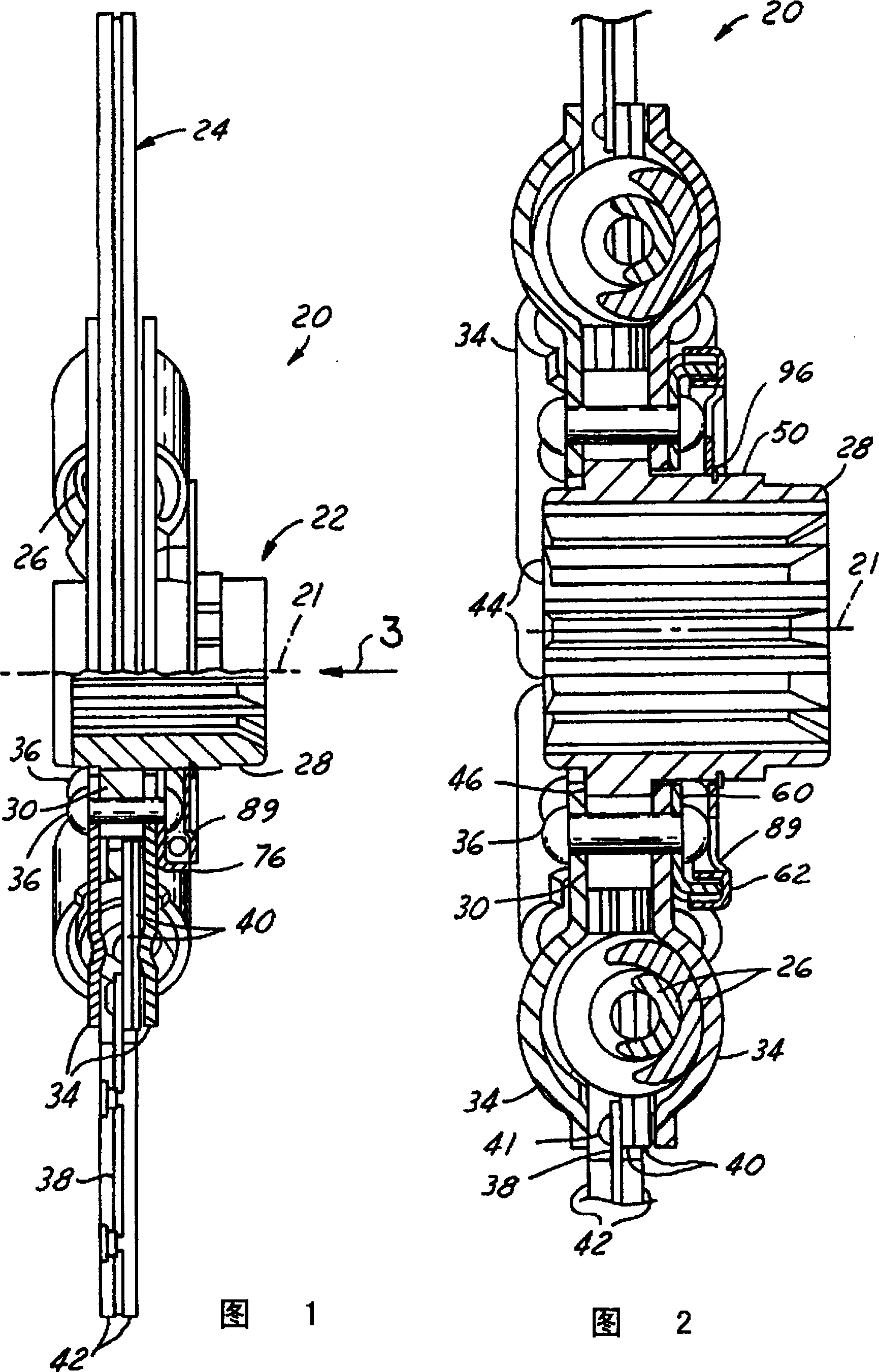

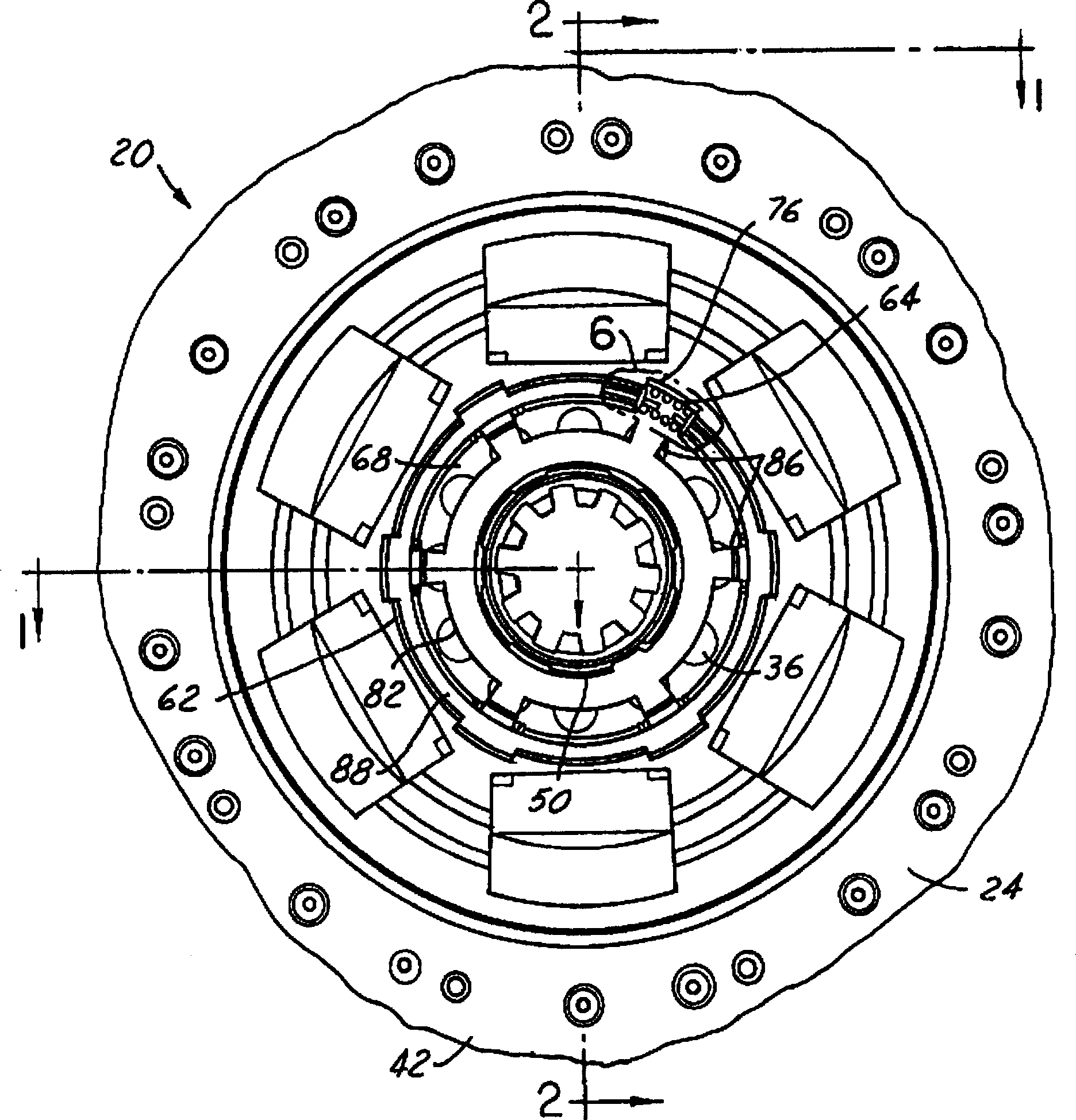

[0016] The clutch drive disc assembly 20 shown in Figure 1 includes a rotation axis 21, a sliding sleeve assembly 22, a disc assembly 24 and a number of damping or transmission springs 26, which are arranged between the sliding sleeve assembly 22 and the disc assembly 24 .

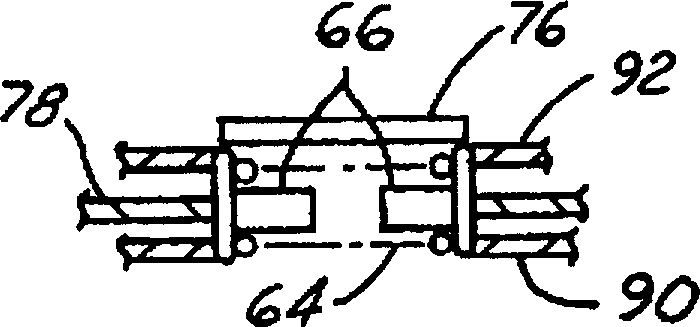

[0017] As best shown in FIGS. 2 and 4, the sliding sleeve assembly 22 includes an inner sliding sleeve 28 and an outer sliding sleeve 30. The pre-damper 32 is arranged between the inner sliding sleeve 28 and the outer sliding sleeve 30. A pair of spring plates 34 are fixed on the outer sliding sleeve 30 by rivets 36.

[0018] The disc assembly 24 includes an annular disc 38 which is fixed on a pair of overlapping annular stacks 40 by rivets 41. The stack 40 is radially arranged inside the disk 38. Opposing materials 42 are placed on each side of the disc 38 so that when it is installed in a vehicle, it frictionally engages with a clutch flywheel (not shown) and a clutch pressure plate (not shown). The stack 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com