Rotating disc type packaging machine

A packaging machine and turntable technology, which is applied in packaging, transportation packaging, transportation and packaging, etc., can solve problems such as difficult flexible production, and achieve the effects of shortening the production cycle, maximizing space utilization, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further illustrate the present invention below in conjunction with accompanying drawing.

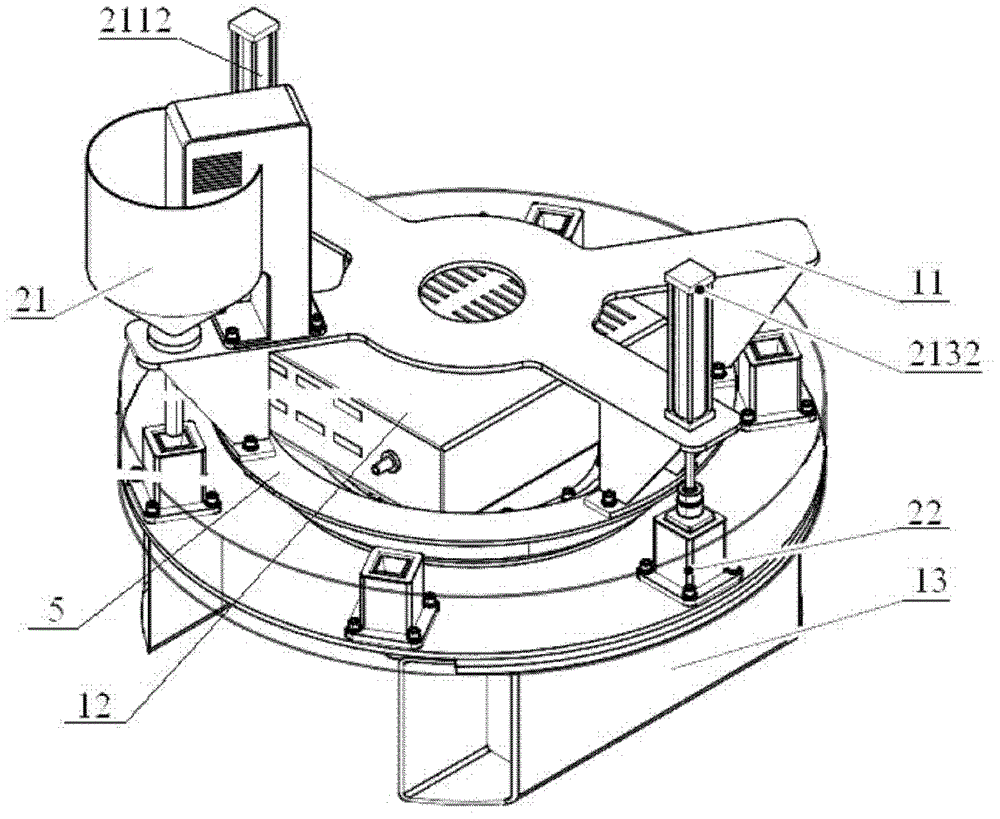

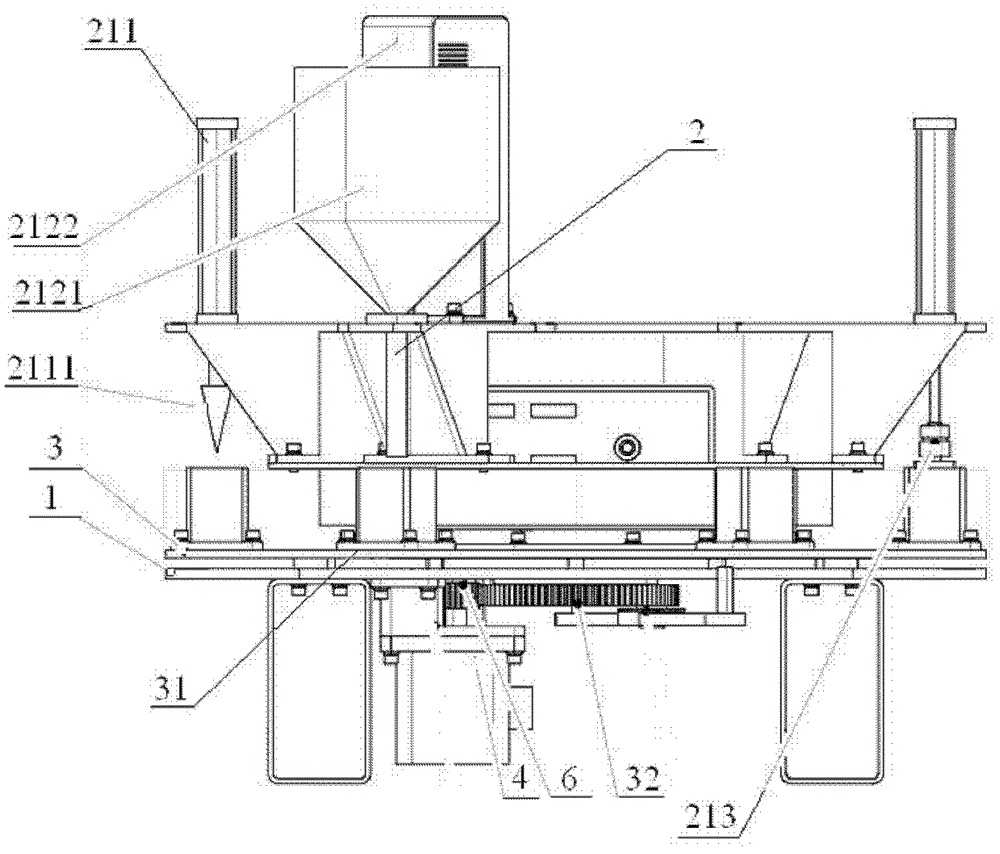

[0019] Referring to the attached picture:

[0020] The turntable packaging machine of the present invention includes a work surface, and the work surface includes a base 1, a station 2, a turntable mechanism 3, a motor 4, a motor box 5 and a gear 6, and the frame is installed on the base 1 11. Support base 12, support feet 13, the stations 2 are distributed along the circumference of the worktable, and each station 2 is provided with a corresponding working machine 21 and a lower mold 22, and the working machine 21 is installed on On the frame 11; the turntable mechanism 3 is driven by the motor 4 through the gear 6, and the working machine 21 and the motor 4 are all connected to the power supply box 5;

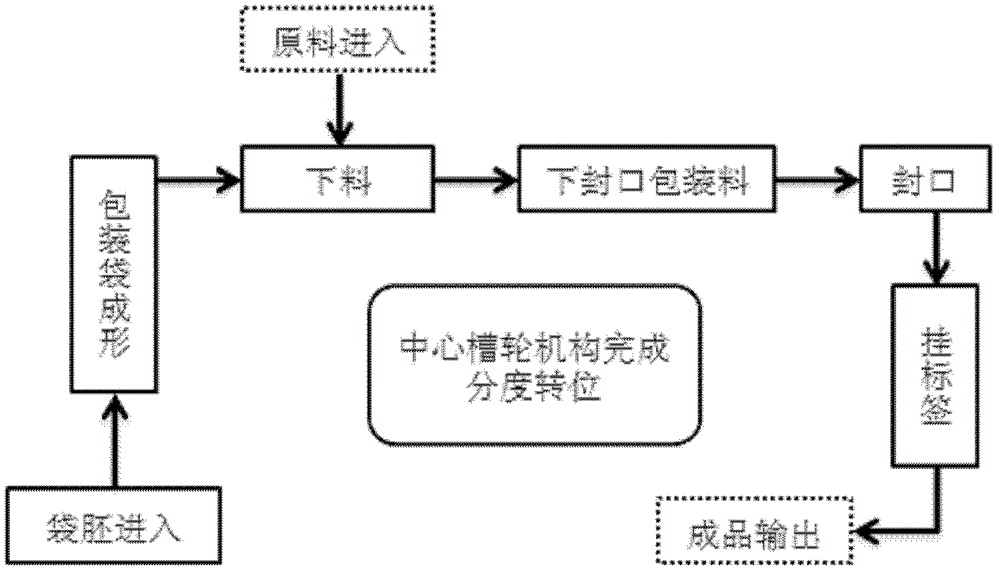

[0021] The station 2 is followed by adding bag embryo station 23, packaging bag forming station 24, blanking station 25, lower sealing packaging material station 26, sealing sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com