Method for creating ultra-clean mini-environment through localized air flow augentation

A transmission channel and particle technology, applied in transportation and packaging, conveyor objects, thin material handling, etc., can solve problems such as cost reduction, qualified rate, and two-chamber contamination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The invention is used for providing a local ultra-clean microenvironment during wafer processing. In terms used herein, wafer and substrate are interchangeable. Preferably, the mini-environment is configured to include a purge gas flow regime in the vicinity of the particle generation device to purge particles from the wafer or wafer transport path. It will be apparent, however, to one skilled in the art that the present invention may be practiced without some or all of these specific details. In addition, well known process operations have not been described in detail in order not to obscure the present invention.

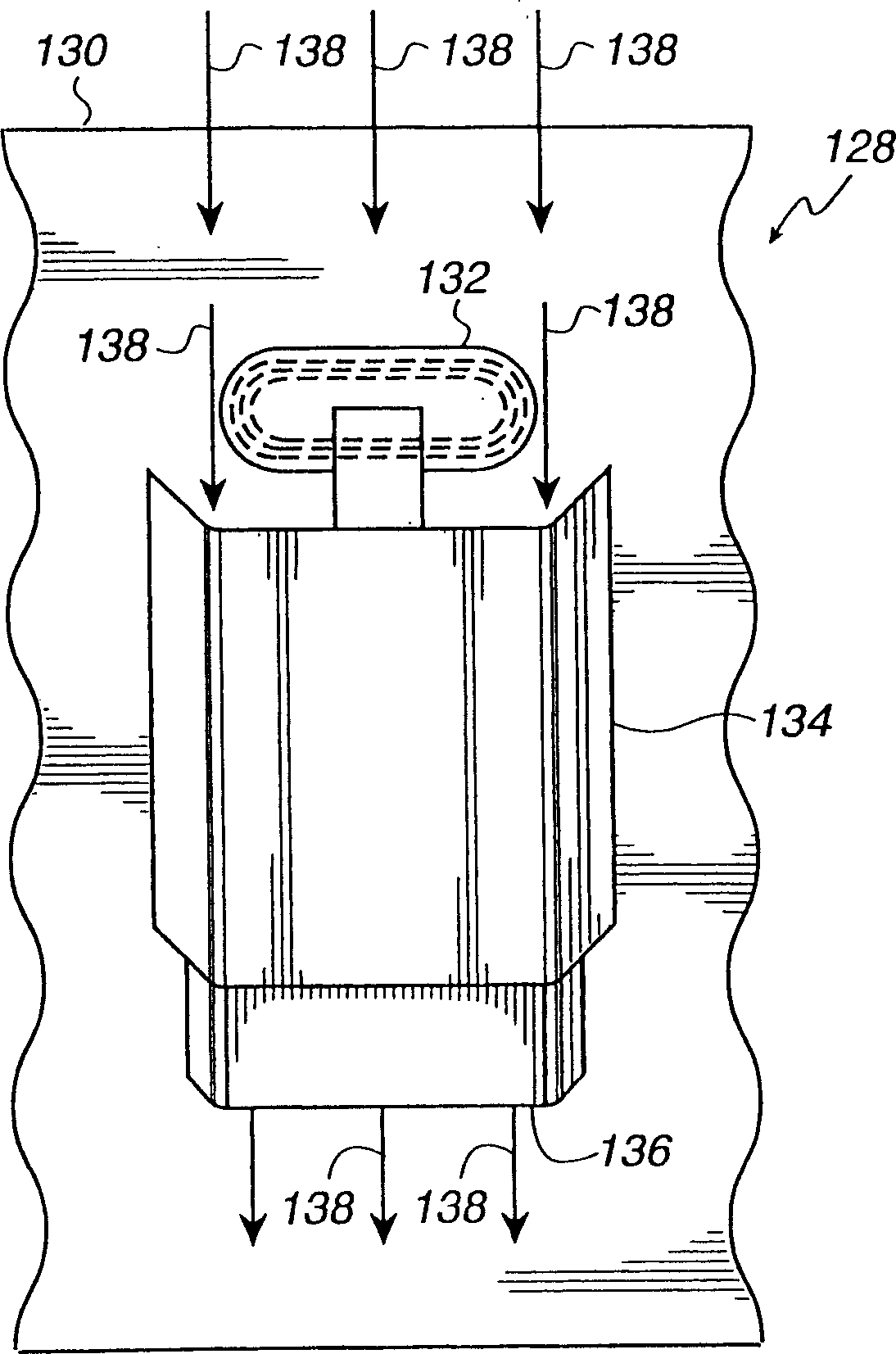

[0030] figure 2 A transfer channel with localized airflow enhancement according to one embodiment of the present invention is shown schematically at 128 . In schematic view 128, chamber wall 130 contains an aperture covered by slit valve 132 shown in the closed position. It will be appreciated that the slot valve 132 in the closed position isolates the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com