Combine combing barrel

A technology for combine harvesters and sealing cylinders, applied to harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of large seed splash loss and poor adaptability on both sides of the cutting width, reduce seed splash loss, overcome leakage Effect of combing and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

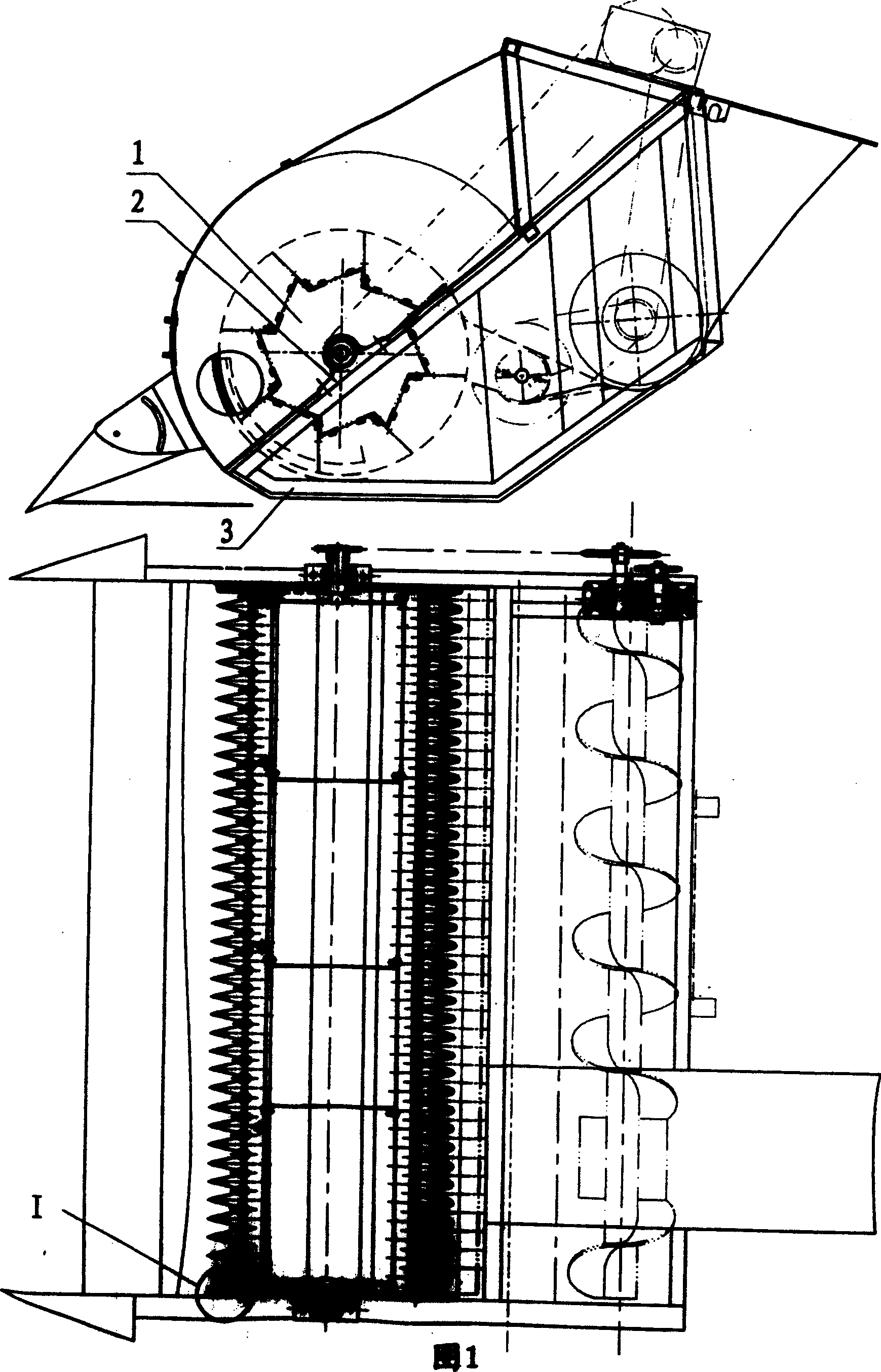

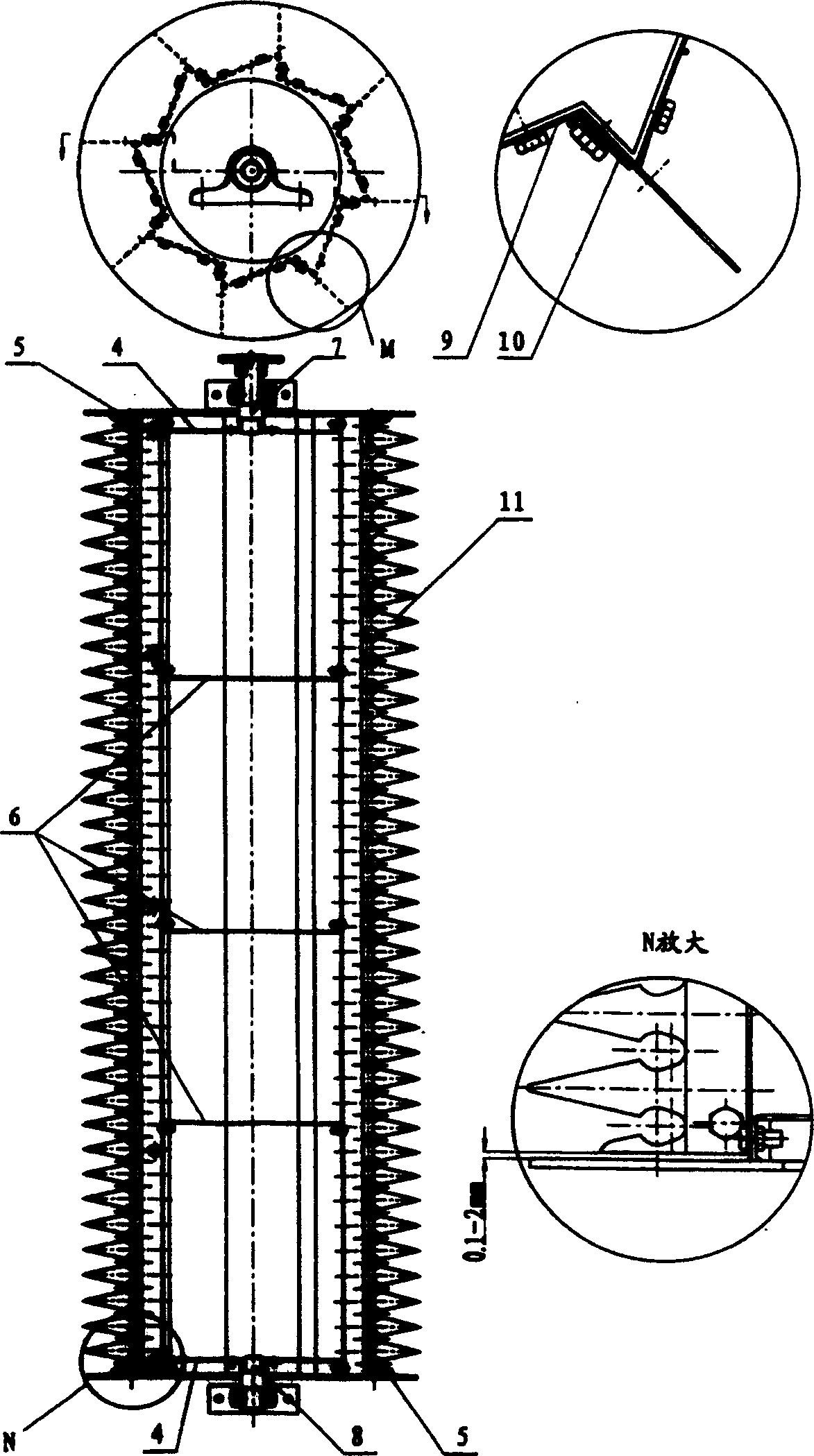

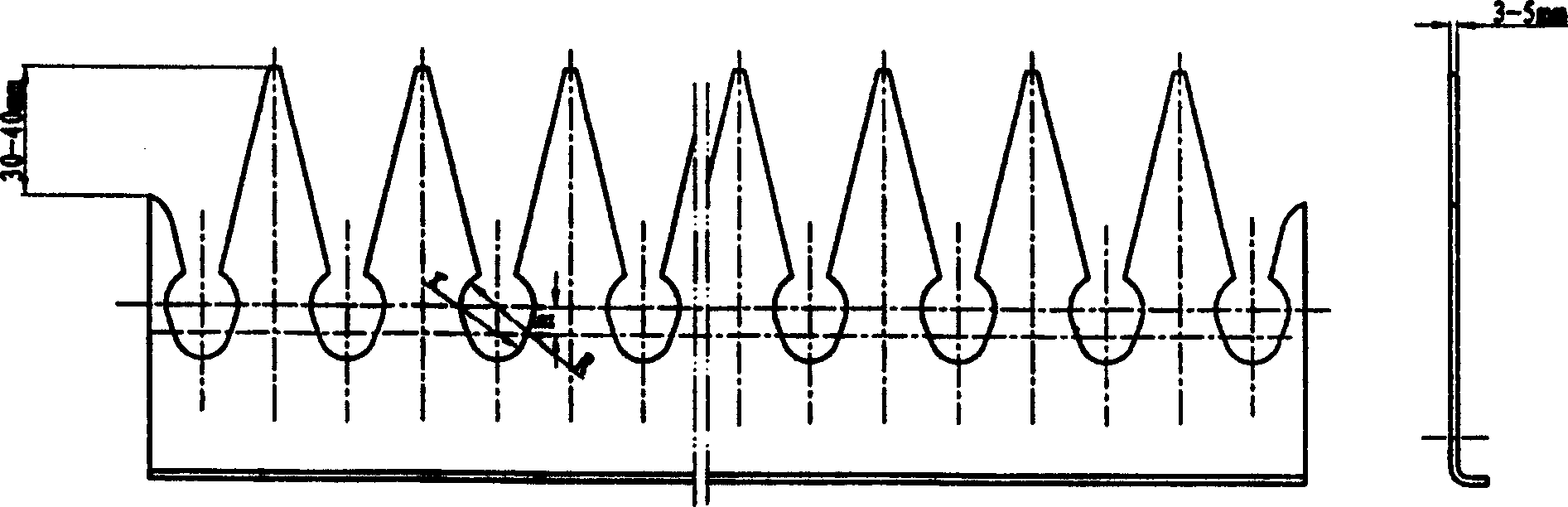

[0012] According to Figure 1, figure 2 and image 3 As shown, the present invention mainly consists of 2 discs 4, 3 intermediate discs 6, 8 comb tooth plates 11, 8 tooth plate fixing plates 10, 8 sealing plates 9, input shaft combination 7, and support shaft combination 8 composition. The comb tooth plate is punched by 3-5mm steel plate. The tooth shape of the comb tooth plate 11 is triangular, and the front portion is a heart-shaped comb cavity formed by two semicircles of different sizes and a trapezoid between adjacent two teeth. The comb teeth at both ends have a half-tooth structure, and the height of the half-tooth is 30-40mm smaller than that of the full-tooth. The comb tooth plate 11 and the tooth plate fixing plate 10 are connected to the disc 4 and the middle disc 6 by bolts, and the outer end surface of the disc 4 is welded with a circular baffle 5, and the baffle 5 and the comb tooth plate 11 are connected together. The gap in the axial direction is 0.1-2mm. Tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com