Patents

Literature

34results about How to "Reduce splash loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

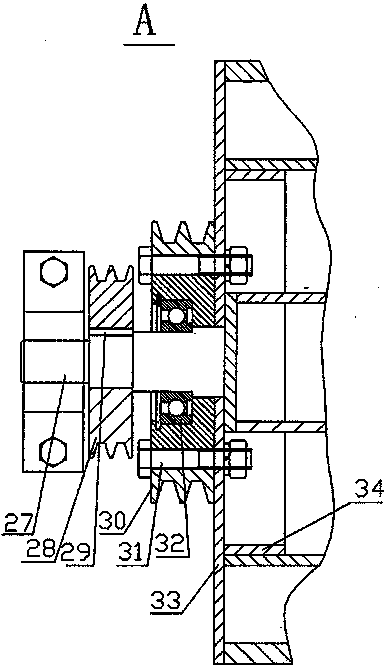

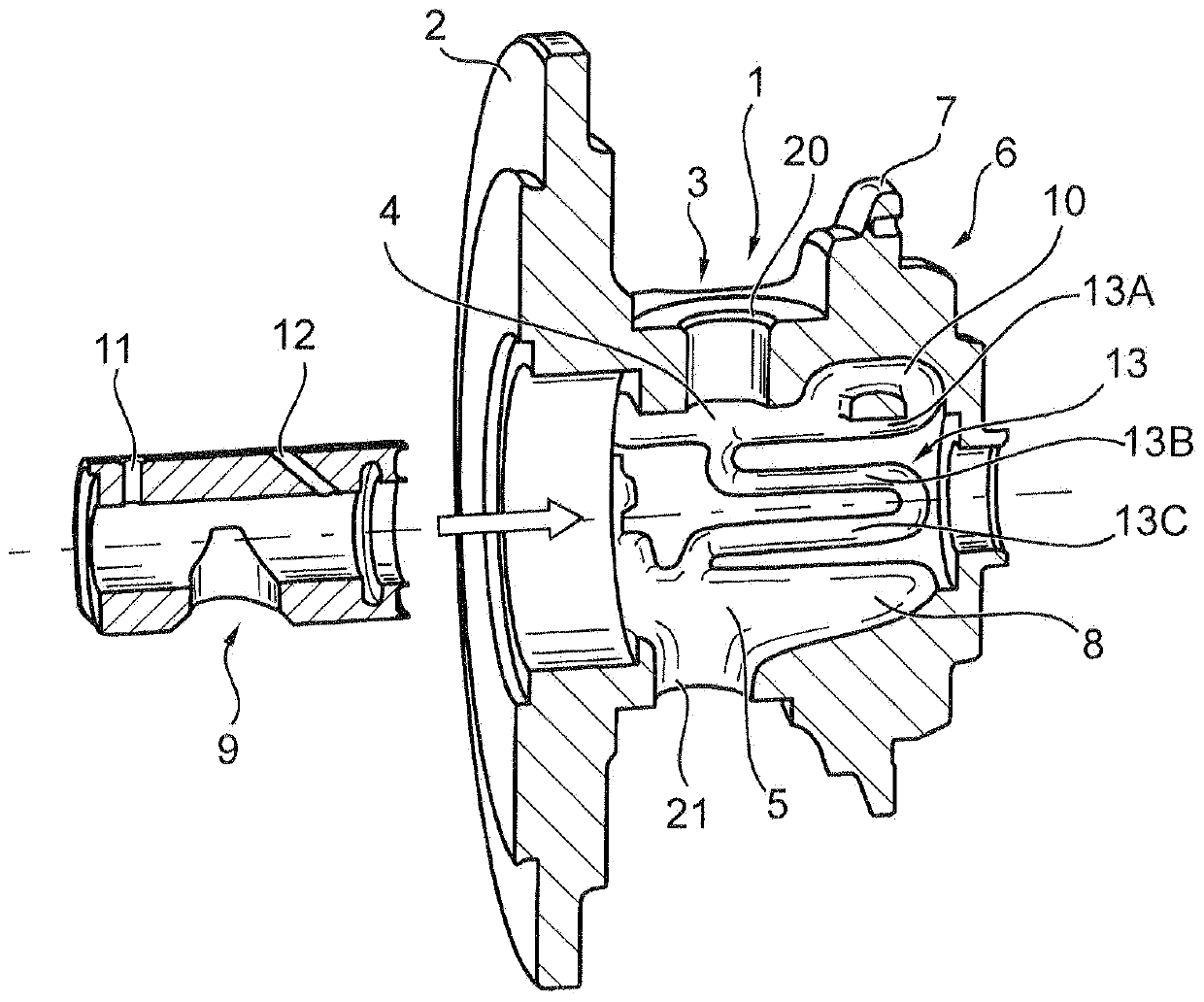

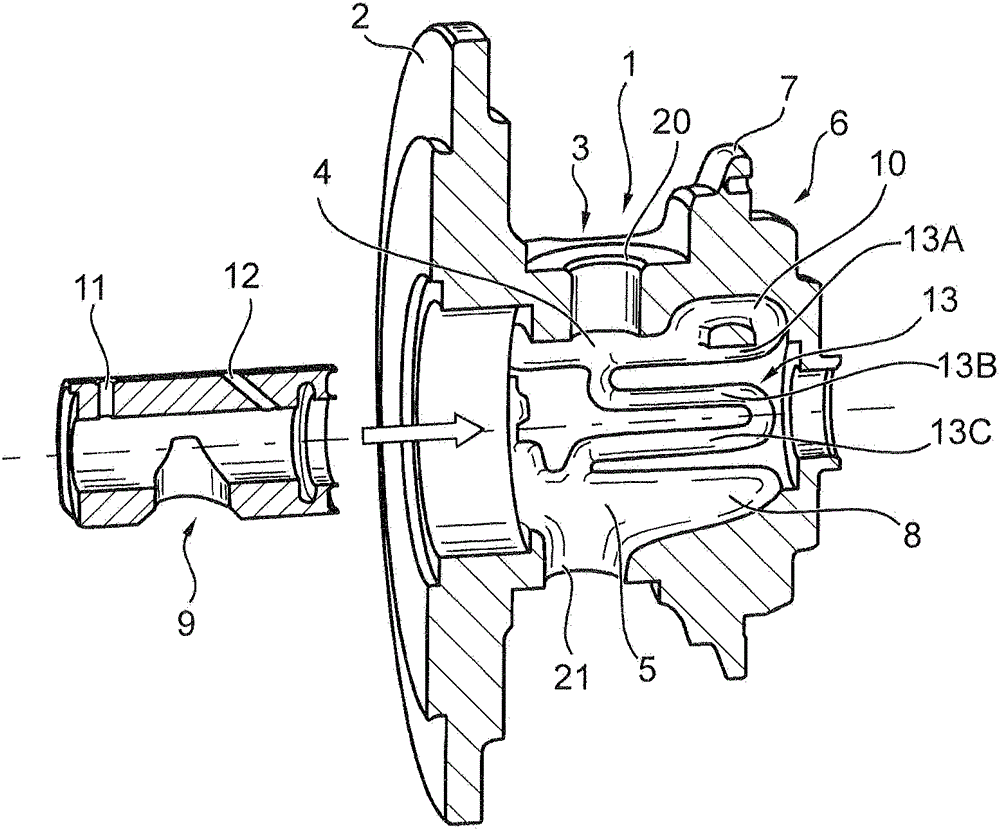

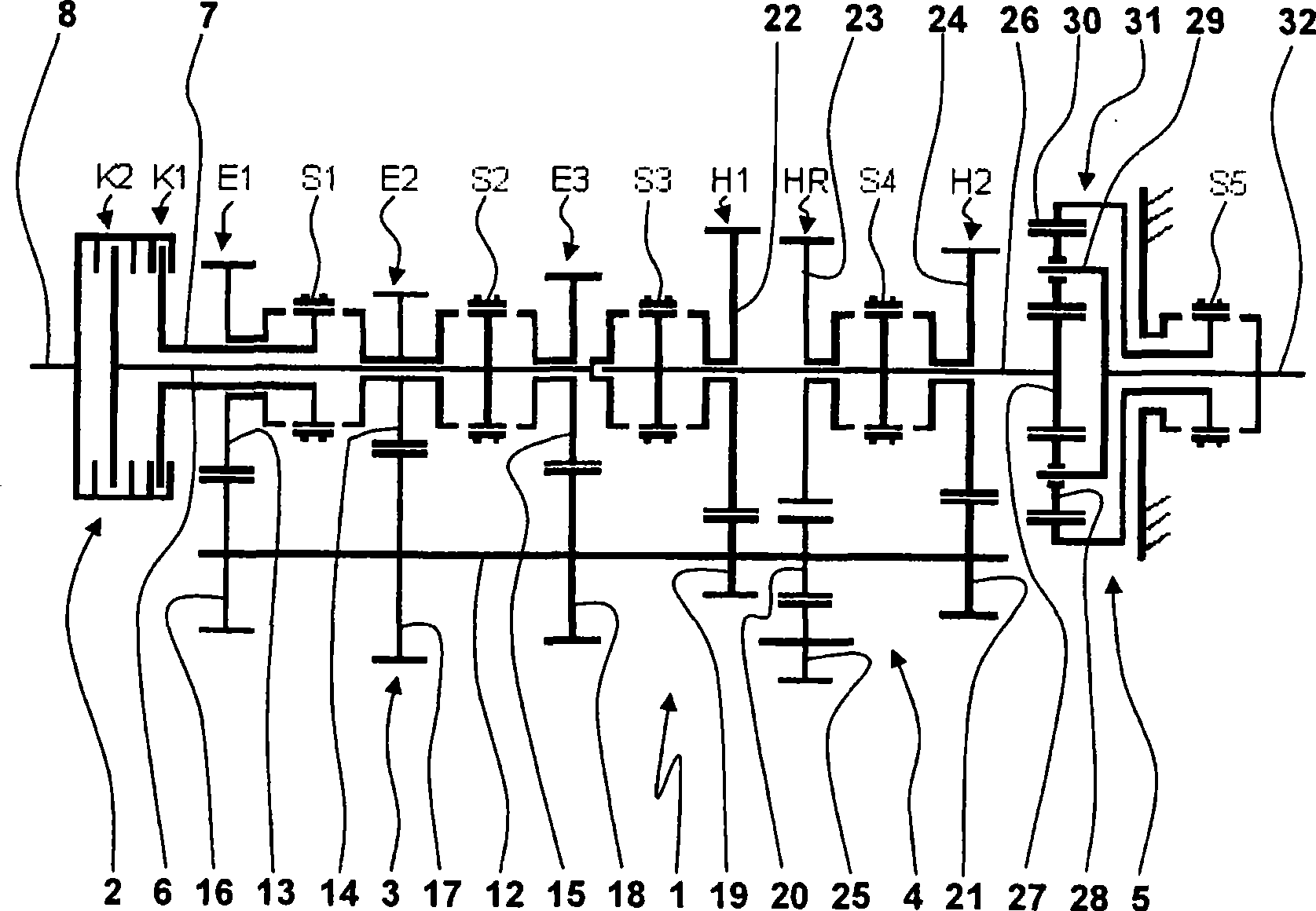

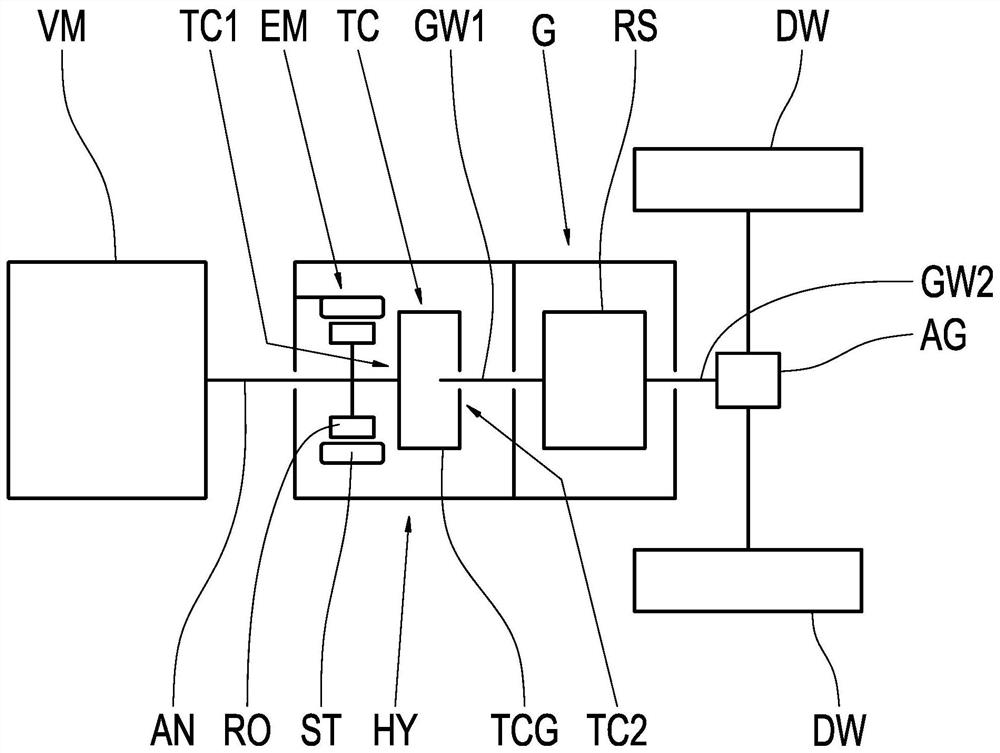

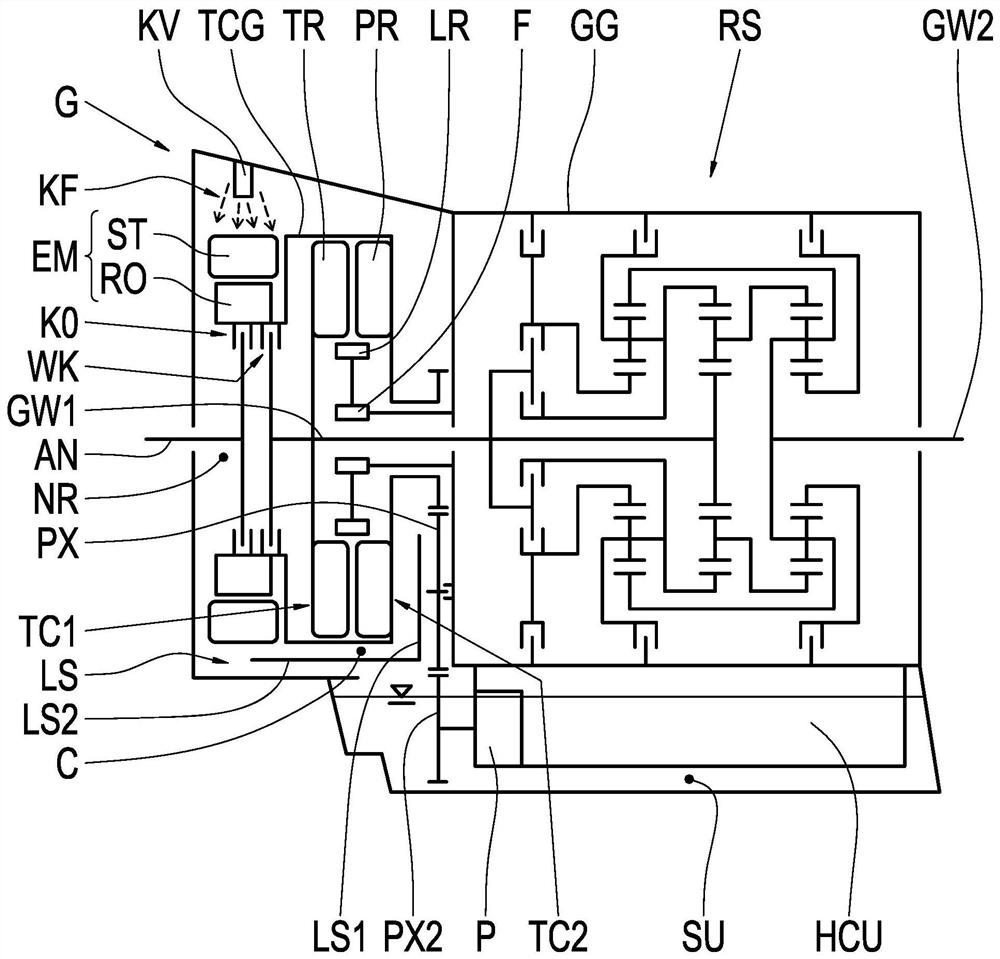

Power-shift transmission for a commercial vehicle

InactiveCN101415967ALarge installation spaceSave installation spaceToothed gearingsTransmission elementsPower flowEngineering

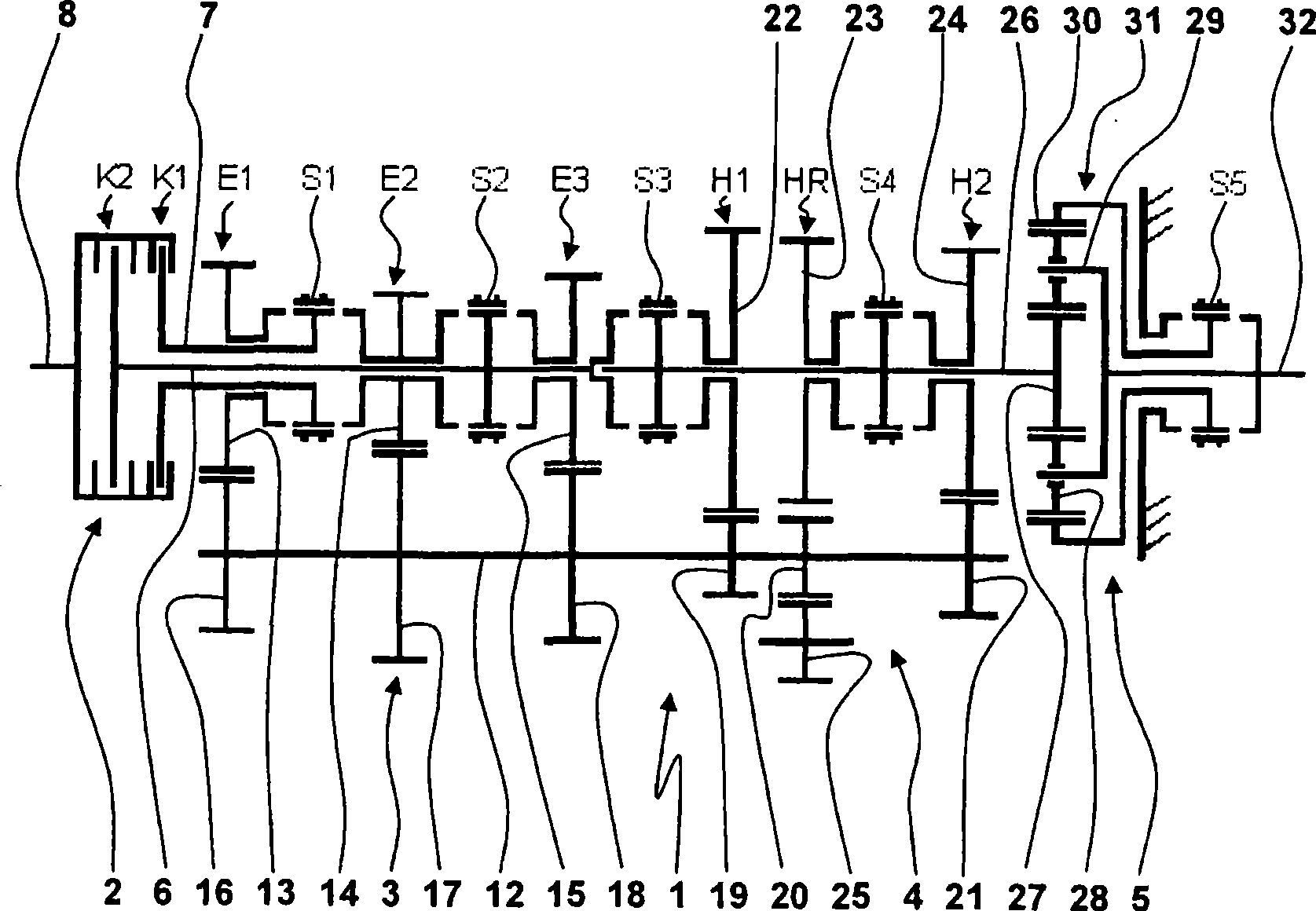

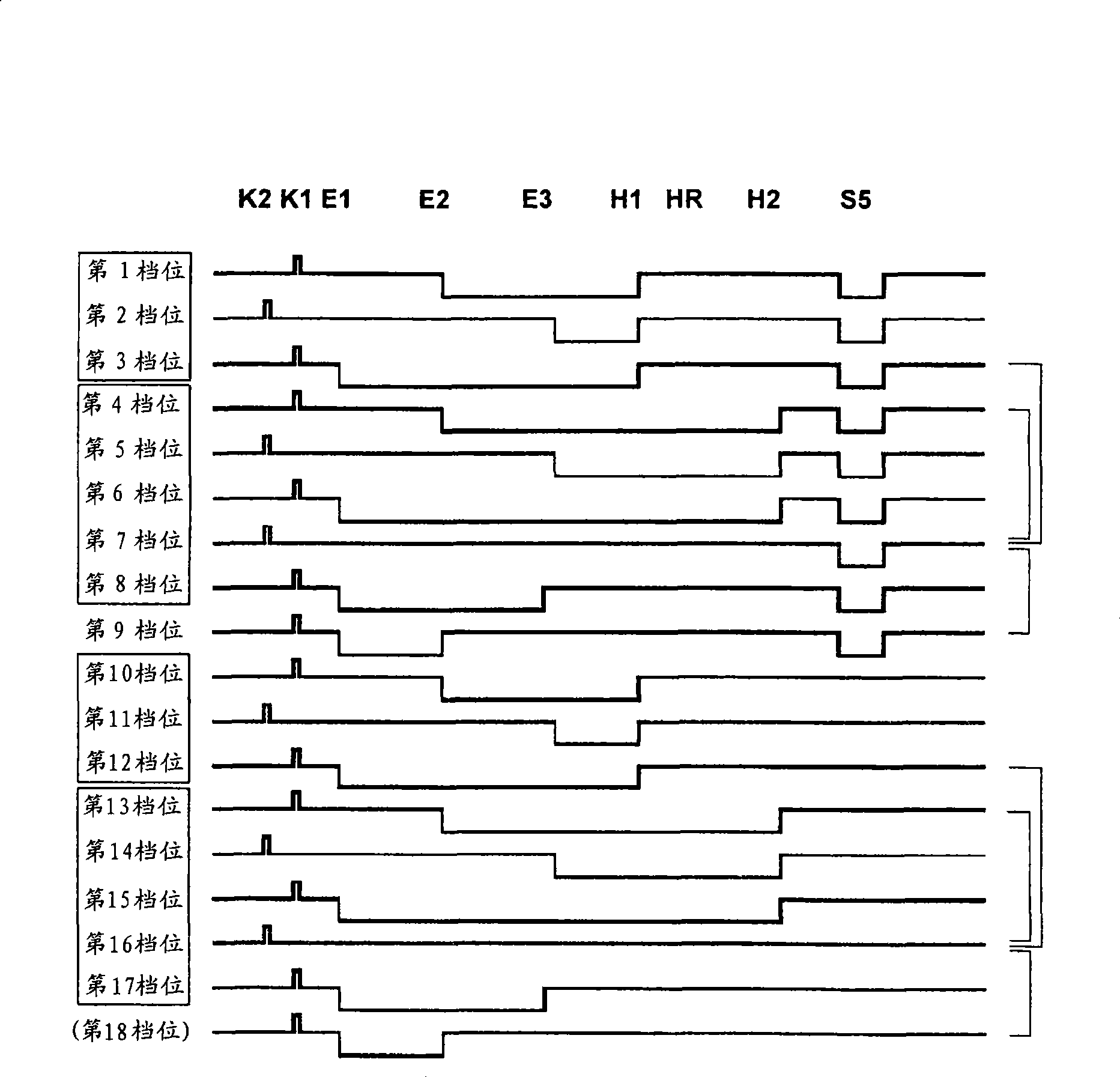

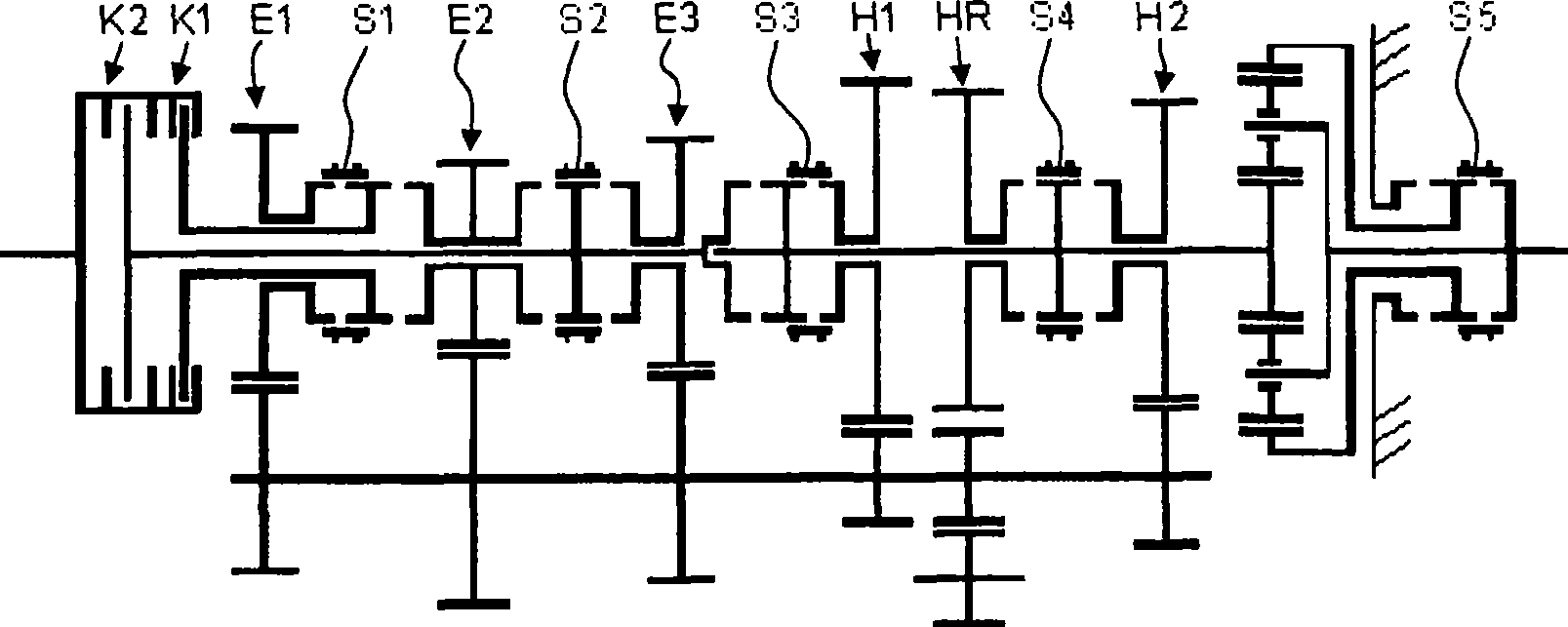

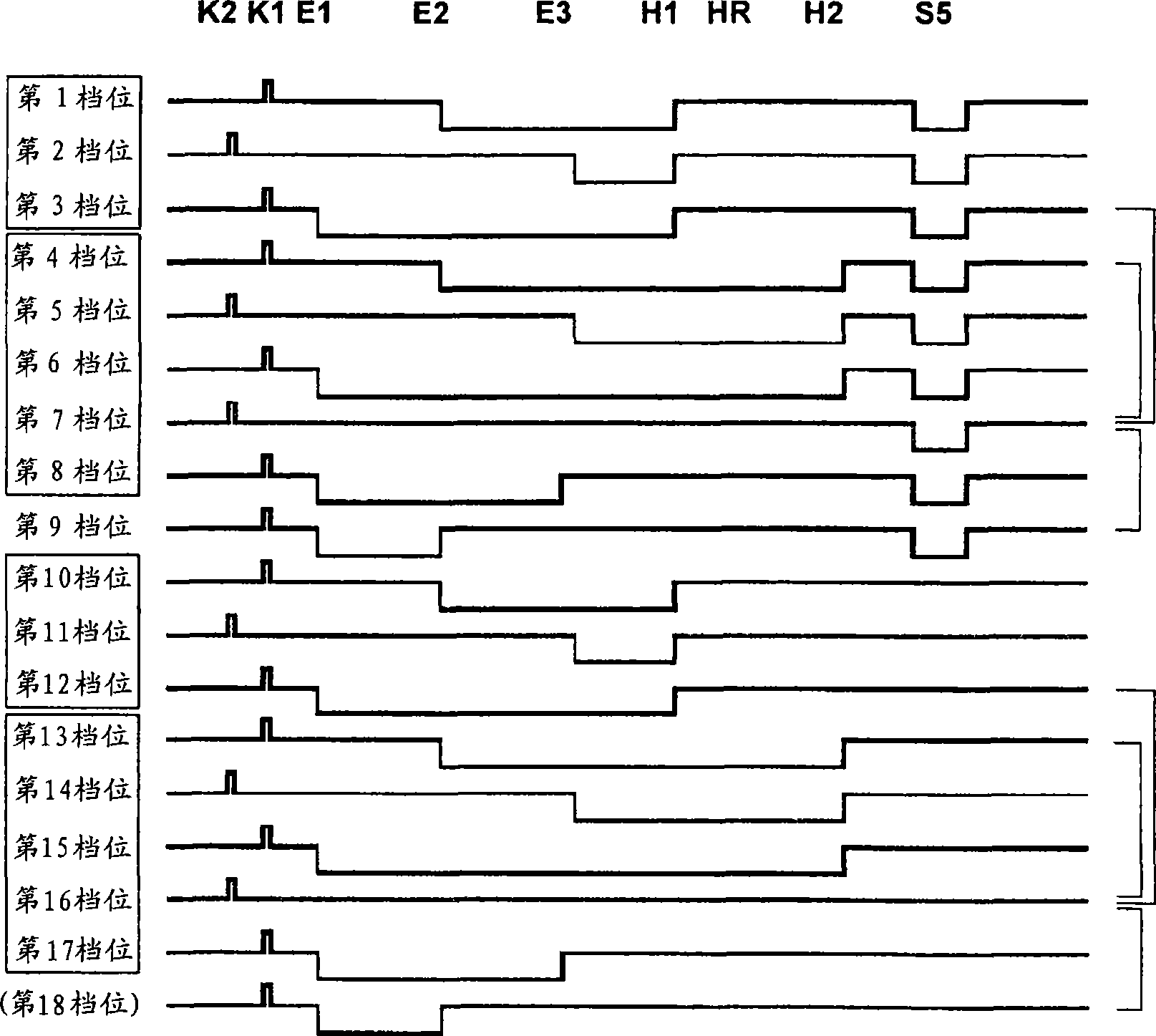

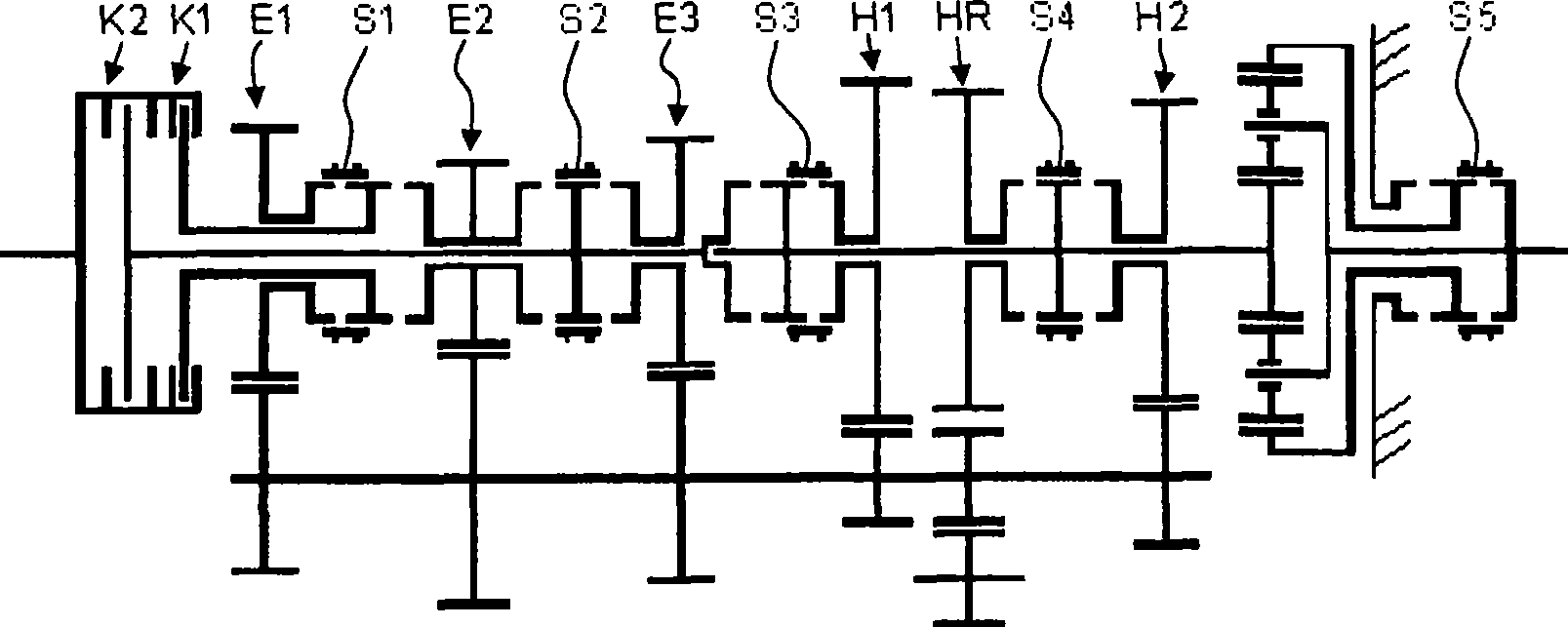

The invention relates to a power-shift transmission for a commercial vehicle having a split group (3), a main group (4) and a range group (5). According to the invention, it is possible to connect a loose wheel (14) of an input constant (E2) fixedly in terms of rotation, optionally via the shifting elements (S1) and (S2), to two input shafts (6, 7) which can be coupled in each case via clutches (K1, K2) to a transmission input shaft (8). An idler shaft (12) can be driven via three input constants (E1, E2, E3), wherein a power flow takes place via the idler shaft (12) in all forward gears with the exception of a direct gear. With a simple construction, the design according to the invention results in the possibility of sequential gearshifts without interruptions in traction forces and multiple-gear upshifts and multiple-gear downshifts.

Owner:DAIMLER AG

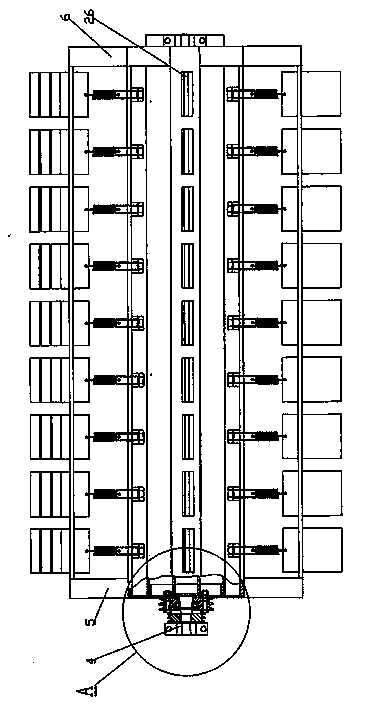

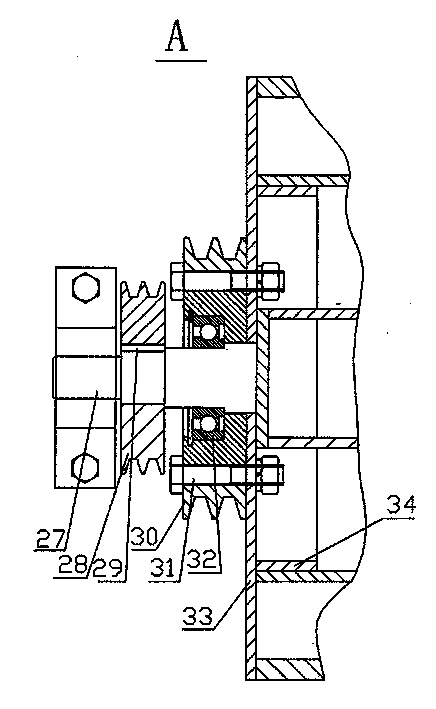

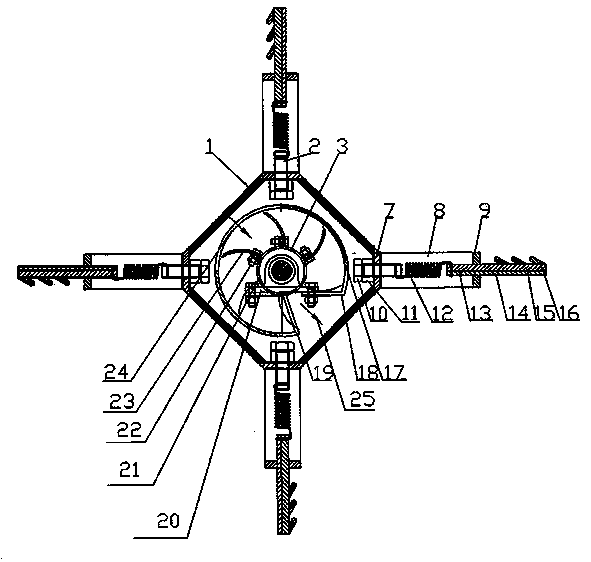

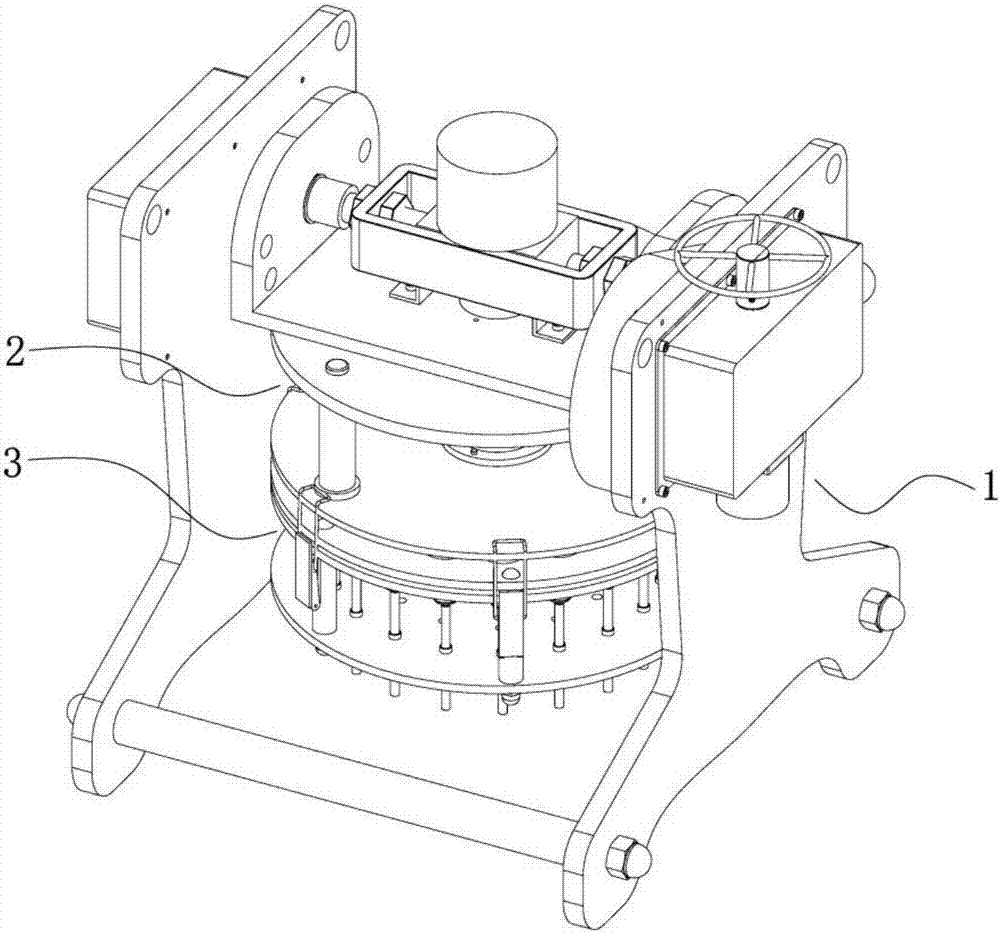

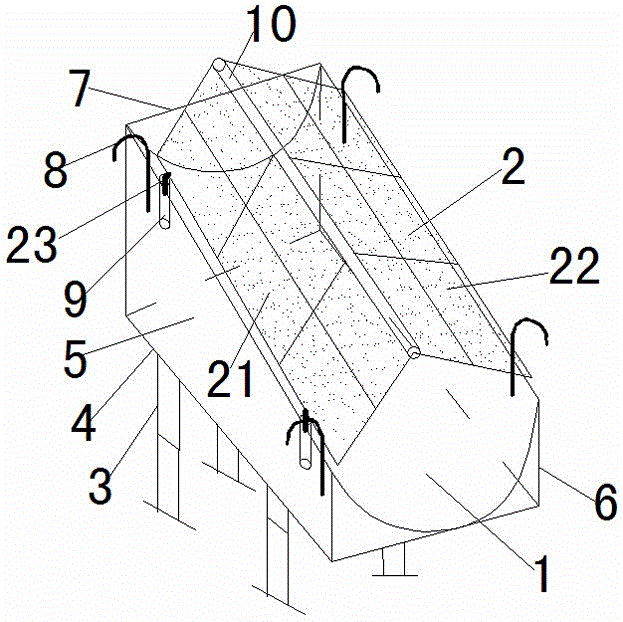

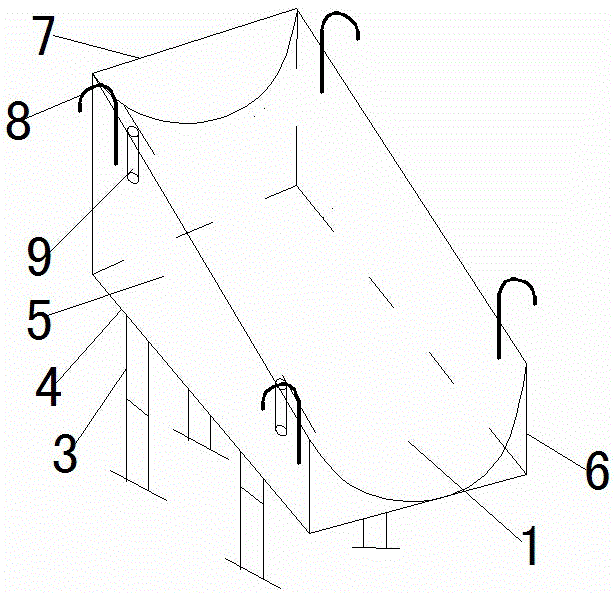

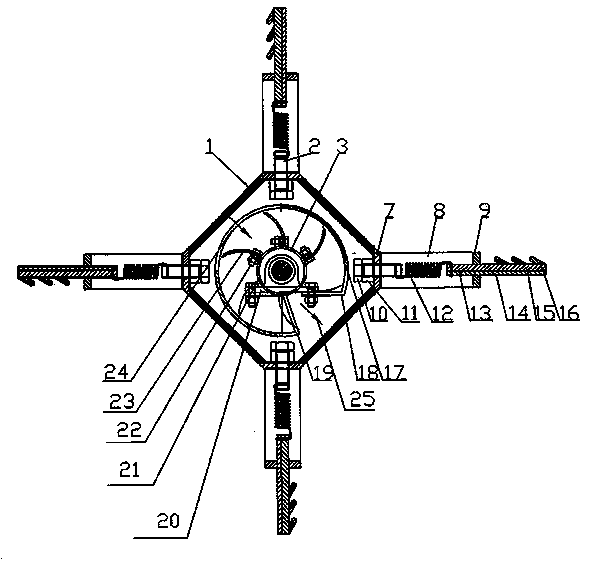

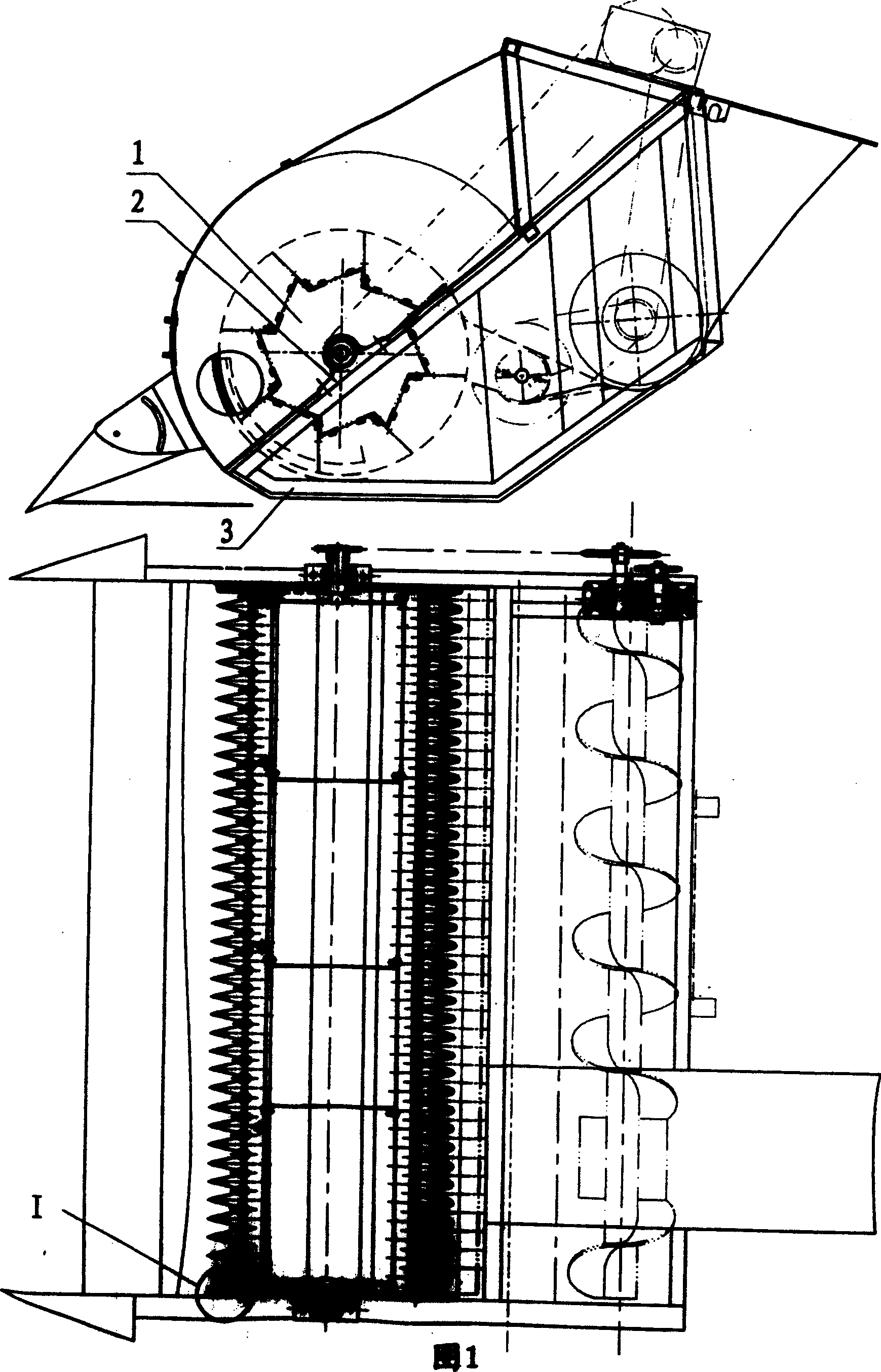

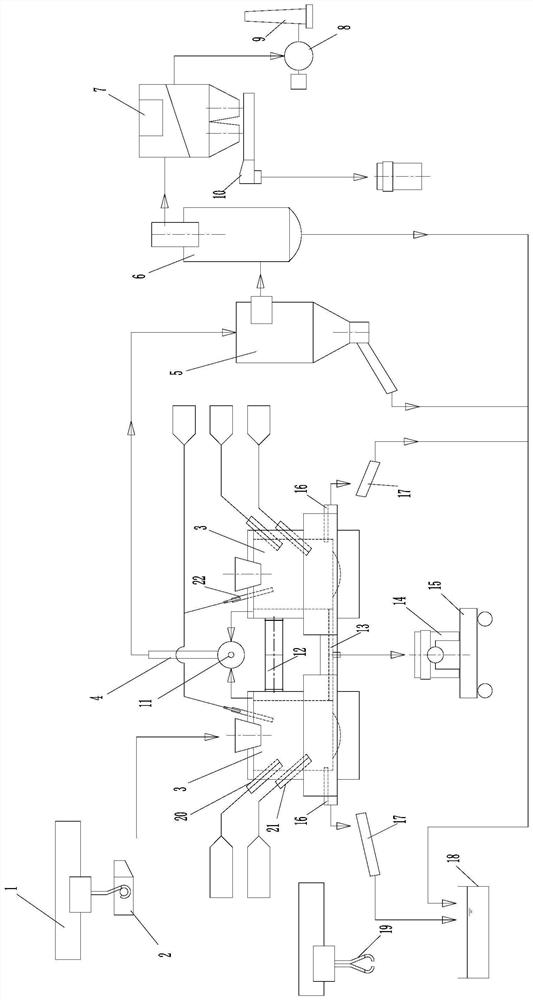

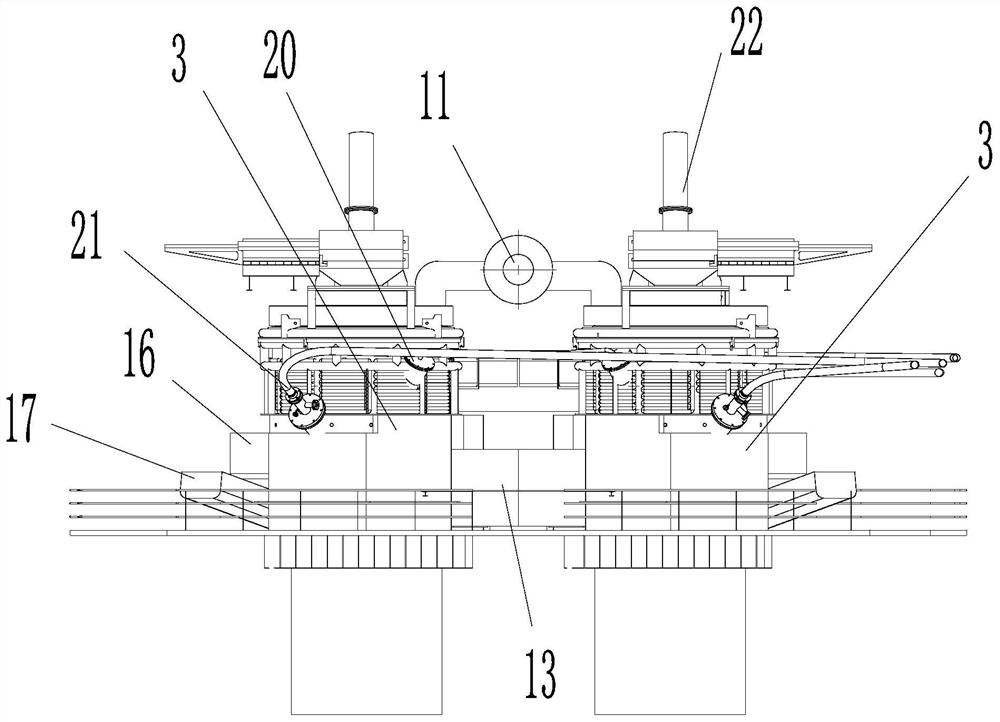

Asynchronous air-sweeping type flexible bionic retractable standing grain moving device

The invention discloses an asynchronous air-sweeping type flexible bionic retractable standing grain moving device. According to the device, a machine frame is located outside, bionic standing grain moving mechanisms are evenly distributed outside the machine frame in the radial direction, a fan mechanism is located inside the machine frame, a transmission mechanism is located at the left end of the machine frame, threaded holes are distributed in a base of the machine frame, each bionic standing grain moving mechanism is formed by a positioning bolt, a spring and a bionic standing grain moving plate, stretching and retracting of the bionic standing grain moving mechanisms are achieved through the springs, an air inlet is formed in front of a fan cover, an air outlet is formed behind the fan cover, a fan belt wheel is fixed on the left half axle through a flat key, a standing grain moving belt wheel is mounted on the outer ring of a bearing and is connected with a left baffle through a long bolt, and then the bionic standing grain moving mechanisms and the fan mechanism can rotate coaxially at different speeds. The device has the advantages that stand grain moving contact impact is small, the stand grain moving height and feeding depth are continuously adjustable, loss of grains of crops is small during stand grain moving, damage to the surfaces of the grains of crops is small, the structure is simple and compact, and overall efficiency of stand grain moving operation is high.

Owner:JILIN UNIV

Pulsed tungsten argon arc welding method

InactiveCN103894709AReduce splashReduce distortionArc welding apparatusWelding/cutting media/materialsCurrent rangeShielding gas

A pulsed tungsten argon arc welding method comprises the following steps that (1) gas proportion of protective gas is determined; (2) composition of parent material is determined; (3) composition and diameter of a soldering wire is determined; (4) the welding is conducted according to the welding process specification. The welding process of the step (4) is characterized in that the requirements of the welding process comprise the steps that (a) the protective gas is the mixed gas of argon and oxygen, wherein at room temperature, the argon is 98% in volume, and the O2, namely the oxygen is 2% in volume; (b) it is guaranteed that the droplet transition is the one-pulse-one-droplet pulse jet flow transition in the welding process. According to the technical scheme, the pulsed tungsten argon arc welding method has the advantages that the welding spatter is small, bond area performance is improved, appearance of weld forms well, all position welding are applicable, and current range is wide.

Owner:SUZHOU JIEDERUI PRECISION MACHINERY

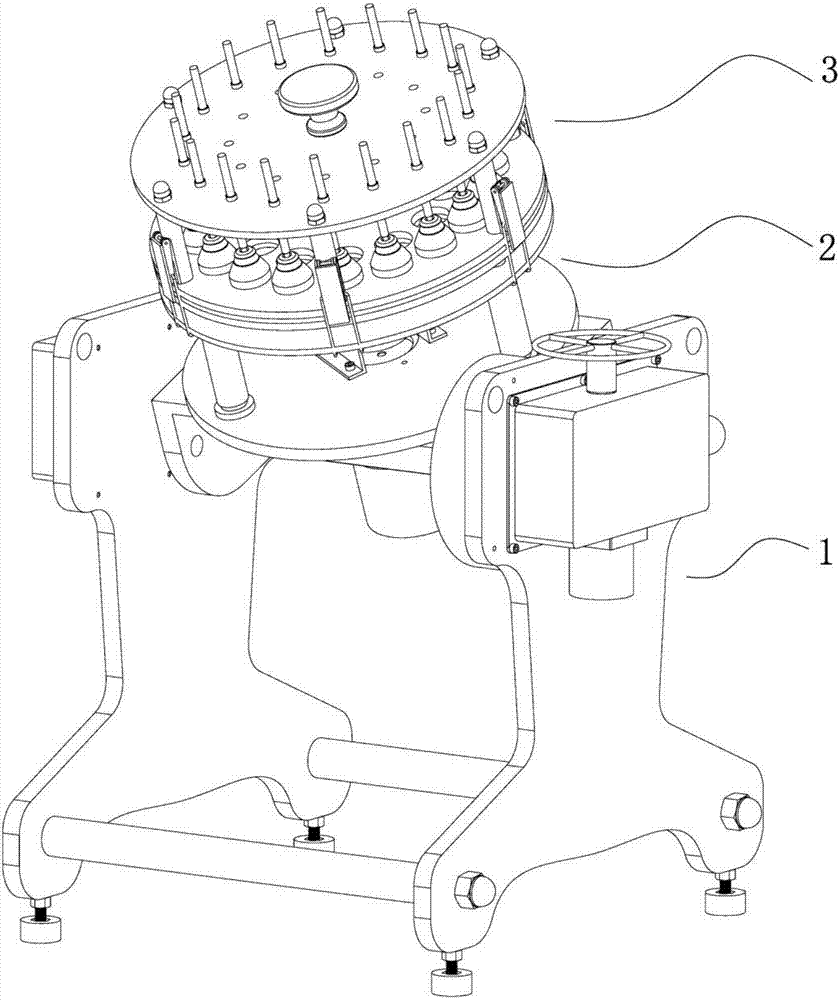

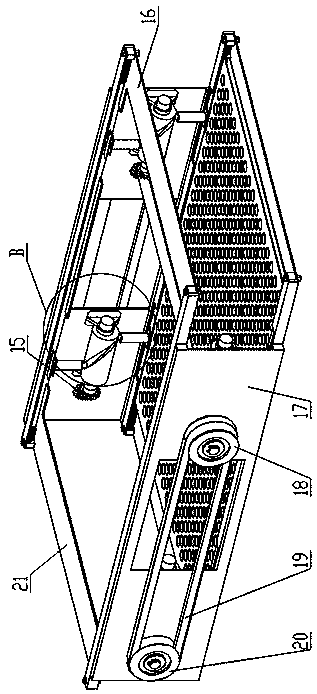

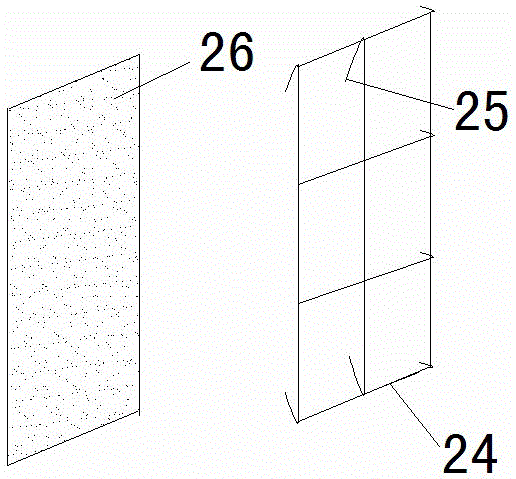

Shock-excitation material mixing and filling device and material mixing and filling method for spectral samples

ActiveCN107167352AHigh degree of automationImprove work efficiencyPreparing sample for investigationCrucibleElectric machine

The invention provides a shock-excitation material mixing and filling device and a material mixing and filling method for spectral samples. The device includes a frame, a two-phase vibrating device, a material mixing and filling apparatus, and a control unit. The method includes the steps of: 1) placing ore powders into crucibles, which are buckled vertically, in the material mixing and filling apparatus, and performing rotational turning, eccentric vibration and vertical periodical shaking to achieve complete stirring and mixing of the multi-component ore powders; 2) through action of a tilt motor, overturning the crucibles buckled vertically, and with combination of rotation, eccentric vibration and vertical periodical shaking, filling cavities in carbon rods with the mixed ore powder in the crucibles; and 3) repeating the steps to complete mixing of the ore powders in multiple batches and filling of the materials in the carbon rods. The device has creative design and structure and high automation degree, greatly improves work efficiency of material mixing and filling and has advantages on improvement of spectral analysis precision and work efficiency.

Owner:HUBEI UNIV OF TECH +1

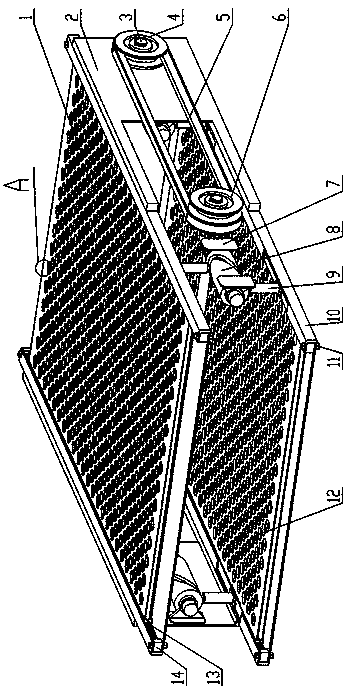

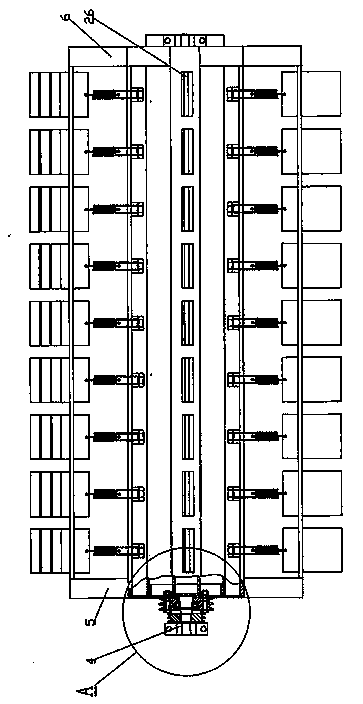

Intermittent interception type grain two-way vibration cleaning device

The invention discloses an intermittent interception type grain two-way vibration cleaning device. The intermittent interception type grain two-way vibration cleaning device comprises an upper screenmechanism, a frame, transmission mechanisms, vibration mechanisms and a lower screen mechanism; the upper screen mechanism is fixed above the frame; the lower screen mechanism is fixed below the frame; the transmission mechanisms are fixed at the externals of two sides of the frame; the vibration mechanisms are fixed in two sides of the frame; an interception sleeve is embedded in a limiting sleeve; a vibration spring is fixed below the external of the interception sleeve; the vibration spring supports the limiting sleeve to perform a reciprocating motion in the vertical direction; a stop shoulder is positioned at the upper part of the interception sleeve; a base hole is positioned at the lower part of the interception sleeve; when the stop shoulder is leveled with the upper surface of a first fixed screen plate, an interception function is exerted; when the stop shoulder of the interception sleeve is leveled with a second movable screen plate, the interception function is closed; andthrough a reciprocating motion of a guide rod, the upper screen mechanism and the lower screen mechanism are urged to generate reciprocating motions in the horizontal direction and the vertical direction to drive the spring to buffer the vibration impact. The intermittent interception type grain two-way vibration cleaning device improves the operation stability, and reduces the grain cleaning lossrate and the impurity rate.

Owner:JILIN UNIV

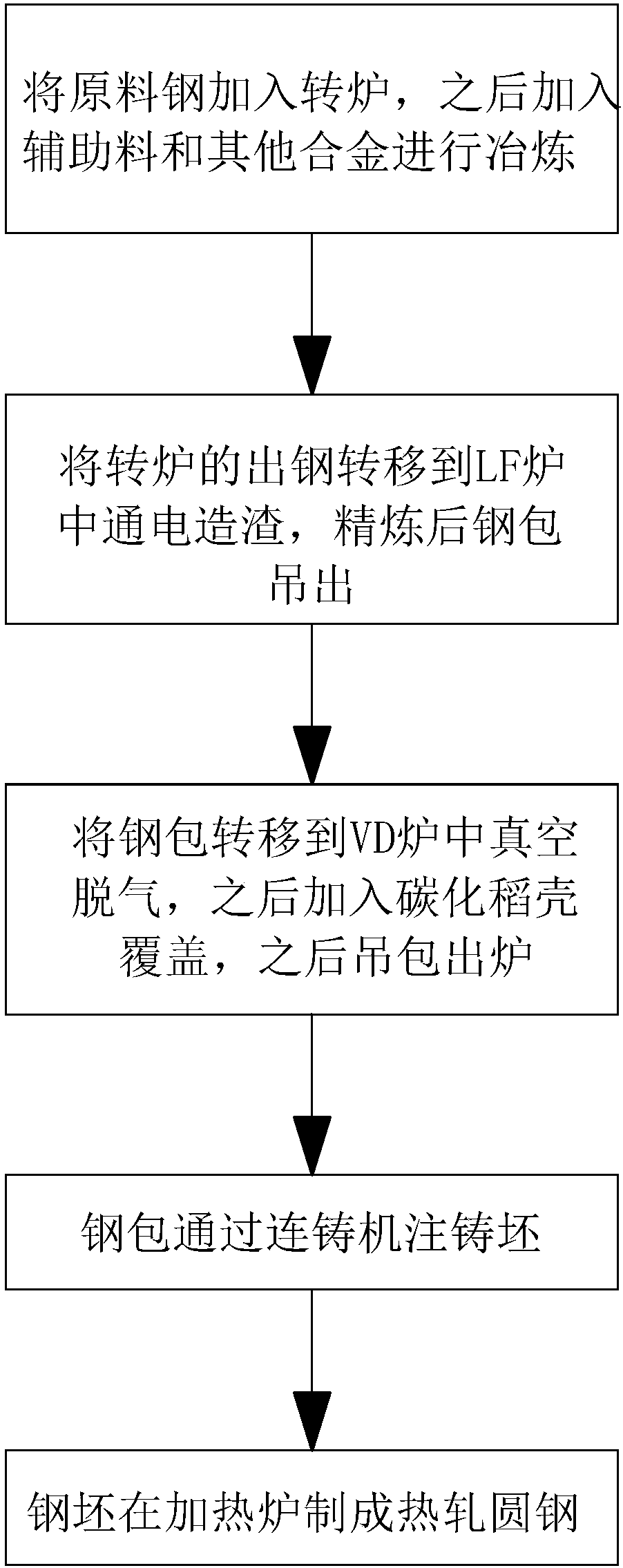

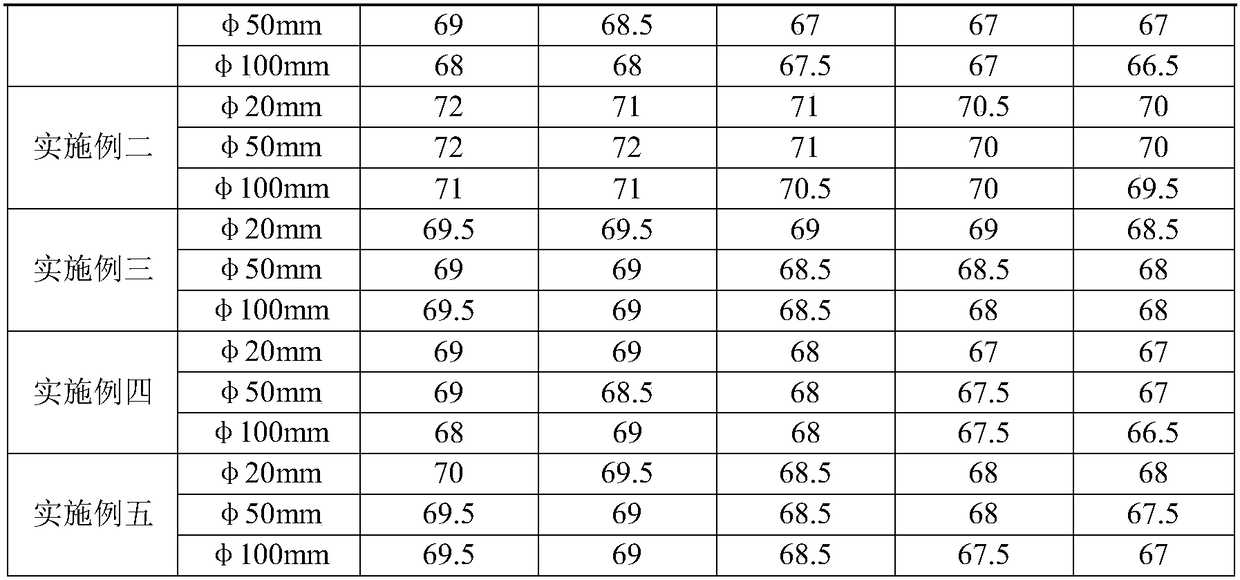

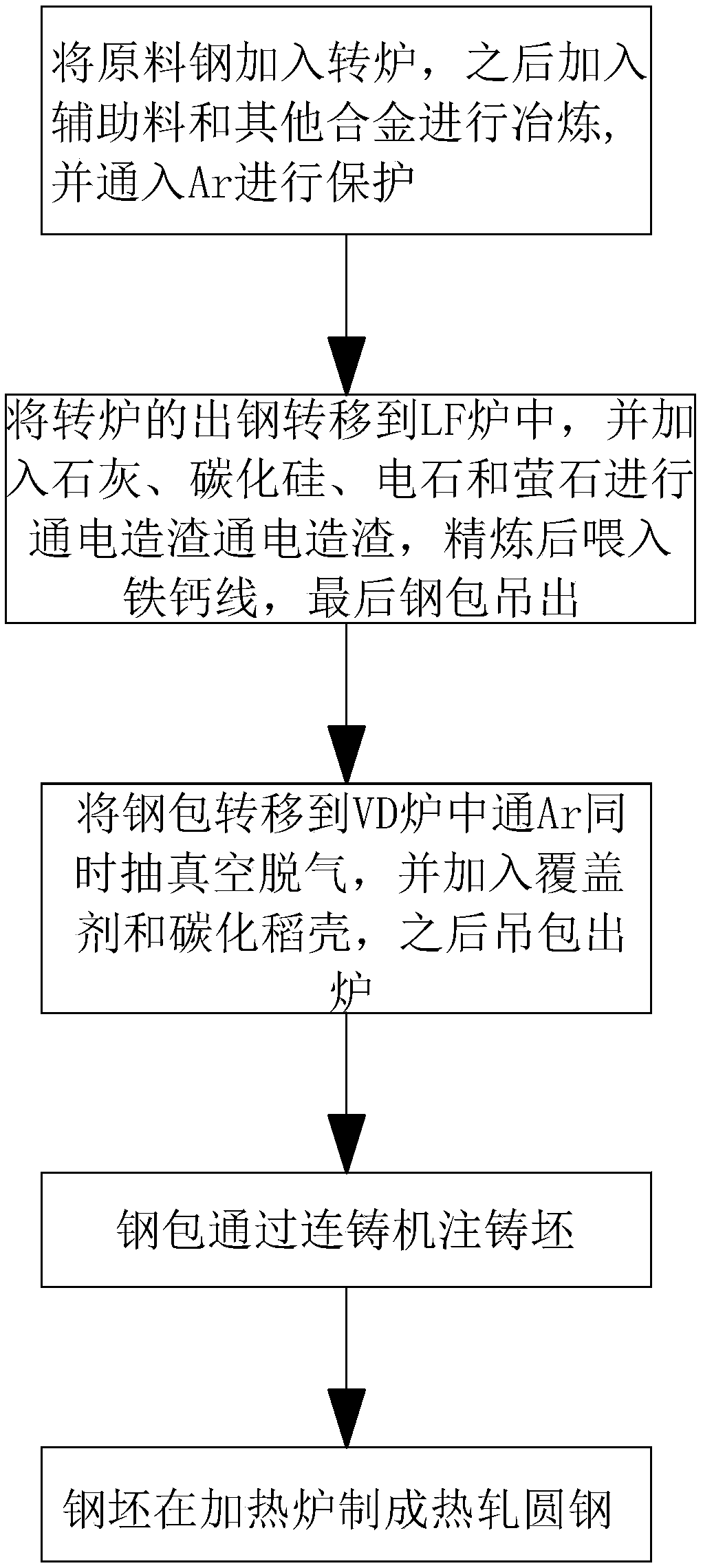

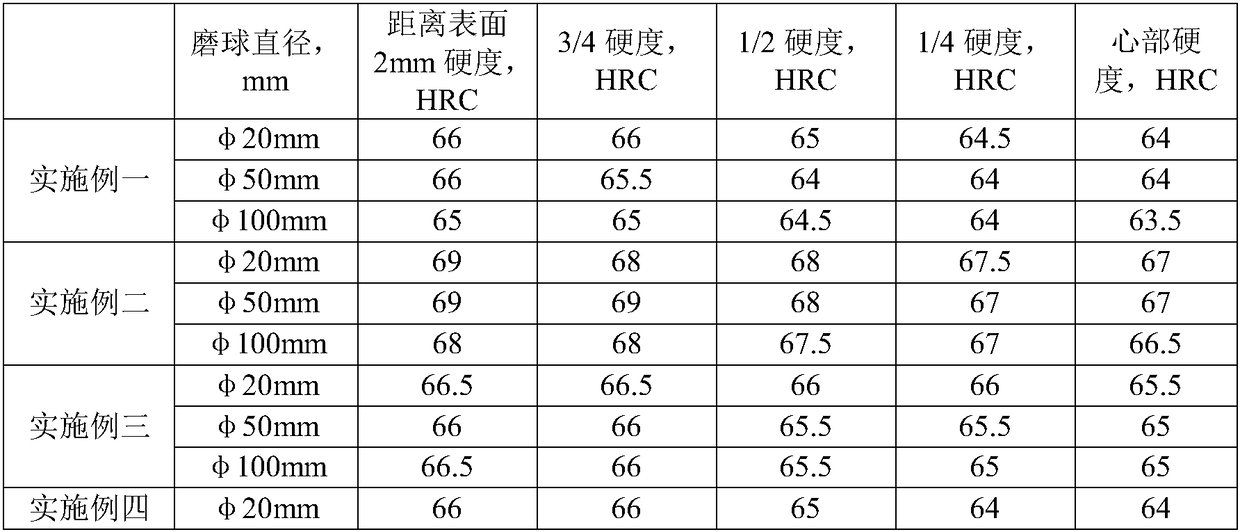

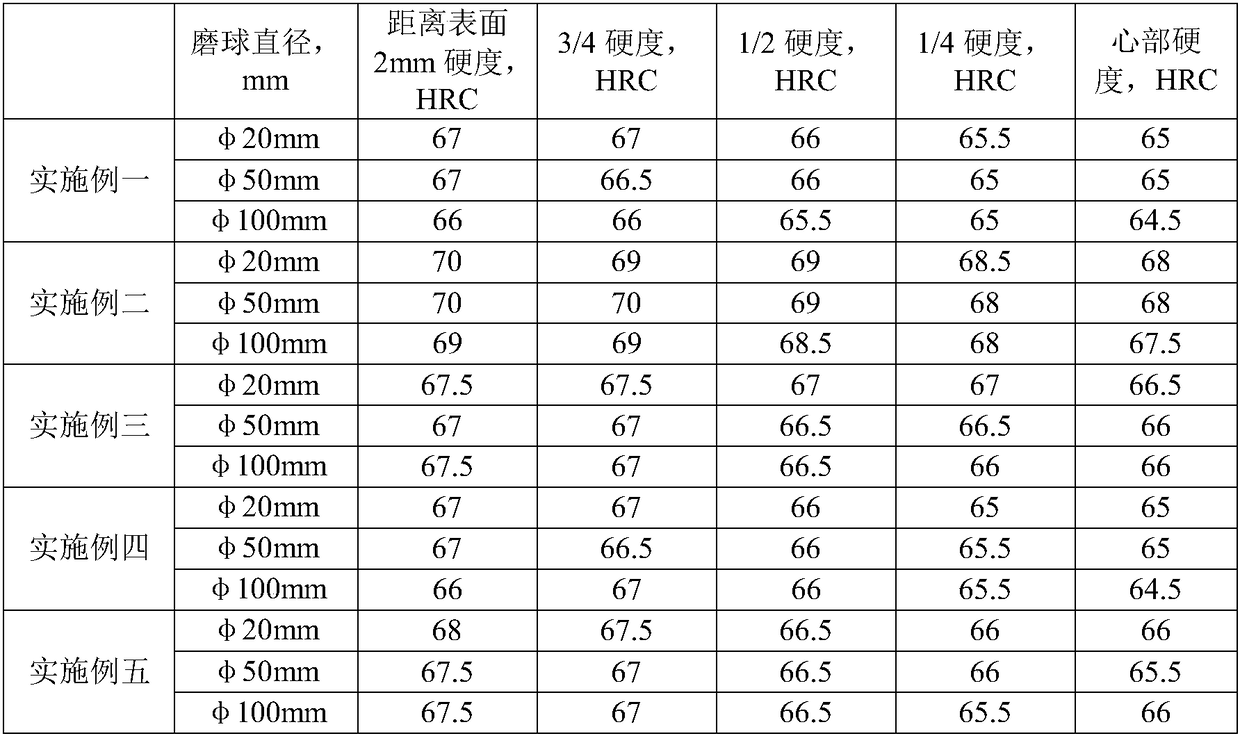

Hot-rolled round steel for high-carbon-manganese-chromium grinding ball and manufacturing method thereof

The invention provides hot-rolled round steel for a high-carbon-manganese-chromium grinding ball. The hot-rolled round steel is prepared from the following components: 0.72 to 0.82 percent of C, 0.17to 0.35 percent of Si, 0.70 to 0.90 percent of Mn, 0.010 to 0.030 percent of P, 0.010 to 0.030 percent of S, 0.50 to 0.70 percent of C, 0.20 to 0.30 percent of In, 0.10 to 0.20 percent of Ag, 0.15 to0.25 percent of Cu, 0.080 to 0.100 percent of Ga, 0.20 to 0.26 percent of Ni, 0.10 to 0.14 percent of Zn, 0.14 to 0.16 percent of Sn and the balance of Fe and unavoidable impurities. The round steel provided by the invention contains relatively high elements including carbon, manganese, tin and the like and can be obtained by refining a casting-state structure of steel, so that the prepared grinding ball has relatively great rigidity; when an object with relatively great rigidity is ground, good wear resistance can be ensured; meanwhile, the round steel also contains the chromium element withrelatively high content, so that the round steel has a relatively strong corrosion-resisting capability and the round steel is suitable for being used in various fields for grinding.

Owner:TIANJIN RONGCHENG UNITED IRON & STEEL GRP CO LTD

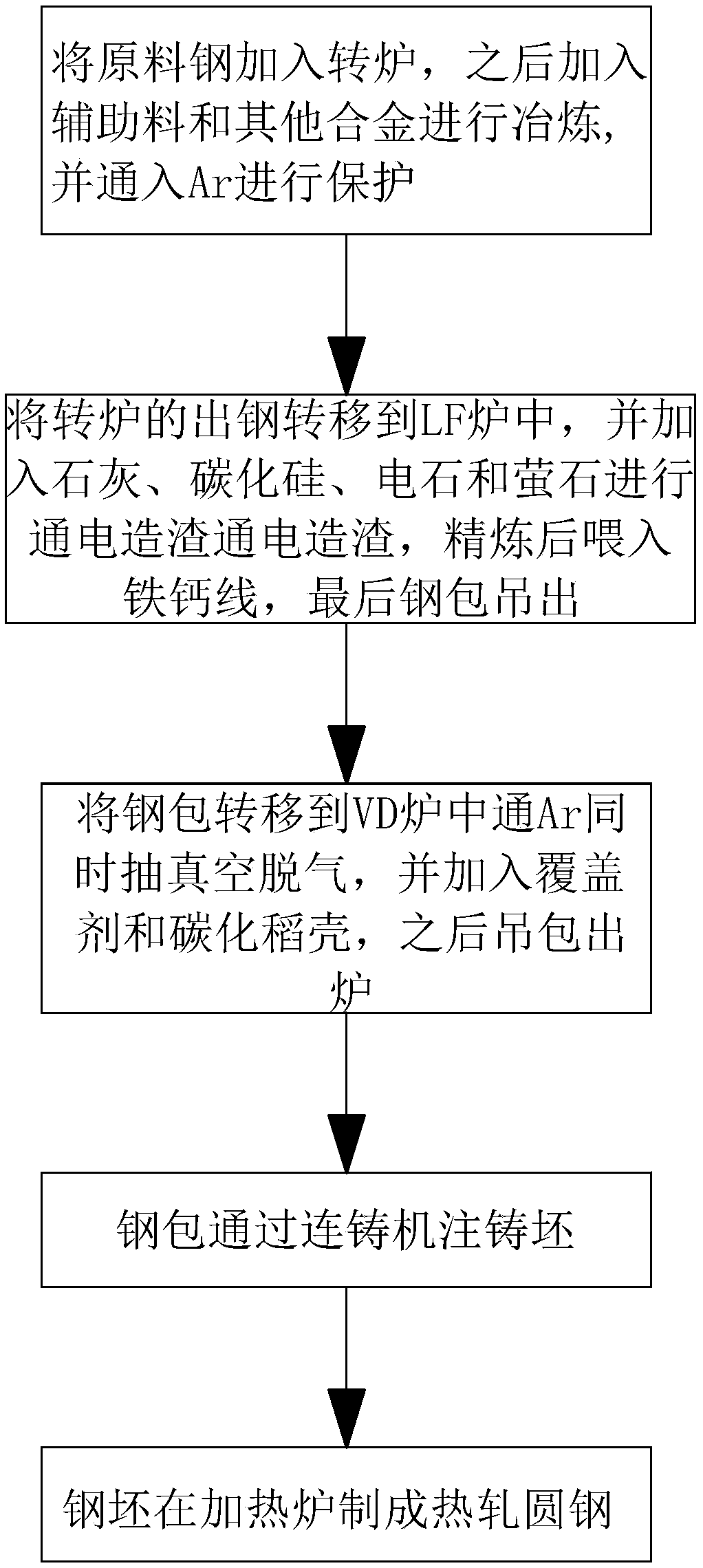

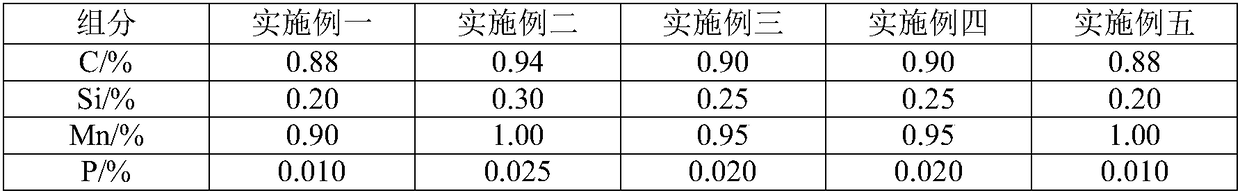

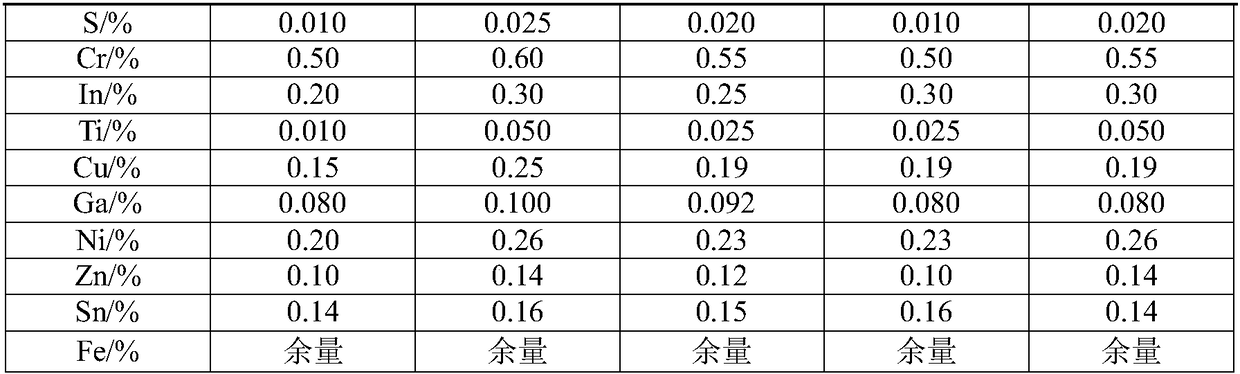

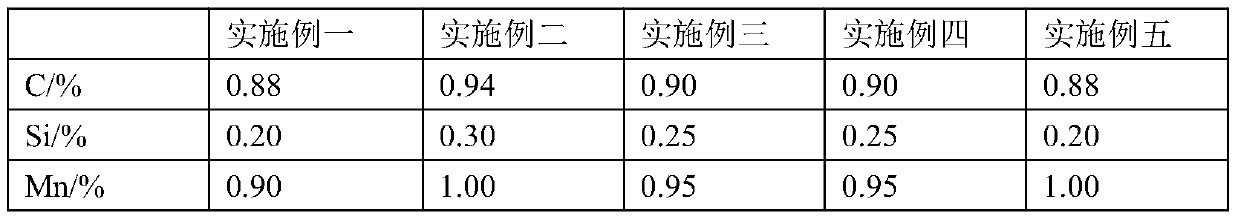

Steel special for abrasion-resistant grinding ball and preparation method of steel

The invention provides steel special for an abrasion-resistant grinding ball. The steel special for the abrasion-resistant grinding ball comprises 0.88%-0.94% of C, 0.20%-0.30% of Si, 0.90%-1.00% of Mn, no more than 0.025% of P, no more than 0.025% of S, 0.50%-0.60% of Cr, 0.010%-0.050% of Ti, 0.20%-0.30% of In, no more than 0.25% of Cu, 0.080%-0.100% of Ga, 0.20%-0.26% of Ce, 0.10%-0.14% of Zn, 0.14%-0.16% of Sn, and the balance Fe and inevitable impurities. By adoption of the technical scheme, crystals of the steel are fine, and the internal density of the steel is high; the grinding ball prepared from the steel is high in hardness and good in abrasion resistance; and the steel special for the abrasion-resistant grinding ball is low in production cost and suitable for being used for grinding in various fields.

Owner:天津荣程联合钢铁集团有限公司

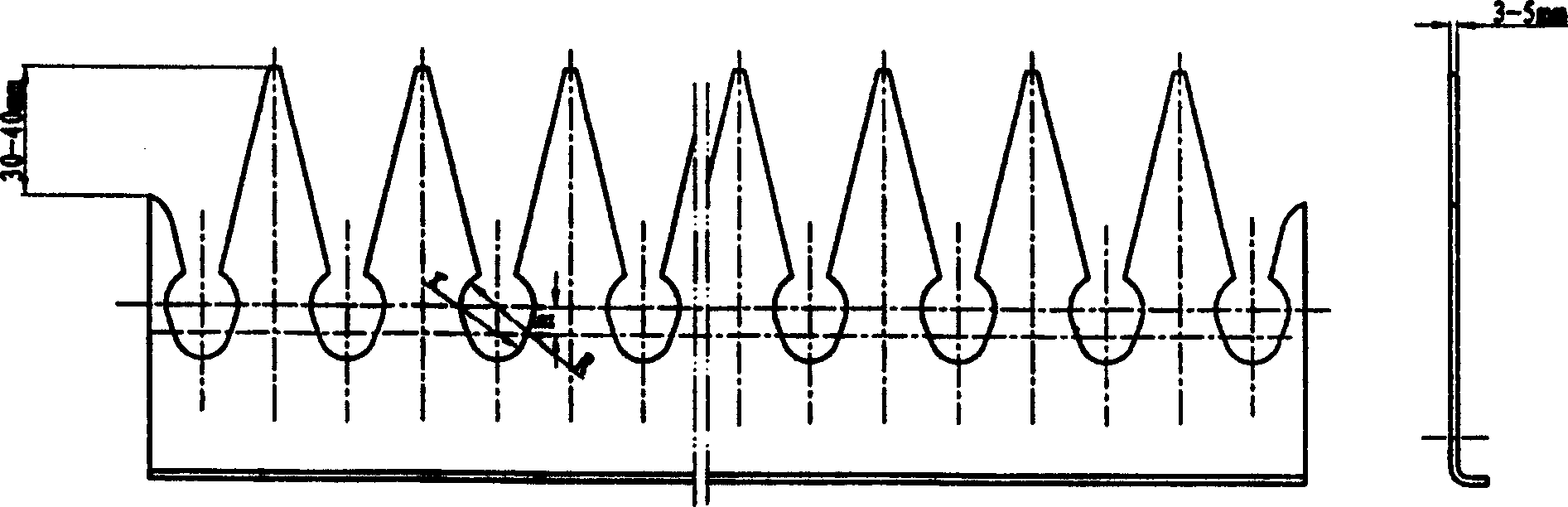

Technology for preventing water drop splashing of vertical current force cooling tower

The invention discloses an anti-water drops splashing technique of a cooling tower of vertical type flow force, which mainly includes the following steps that: A. a water retaining member is provided to make the upper section and the lower section of the body upright sections; the water retaining member is connected with a part bending backward and the middle part is an upright section; B. the surface of the body is provided with an insertion hole, and the other face is provide with a positioning hole plate corresponding with the insertion hole. The manufactured water retaining member of the cooling tower of vertical type flow force is arranged at the top of the cooling tower with simple assembly and easy installation and maintainance; As the five-folds water retaining design is adopted also with a hollow convex strip arranged, a better water way design is formed, which makes the tiny vapor and fog agglomerate into big water drops during flowing the winding path, and then fall back to the inside of the cooling tower, reducing the splashing loss of water drops; the invention has a high intensity and a stable structure performance with high promotiation value.

Owner:SHANGHAI LIANGJI COOLING EQUIP CO LTD

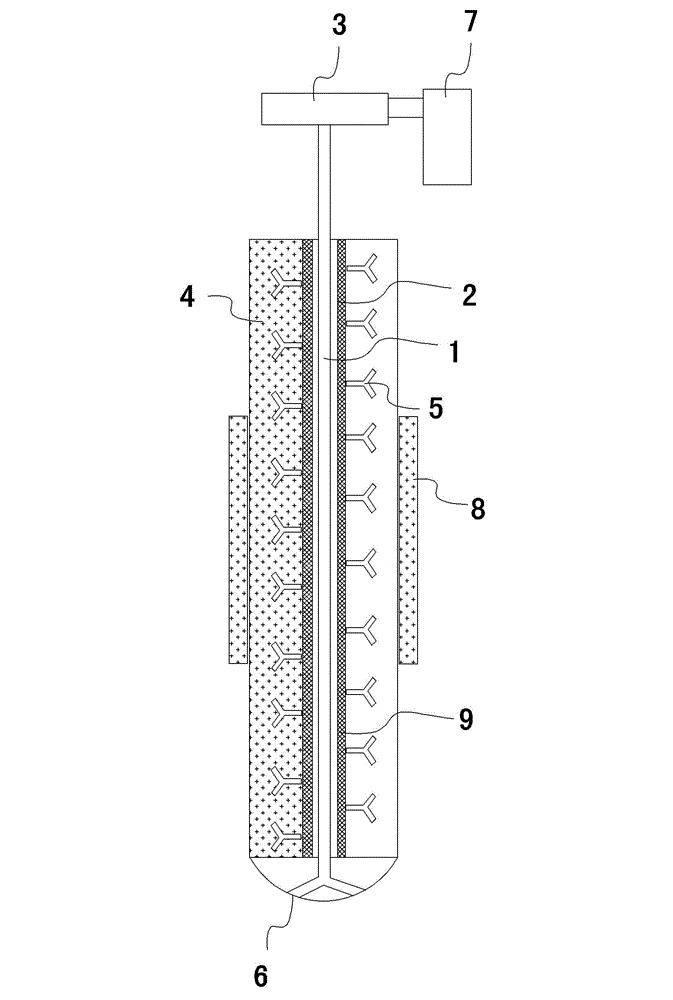

Double-hole rotary fireproof spray gun

InactiveCN102978324AReduce metal splash lossReduce air bubblesCharge manipulationEngineeringPower transmission

The invention belongs to the field of molten iron desulfuration equipment, and in particular relates to a double-hole rotary fireproof spray gun. The double-hole rotary fireproof spray gun comprises a gun body, wherein the gun body comprises a central spray pipe (1), a protective pipe (2), a fireproof material layer (4), a rotating mechanism (7) and a flange plate (3) fixedly connected with the central spray pipe (1); the central spray pipe (1) is sleeved in the protective pipe (2); the fireproof material layer (4) is arranged outside the protective pipe (2); in the fireproof material layer (4), a framework (5) is fixed outside the protective pipe (2); the lower end of the central spray pipe (1) is provided with two tail jet nozzles (6); the power output by the rotating mechanism (7) is transmitted to the flange plate (3); and the bottom end of the gun body is of a semi-spherical structure. The double-hole rotary fireproof spray gun is simple in structure, good in effect of mixing a desulfurizing agent and molten iron and low in splashing strength.

Owner:营口东邦环保科技股份有限公司

High-carbon and low-alloy steel for grinding balls and manufacturing method thereof

The invention discloses high-carbon and low-alloy steel for grinding balls. The steel comprises the following components, by mass percentage: 0.88-0.94% of C, 0.20-0.30% of Si, 0.90-1.00% of Mn, lessthan or equal to 0.025% of P, less than or equal to 0.025% of S, 0.50-0.60% of Cr, 0.010-0.050% of Ti, 0.20-0.30% of In, less than or equal to 0.25% of Cu, 0.080-0.100% of Ga, 0.20-0.26% of Ni, 0.10-0.14% of Zn, 0.14-0.16% of Sn and the balance Fe and inevitable impurities. The steel has the advantages that the production cost is relatively low, meanwhile, high-content carbon, manganese, tin, titanium and other elements are contained in the steel, so that the as-cast structure of the steel can be refined, and therefore the hardness of the grinding balls can be greatly improved, and good wear resistance of the grinding balls in the grinding process of an object with large hardness can be ensured; and in addition, high-content chromium is further contained in the steel, so that the grindingballs can also have relatively strong corrosion resistance, and therefore the grinding balls can be suitable for being used for grinding in a variety of fields.

Owner:TIANJIN RONGCHENG UNITED IRON & STEEL GRP CO LTD

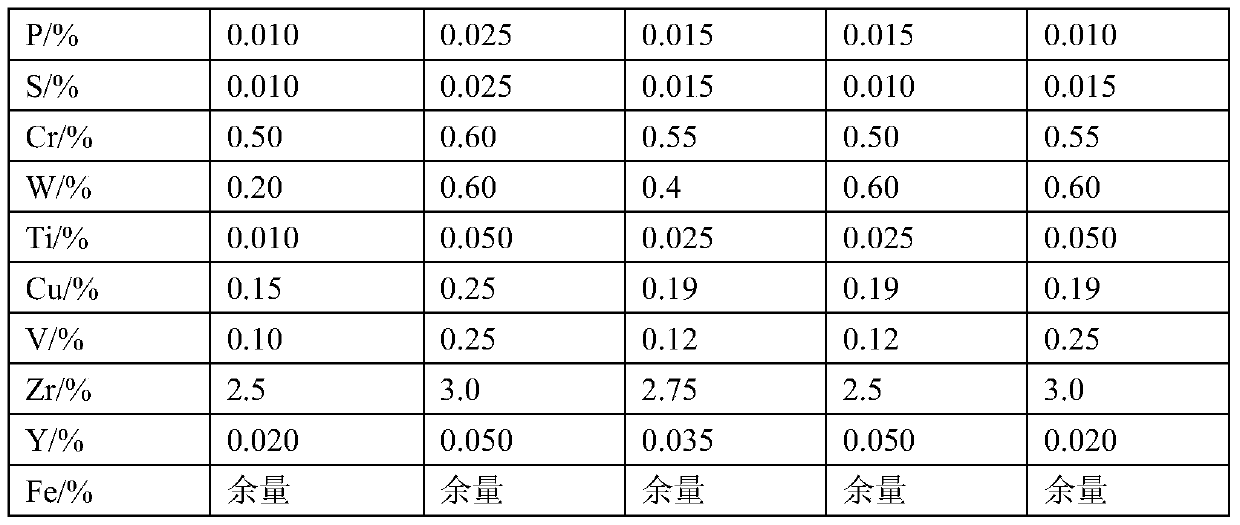

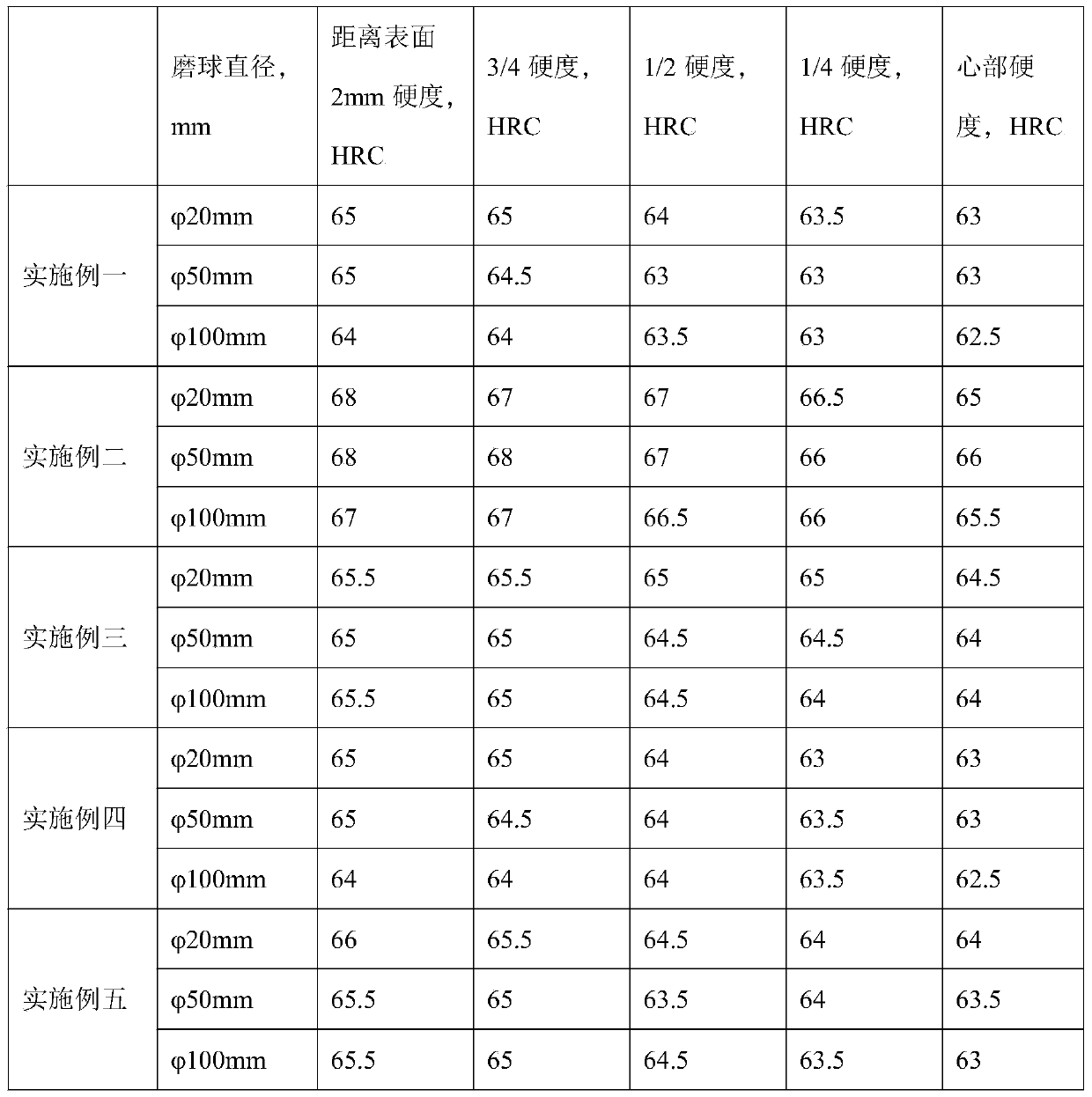

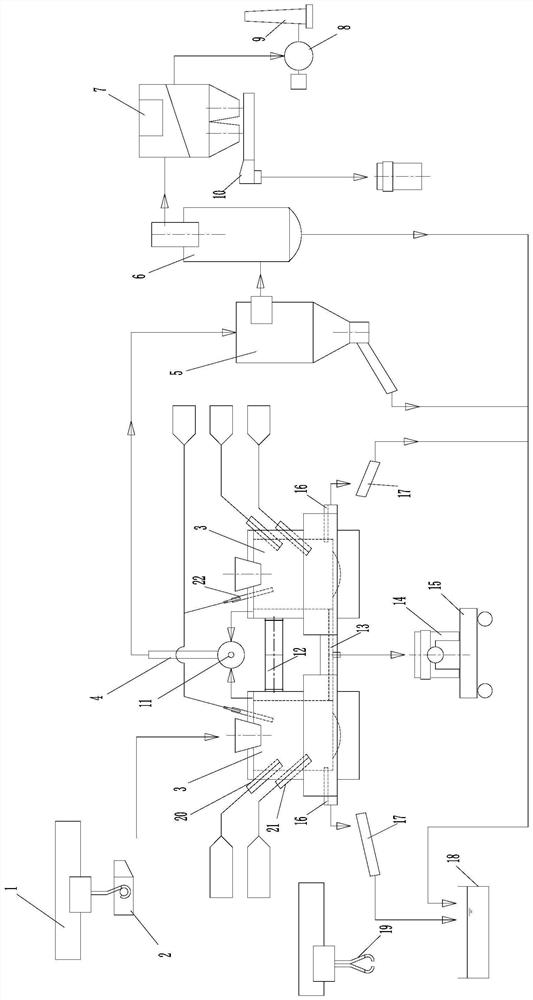

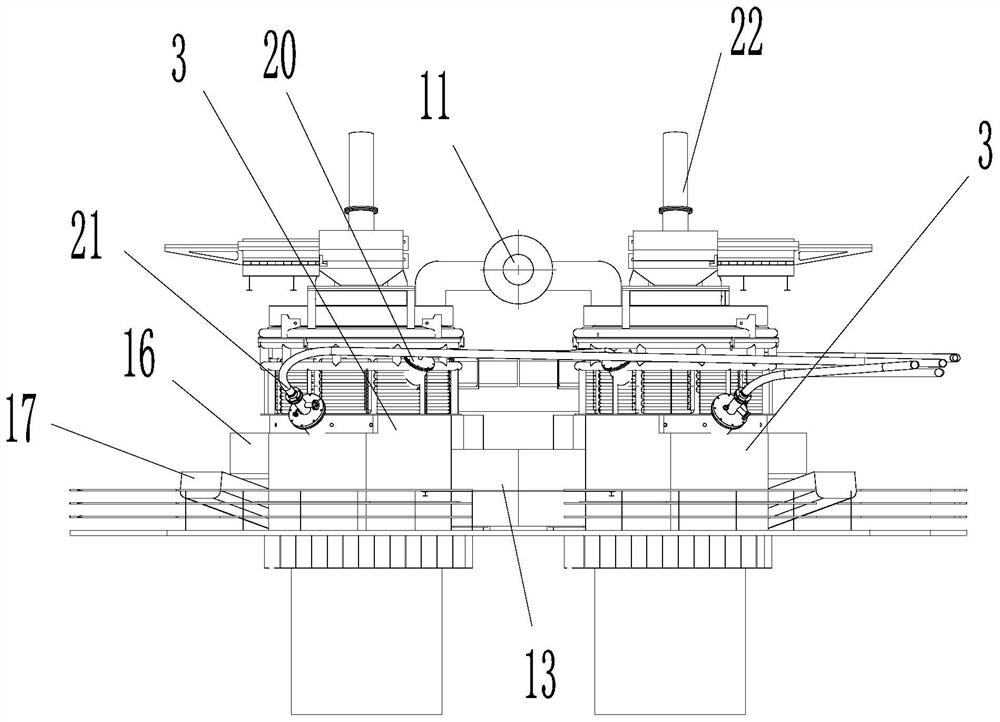

A kind of wear-resistant steel and its production process

ActiveCN108315645BRefining as-cast structureHigh hardnessProcess efficiency improvementWear resistantUltimate tensile strength

The invention relates to wear-resistant steel and belongs to the technical field of metal smelting. The wear-resistant steel is prepared from the following components in percent by mass: 0.88-0.94% ofC, 0.20-0.30% of Si, 0.90-1.00% of Mn, 0.50-0.60% of Cr, 0.20-0.60% of W, 0.10-0.25% of V, 2.50-3.00% of Zr, 0.010-0.050% of Ti, 0.020-0.050% of Y, less than or equal to 0.025% of P, less than or equal to 0.025% of S, less than or equal to 0.25% of Cu and the balance of Fe and inevitable impurities. The wear-resistant steel has the beneficial effects that the problems of low strength and poor wear resistance of the existing low-carbon wear-resistant steel is solved; the wear-resistant steel is finer in crystal and fuller in internal density, and a grinding ball prepared by the wear-resistantsteel is larger in hardness and good in wear resistance.

Owner:TIANJIN RONGCHENG UNITED IRON & STEEL GRP CO LTD

Iron adding process-based medium-high silicon molten iron desilication method

InactiveCN103667579AStrong process flexibilityDesilication reaction time is sufficientProcess efficiency improvementSlagPre treatment

The invention discloses an iron adding process-based medium-high silicon molten iron desilication method, and belongs to the technical field of molten iron pretreatment. The process of adding molten iron into a molten iron ladle by utilizing an iron mixing furnace / vehicle serves as molten iron desilication reaction time in a melting furnace; the potential energy of iron molten serves as stirring power of the melting furnace. A solid oxidizer and a slag-regulating agent in the same proportion as that of the iron flow of the iron mixing furnace / vehicle are added continuously to realize high-efficiency desilication. The method has the advantages that the burden of high-silicon molten iron in converter smelting is lightened; the cost of steel smelting is reduced; moreover, the process is simple; the operability is high; the equipment investment is low; the operating cost is low.

Owner:德龙钢铁有限公司

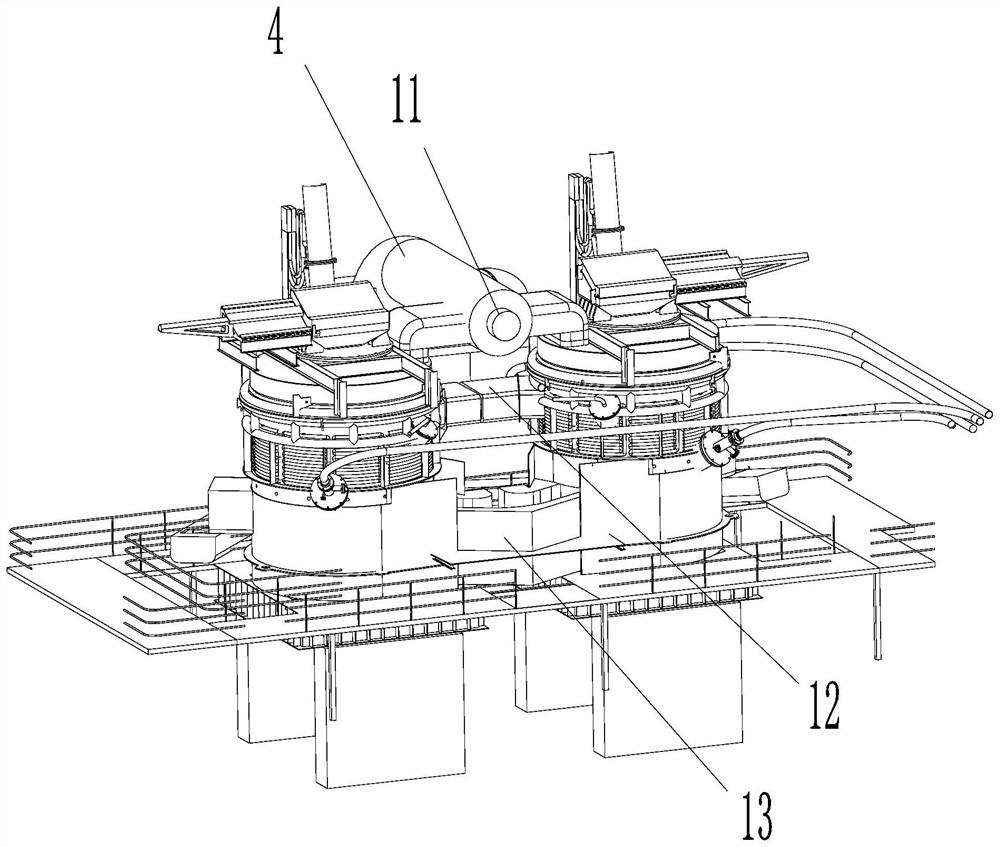

Method for modifying molten steel slag by using double-molten-pool furnace

The invention discloses a method for modifying molten steel slag by using a double-molten-pool furnace. The method comprises the following steps that the double-molten-pool furnace is provided: a furnace body of the double-molten-pool furnace comprises two molten pools, the two molten pools are communicated through a furnace body connecting flue on the furnace body, a middle high-temperature flue is arranged between the two molten pools, one end of the middle high-temperature flue is connected with a powder receiving system, and the other end of the middle high-temperature flue is connected with one of the two molten pools through a flue gas guide switching valve; and the two molten pools are alternately used as an oxidation molten pool and a reduction molten pool by switching the flue gas guide switching valve, and comprehensive treatment of steel slag, zinc-containing fly ash and paragenic ore difficult to dissociate is achieved through the oxidation molten pool and the reduction molten pool. According to the method, steel slag can be modified into iron-making reducing slag to serve as a concrete admixture to be widely utilized, alkali metal harmful to smelting in fly ash of a steel mill can be removed, and meanwhile, a melting and dissociation method for paragenetic ore difficult to dissociate in the nature is provided.

Owner:MOUNTOP GRP CO LTD

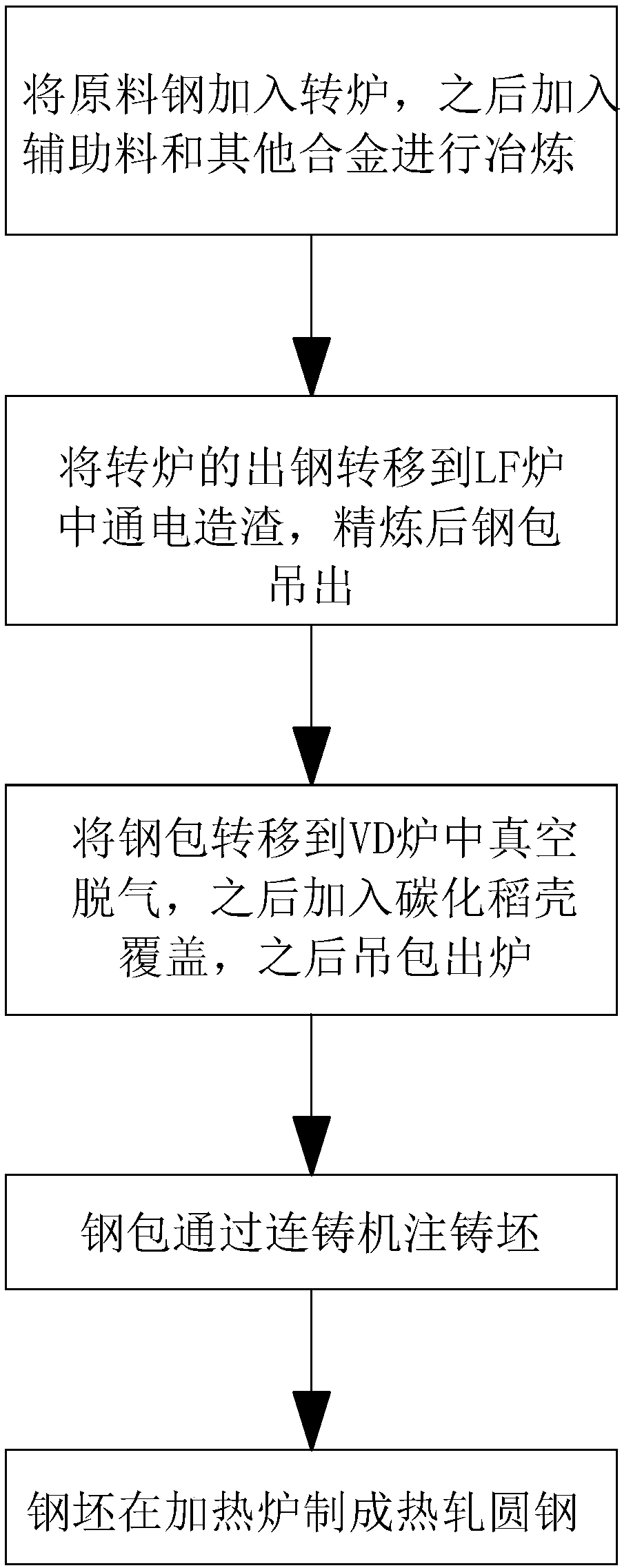

High carbon, manganese and chromium hot rolled round steel for grinding balls and manufacturing method thereof

The invention relates to high carbon, manganese and chromium hot rolled round steel for grinding balls. The high carbon, manganese and chromium hot rolled round steel for grinding balls is prepared from the following components in percentage by mass: 0.72-0.82% of C, 0.17-0.35% of Si, 0.70-0.90% of Mn, 0.010-0.030% of P, 0.010-0.030% of S, 0.50-0.70% of Cr, 0.10-0.20% of In, 0.20-0.30% of Ag, 0.15-0.25% of Cu, 0.12-0.18% of Ga and the balance of Fe and inevitable impurities. The round steel contains relatively more elements such as carbon and manganese, so that the grinding balls prepared therefrom have relatively great hardness, and good wear resistance can be ensured when objects with relatively great grinding hardness are ground; meanwhile, the round steel also contains relatively morechromium, so that the round steel has a relatively good ability of resisting corrosion, and the round steel is suitable for being used to grind in various fields.

Owner:TIANJIN RONGCHENG UNITED IRON & STEEL GRP CO LTD

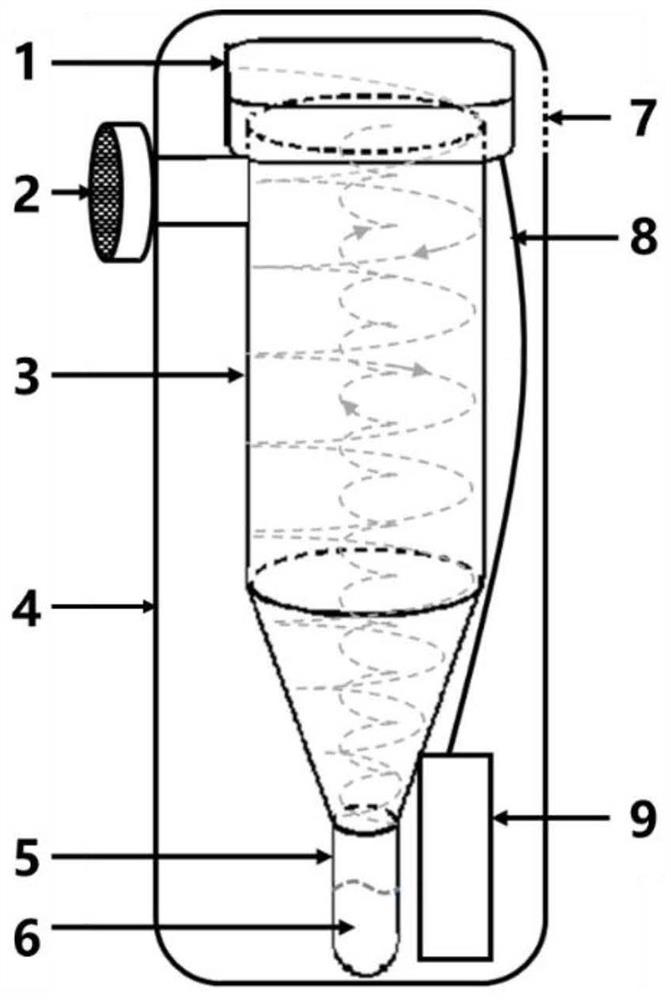

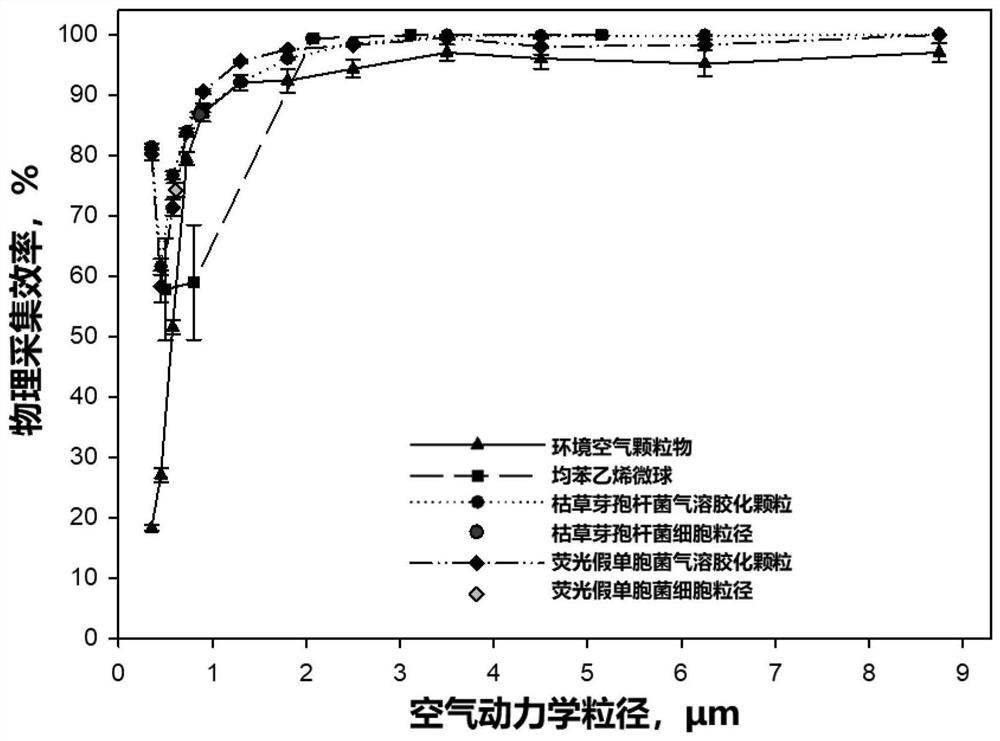

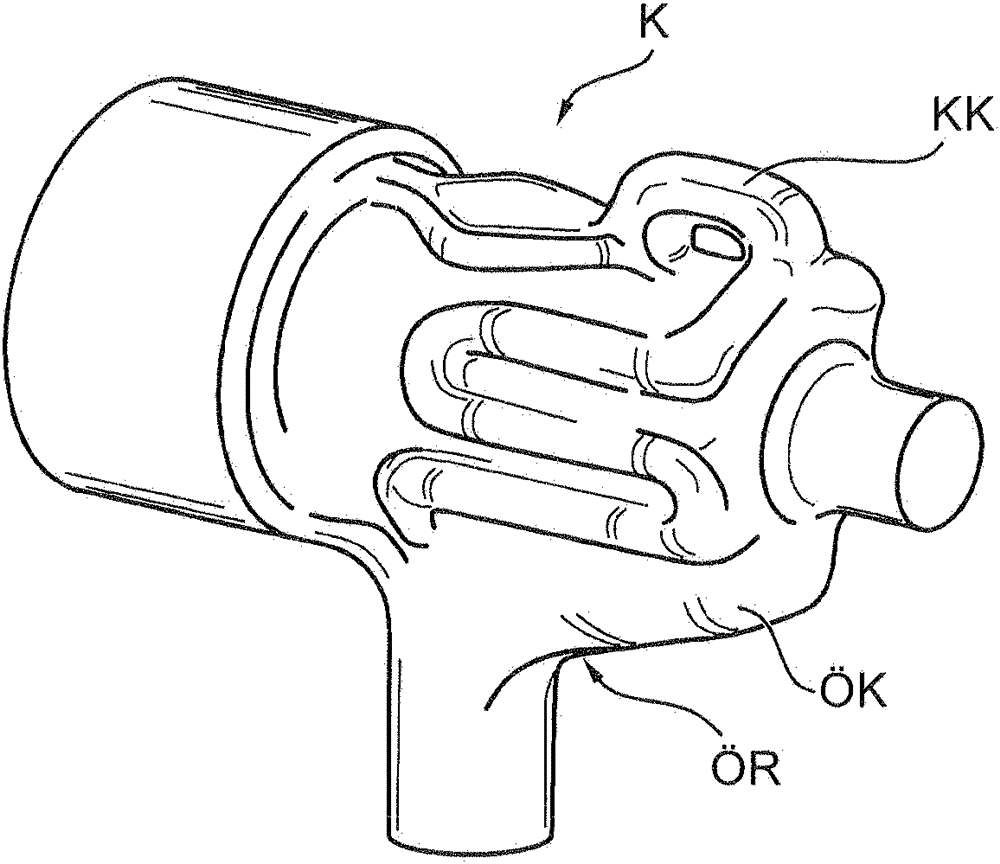

Portable large-flow liquid type biological aerosol cyclone sampler

PendingCN111751170AGuaranteed vital activityReduce lossesWithdrawing sample devicesMicroorganismEngineering

The invention discloses a portable large-flow liquid type biological aerosol cyclone sampler which comprises a large-flow fan, a cyclone sampling tube, a sampling centrifugal tube and a power supply.The main body of the cyclone sampling tube is cylindrical, and the lower part of the cyclone sampling tube is conical funnel-shaped; an air inlet pipe is arranged at the upper part of the cyclone sampling tube; a filter screen is arranged at the outer end of the air inlet pipe; the large-flow fan is arranged at the top end of the cyclone sampling tube; the sampling centrifugal tube is connected with the bottom end of the cyclone sampling tube, and liquid sampling media are contained in the sampling centrifugal tube. Portable and efficient large-flow air collection is achieved through the large-flow fan, and meanwhile, the life activity of microorganism particles is guaranteed through the liquid sampling medium; secondary aerosolization and sampling liquid splashing losses are reduced; subsequent qualitative and quantitative analysis of biological aerosol is facilitated; and the sampler has a good application prospect in biological aerosol research.

Owner:PEKING UNIV

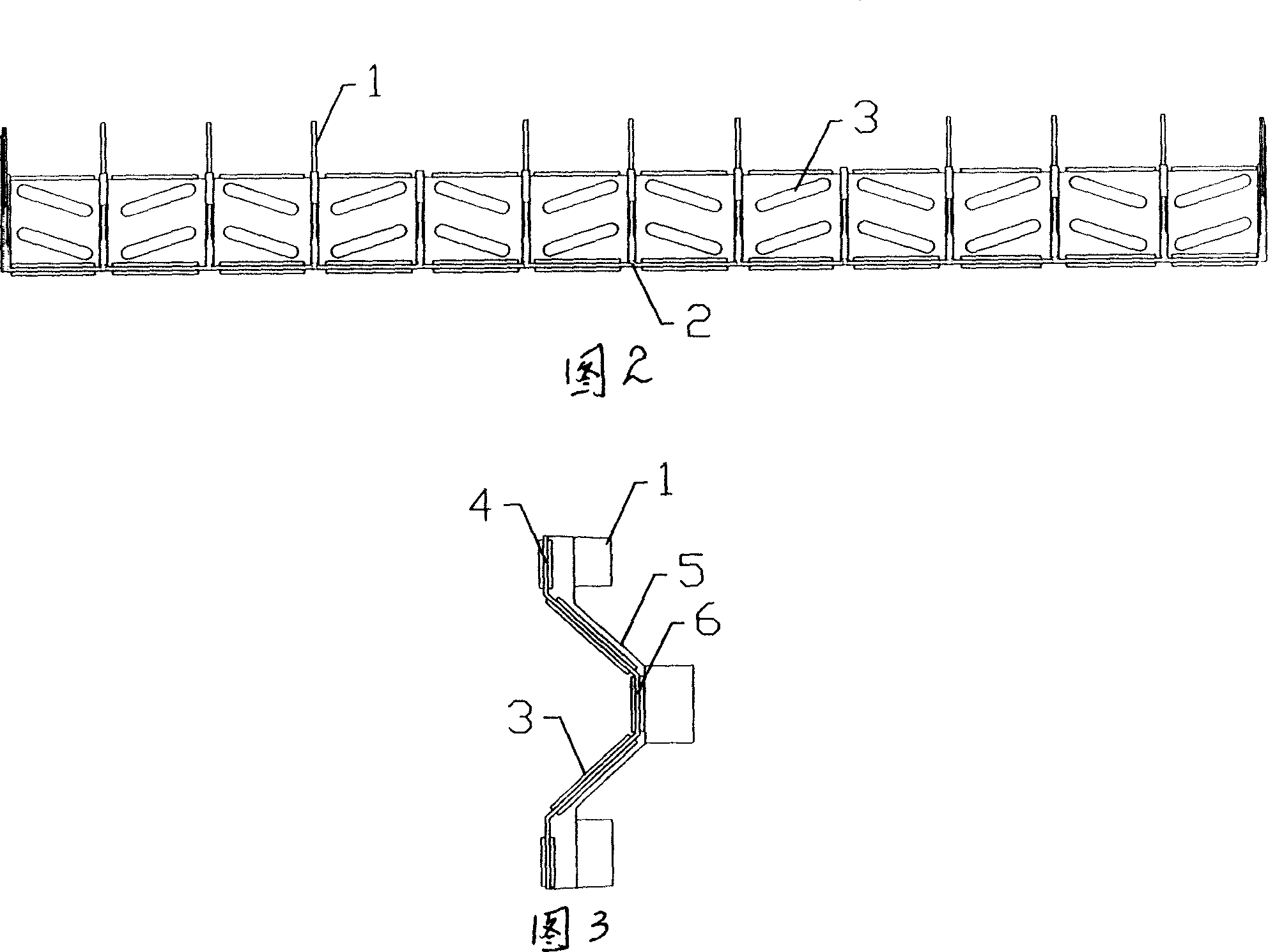

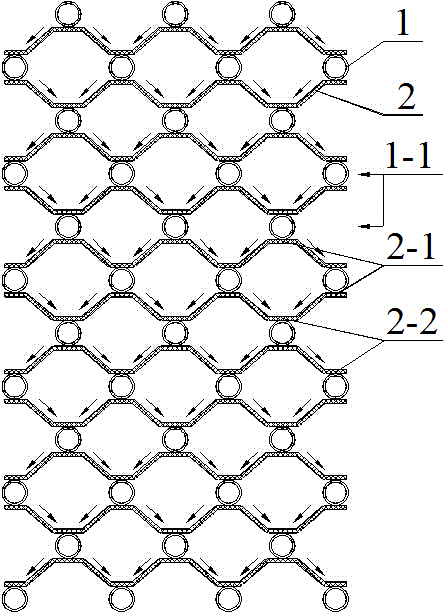

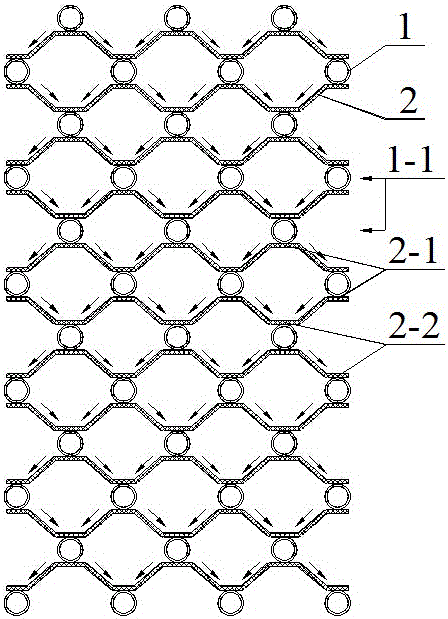

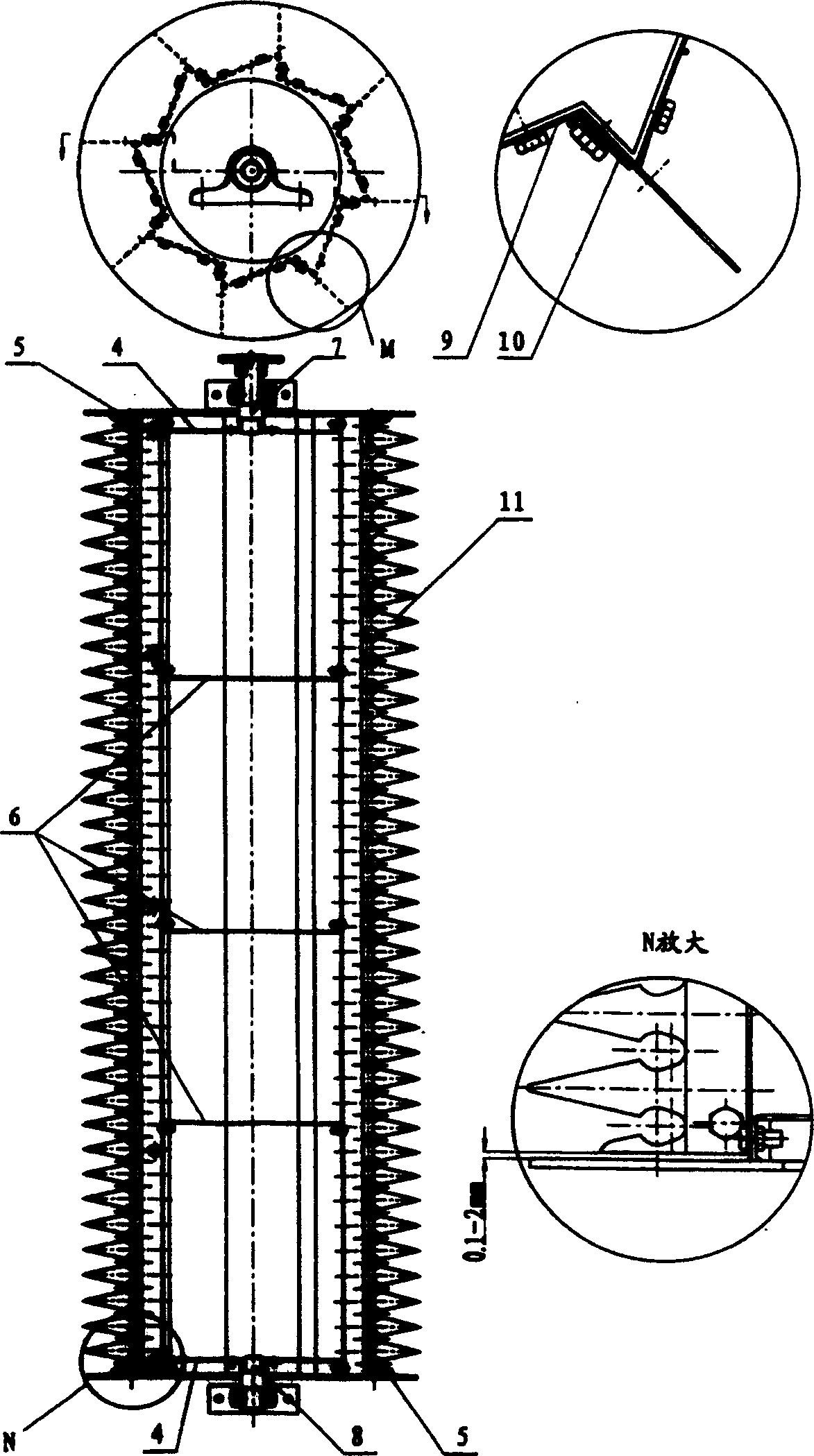

Alternate absorbing core of staggered horizontal tube bundles and ripple screen mesh layer

InactiveCN104676975ALarge mass transfer areaReduce splash lossEnergy efficient heating/coolingClimate change adaptationWave shapeEngineering

The invention discloses an alternate absorbing core of staggered horizontal tube bundles and ripple screen mesh layers. The ripple screen mesh layers are inserted among horizontal tube bundles of the staggered horizontal tube bundles; the cross-section shapes of the ripple screen mesh layers are in a trapezoidal wave shape, and the adjacent ripple screen mesh layers are symmetrical relative to the clamped horizontal tube bundles; the upper edge and lower edge of the ripple screen mesh layer trapezoidal wave are respectively arranged on the lower part of an upper-layer heat transferring tube and the upper part of a lower-layer heat transferring tube of the ripple screen mesh layer trapezoidal wave; the folding line direction of the ripple screen mesh layer trapezoidal wave and the direction of the heat transferring tubes are the same; the ripple pitch of the trapezoidal wave is equal to the horizontal tube center distance of each horizontal tube bundle; a formed liquid membrane orderly passes through an alternate caloric transmitting structure of the horizontal tube bundles and the ripple screen mesh layers. The alternate absorbing core has the advantages that the absorbing area of the absorbing core is enlarged, furthermore the solution mixing is promoted, and the solution surface is kept continuing relatively strong in absorbing driving power, so that en effect that a reinforced solution absorbs cryogen steam is realized.

Owner:SOUTHEAST UNIV

Process method for converter smelting of weathering resistant steel

ActiveCN104561436AReduce thermal efficiencyHigh phosphorus contentManufacturing convertersMelting tankChemical composition

The invention discloses a process method for converter smelting of weathering resistant steel. The process comprises the following steps: 1) after smelting carbon steel by a converter, conveying steel slag treated by hot slag or drum slag as a slag auxiliary to an overhead bunker of the converter for later use, wherein the steel slag of the converter comprises the following chemical components in percentage by weight: 56% of CaO, 18% of SiO2, 0.3% of P2O5, 12% of TFe, 9% of MgO and 4.7% of other components; 2) using carbon-containing magnesium balls produced by the company Henglongxiang, wherein the magnesium balls comprise the following chemical components in percentage by weight: 15% of CaO, 12% of SiO2, 55% of MgO and 18% of C; 3) smelting by the converter according to a normal smelting program: namely, after adding molten iron steel scrap and before blowing by an oxygen lance, adding 60kg / ton steel of abandoned cold slag of the converter, and adding 3kg / ton steel of magnesium balls after decarburizing reaction to inhibit phosphorus in a molten bath from being oxidized into slag; and 4) before converter blowing end point, adding 5kg / ton steel of magnesium balls to press the slag, tapping after 3 minutes, and reducing phosphate in steel slag by using intermediate carbon by using the magnesium balls, so that phosphate enters molten steel.

Owner:XINJIANG BAYI IRON & STEEL

Novel high-adhesion environment-friendly pesticide adjuvant as well as application and preparation method thereof

ActiveCN112825854AReduce rebound rateIncrease profitBiocideAnimal repellantsCarboxyl radicalNicotiana tabacum

The invention discloses a novel high-adhesion environment-friendly pesticide adjuvant as well as application and a preparation method thereof. The preparation method comprises the following steps: preparing an organic silicon emulsion by using hydrogen-containing silicone oil and acrylic acid through hydrosilylation, uniformly mixing an agricultural antibacterial agent ethylicin with the organic silicon emulsion, adding a dilute acetic acid solution of chitosan into the emulsion, and carrying out anion-cation crosslinking by using amino groups on the chitosan and carboxyl groups on the nontoxic and harmless organic silicon emulsion to achieve physical embedding of pesticide molecules, so as to form the chitosan / organic silicon composite micelle with a drug-loaded inner core. The pesticide adjuvant has a good high-adhesion function, can be quickly spread on tobacco leaves, greatly reduces the springback effect in the spraying process, effectively improves the utilization rate of a pesticide, and reduces the pollution of the pesticide falling into the soil to the soil environment. In addition, the preparation method of the pesticide adjuvant is simple, the pesticide adjuvant can be effective for multiple times after one-time pesticide application, the pesticide cost is effectively reduced, more importantly, the environmental pollution is reduced, and the green development concept is met.

Owner:HANGZHOU NORMAL UNIV QIANJIANG COLLEGE

A tool for filling liquid electrolyte in an electrolyzer

A tool for filling liquid electrolyte in an electrolytic tank, including a chute and a chute cover covering the top of the chute. The baffle plate and the rear side baffle plate are composed of a slide pipe along the axis of the bottom plate in the tank shell. A pair of hooks are respectively provided at the front and rear ends of the left and right baffle plates. The left side baffle plate between the two hooks There are vertical pipes at intervals on the board. The chute cover is composed of left and right cover plates. The two cover plates are connected by a connecting pipe and arranged symmetrically relative to the connecting pipe. The two cover plates form an included angle, 60°≤the The included angle is less than or equal to 150°. There are vertical support rods at intervals on the left side of the left cover plate. The distance between the two support rods is equal to the distance between the two pipes. The two support rods are located in the two pipes. Advantages: It reduces the splash loss of liquid electrolyte, avoids the burning of the gantry column and insulating plate of the electrolyzer, and ensures the safety of the personnel involved in the start-up of the electrolyzer on site.

Owner:ZHENGZHOU FAXIANG ALUMINUM IND

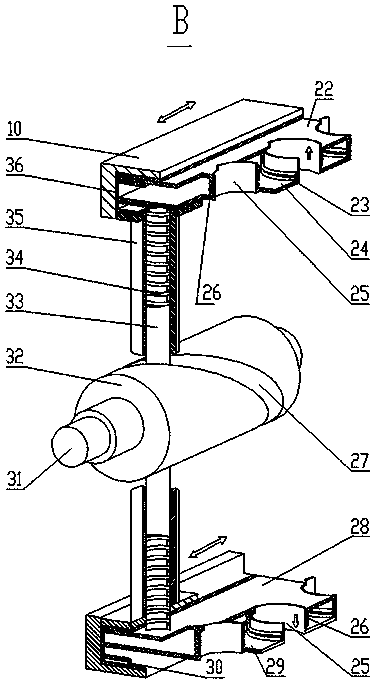

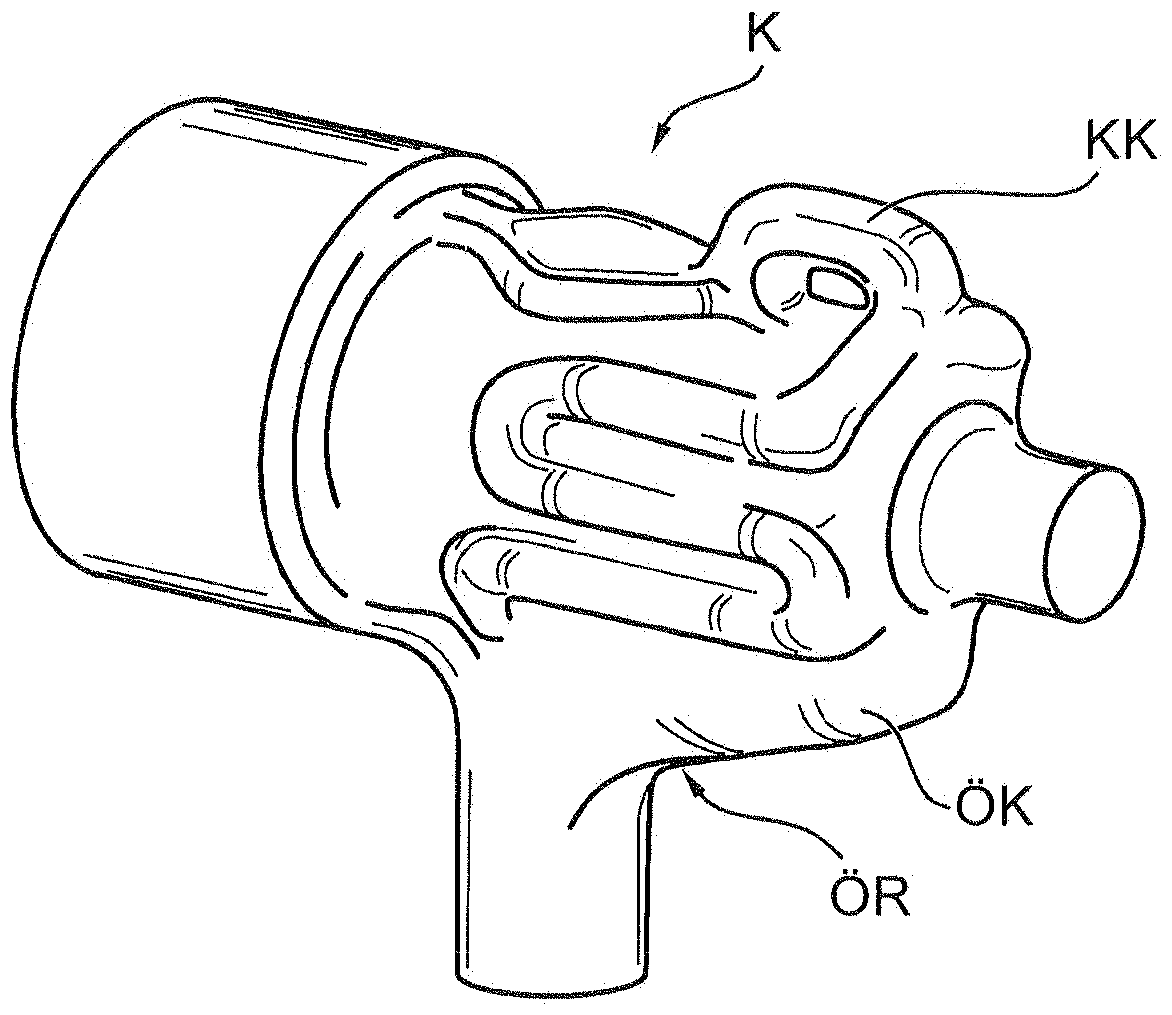

Drive assembly with lubricant reservoir

PendingCN112196978AReduce power lossLess quantityFluid actuated clutchesToothed gearingsActuatorControl theory

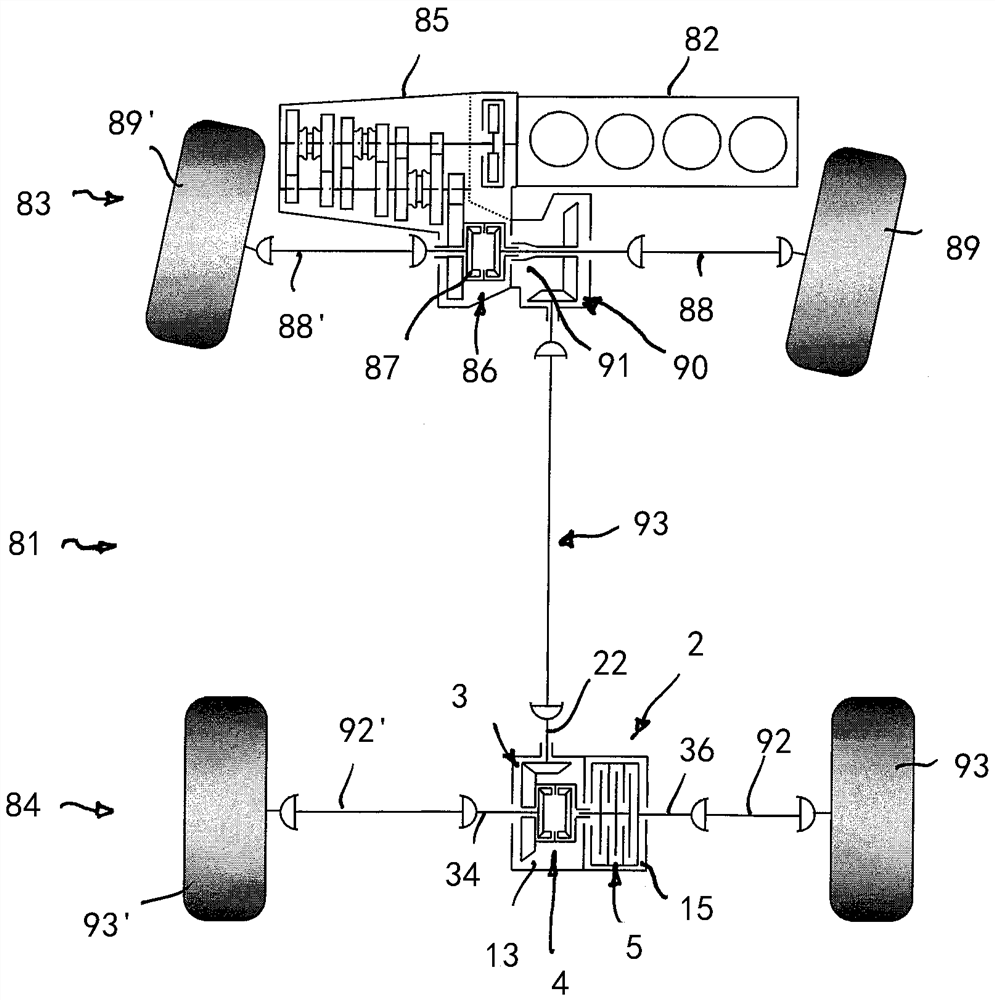

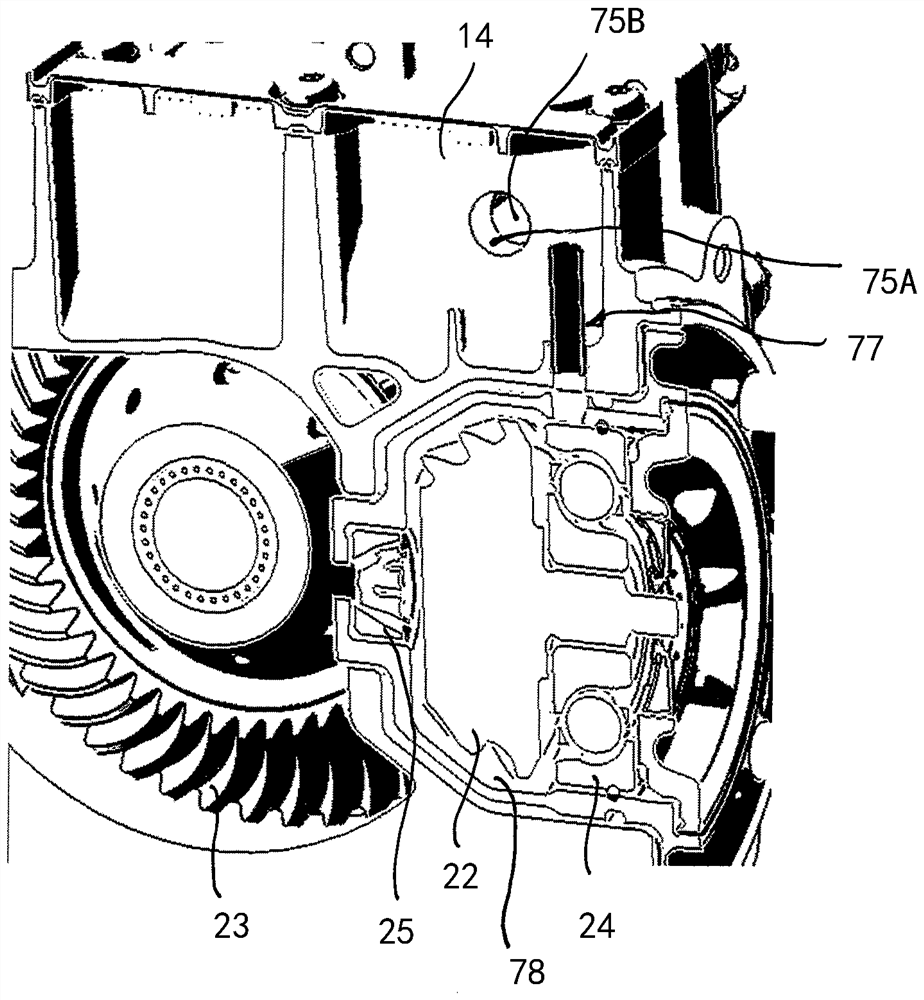

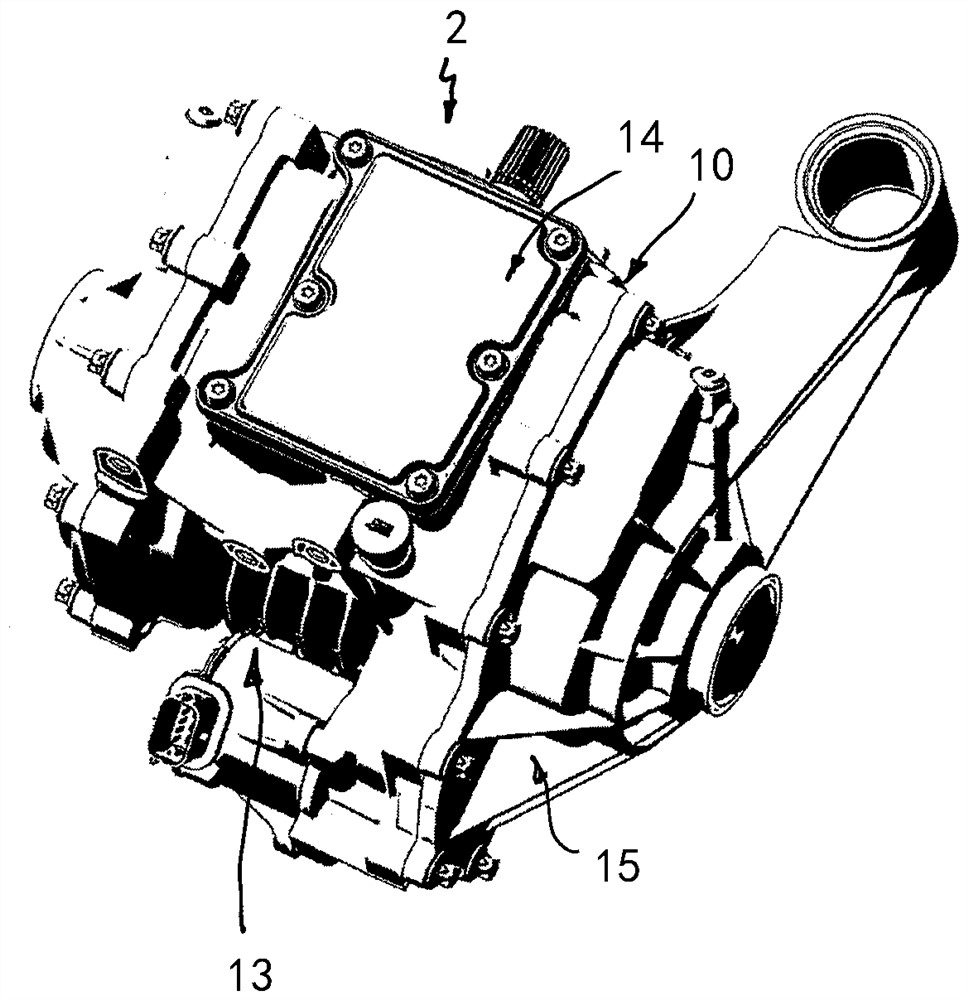

The invention relates to a drive assembly for a drive train of a motor vehicle, comprising: a transmission (3); a clutch (5); an actuator (8) for controlling the clutch (5), wherein the actuator (8) comprises an actuating element (9) acting on the clutch (5) to set a transmittable torque; a housing (10) having a transmission receiving chamber (13), a reservoir (14) and a clutch receiving chamber (15), in which lubricant is delivered from at least one of the transmission receiving chamber (13) and the clutch receiving chamber (15) into the reservoir (14) due to rotational movement during operation; a valve (19) for controlling the flow of lubricant from the reservoir (14) to the transmission receiving chamber (13) and / or to the clutch receiving chamber (15), the valve (19) being operativelyconnected in a manner to the actuating element (9) of the actuator (8), the valve (19) opens when the clutch (5) is actuated and closes when the clutch (5) is not actuated.

Owner:GKN AUTOMOTIVE INC

Alternate absorbent core with forked horizontal tube bundles and corrugated wire mesh layers

InactiveCN104676975BLarge mass transfer areaReduce splash lossEnergy efficient heating/coolingClimate change adaptationWave shapeEngineering

The invention discloses an alternate absorbing core of staggered horizontal tube bundles and ripple screen mesh layers. The ripple screen mesh layers are inserted among horizontal tube bundles of the staggered horizontal tube bundles; the cross-section shapes of the ripple screen mesh layers are in a trapezoidal wave shape, and the adjacent ripple screen mesh layers are symmetrical relative to the clamped horizontal tube bundles; the upper edge and lower edge of the ripple screen mesh layer trapezoidal wave are respectively arranged on the lower part of an upper-layer heat transferring tube and the upper part of a lower-layer heat transferring tube of the ripple screen mesh layer trapezoidal wave; the folding line direction of the ripple screen mesh layer trapezoidal wave and the direction of the heat transferring tubes are the same; the ripple pitch of the trapezoidal wave is equal to the horizontal tube center distance of each horizontal tube bundle; a formed liquid membrane orderly passes through an alternate caloric transmitting structure of the horizontal tube bundles and the ripple screen mesh layers. The alternate absorbing core has the advantages that the absorbing area of the absorbing core is enlarged, furthermore the solution mixing is promoted, and the solution surface is kept continuing relatively strong in absorbing driving power, so that en effect that a reinforced solution absorbs cryogen steam is realized.

Owner:SOUTHEAST UNIV

Asynchronous air-sweeping type flexible bionic retractable standing grain moving device

The invention discloses an asynchronous air-sweeping type flexible bionic retractable standing grain moving device. According to the device, a machine frame is located outside, bionic standing grain moving mechanisms are evenly distributed outside the machine frame in the radial direction, a fan mechanism is located inside the machine frame, a transmission mechanism is located at the left end of the machine frame, threaded holes are distributed in a base of the machine frame, each bionic standing grain moving mechanism is formed by a positioning bolt, a spring and a bionic standing grain moving plate, stretching and retracting of the bionic standing grain moving mechanisms are achieved through the springs, an air inlet is formed in front of a fan cover, an air outlet is formed behind the fan cover, a fan belt wheel is fixed on the left half axle through a flat key, a standing grain moving belt wheel is mounted on the outer ring of a bearing and is connected with a left baffle through a long bolt, and then the bionic standing grain moving mechanisms and the fan mechanism can rotate coaxially at different speeds. The device has the advantages that stand grain moving contact impact is small, the stand grain moving height and feeding depth are continuously adjustable, loss of grains of crops is small during stand grain moving, damage to the surfaces of the grains of crops is small, the structure is simple and compact, and overall efficiency of stand grain moving operation is high.

Owner:JILIN UNIV

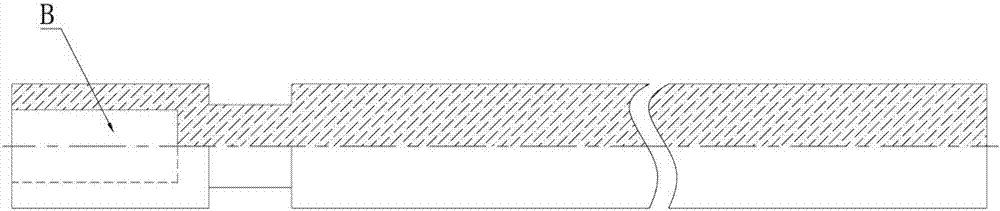

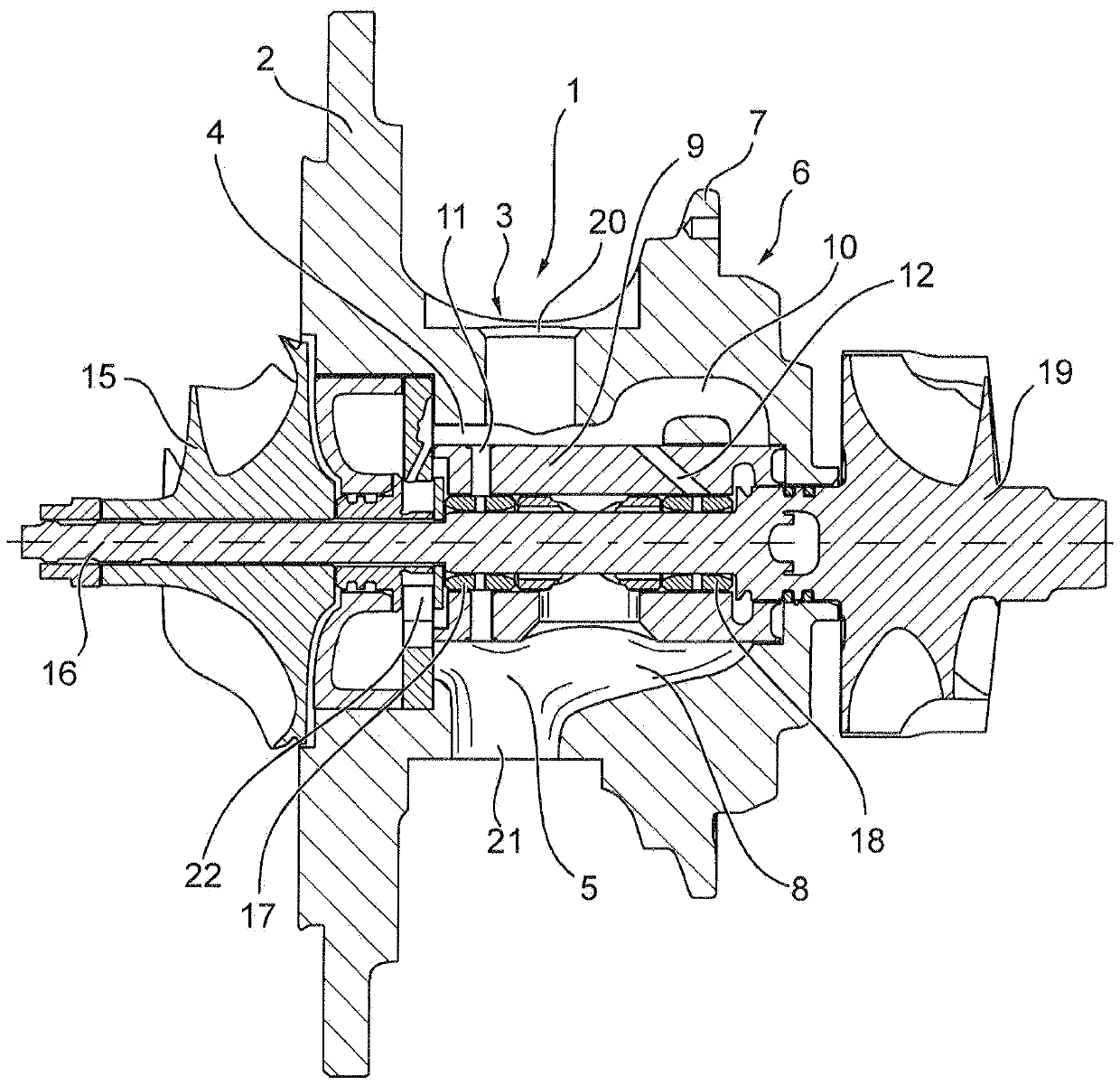

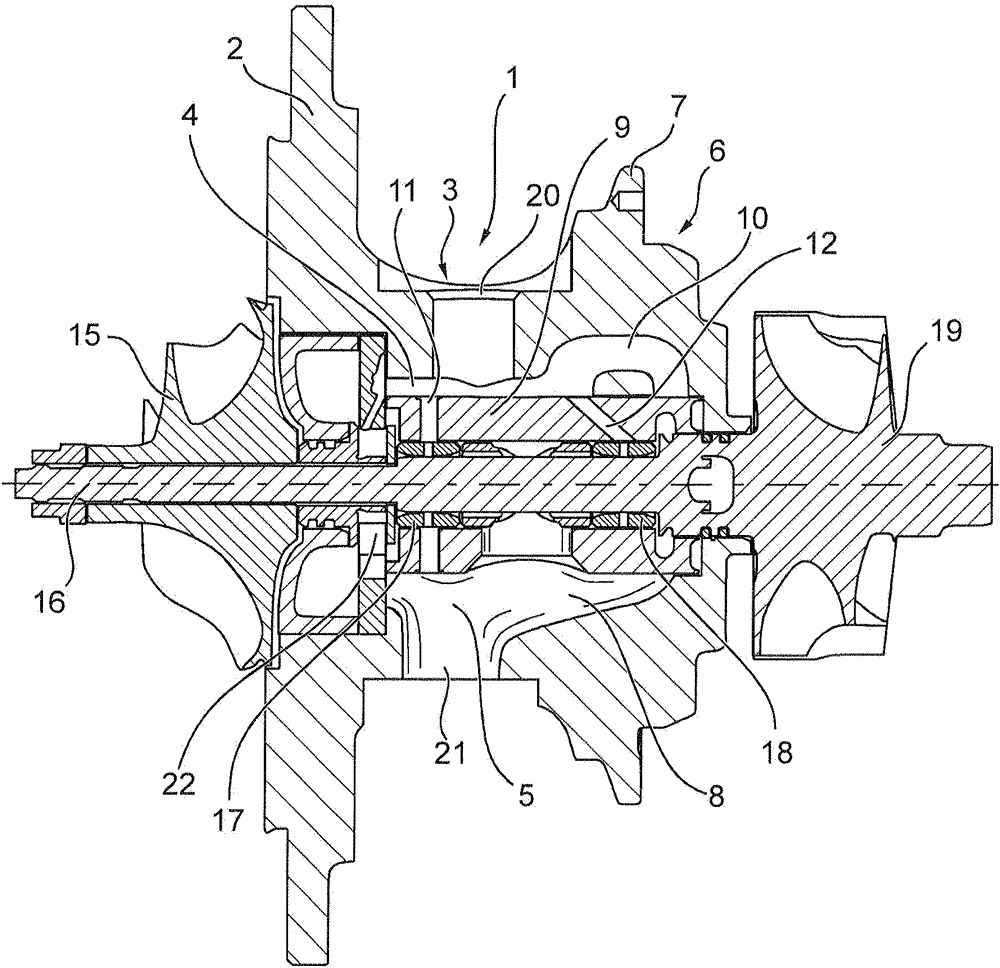

Bearing housing for exhaust turbocharger

InactiveCN105114137BImprove cooling effectEffective isolationMachines/enginesEngine componentsTurbochargerOil cooling

The invention relates to a bearing housing (1) of an exhaust-gas turbocharger, the bearing housing having: a compressor-side housing flange (2); a central housing section (3), the central The housing section is integrally connected to the housing flange (2) and a first part section (4) of an oil chamber (5) is arranged in the central housing section, the oil chamber having a oil inlet (20) and an oil outlet (21); and has a turbine side housing section (6) with a turbine side housing flange (7) and A second subsection (8) of the oil chamber (5) is arranged in the side housing sections, wherein the central housing section and the turbine side housing sections (3, 6) are equipped with an oil cooling duct (13; 13').

Owner:BORGWARNER INC

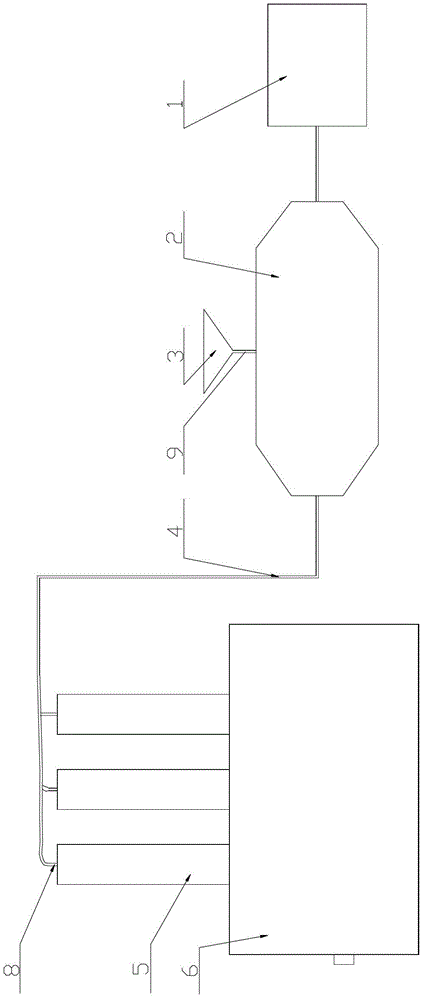

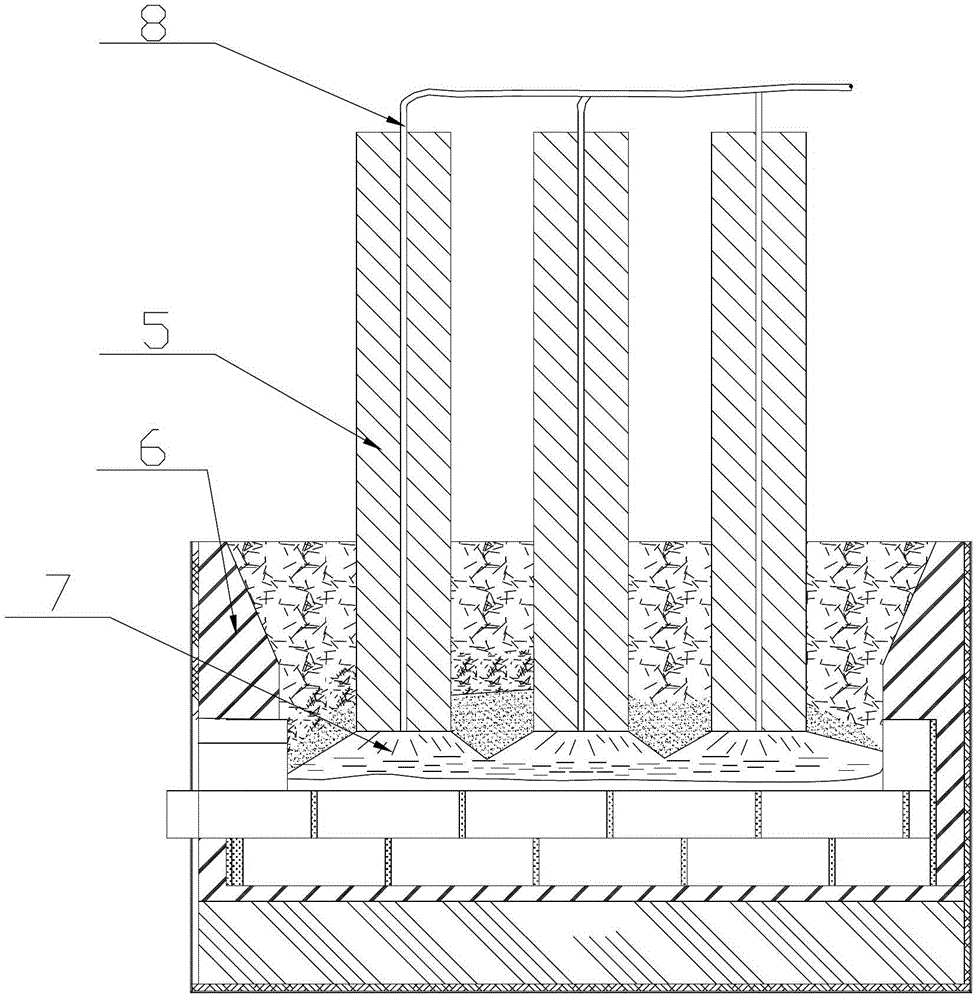

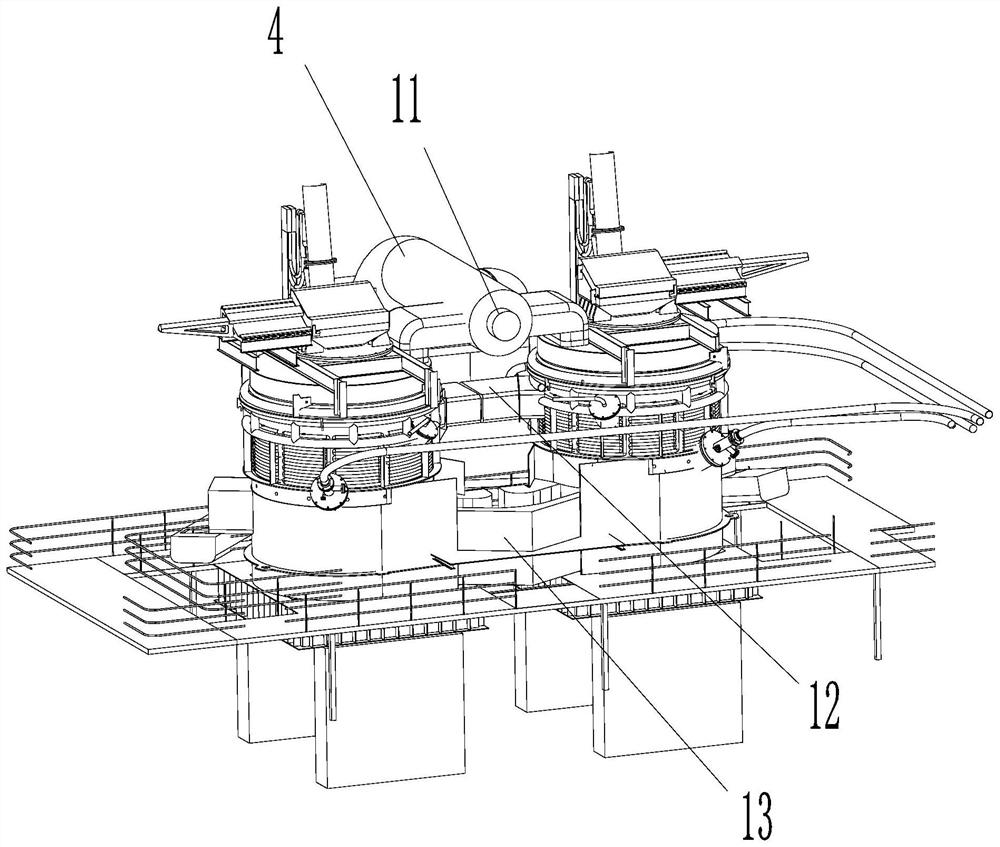

A kind of in-furnace heat exchange type electric arc metallurgy equipment for smelting various special alloys

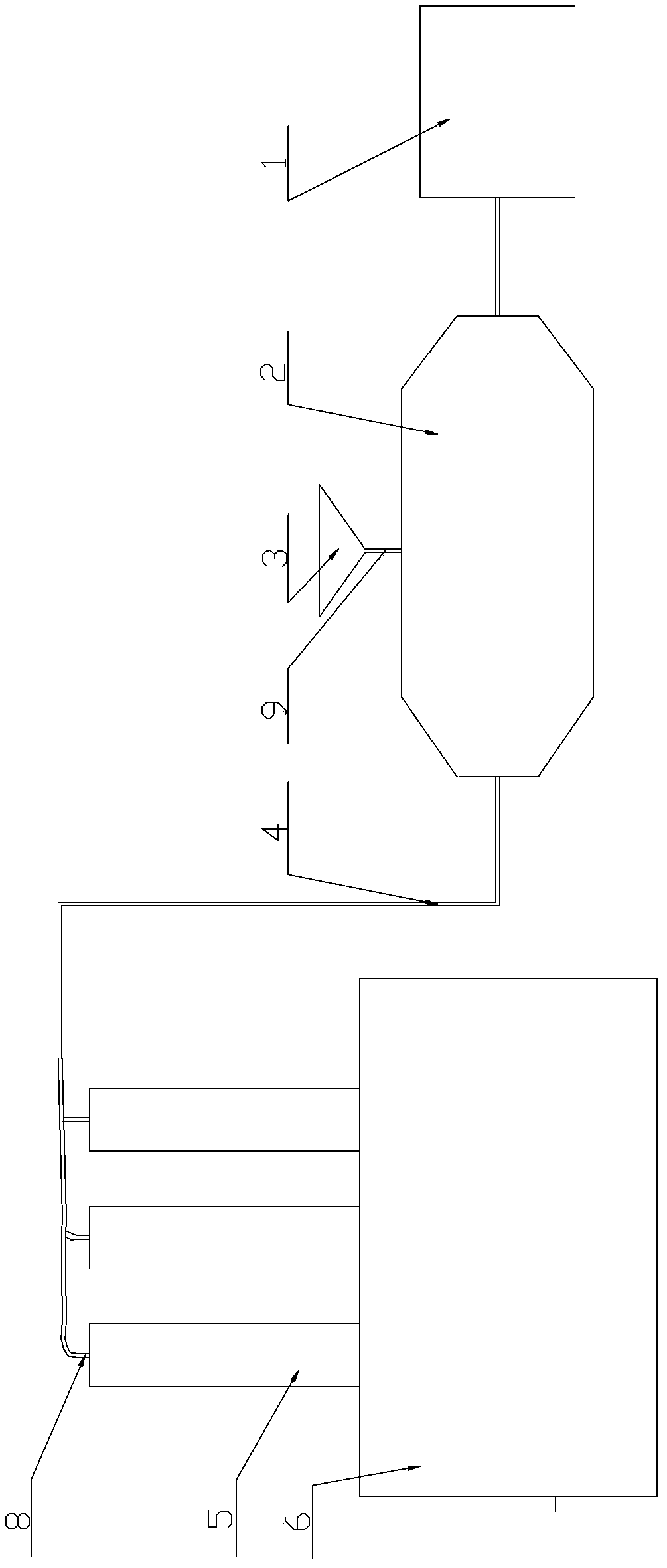

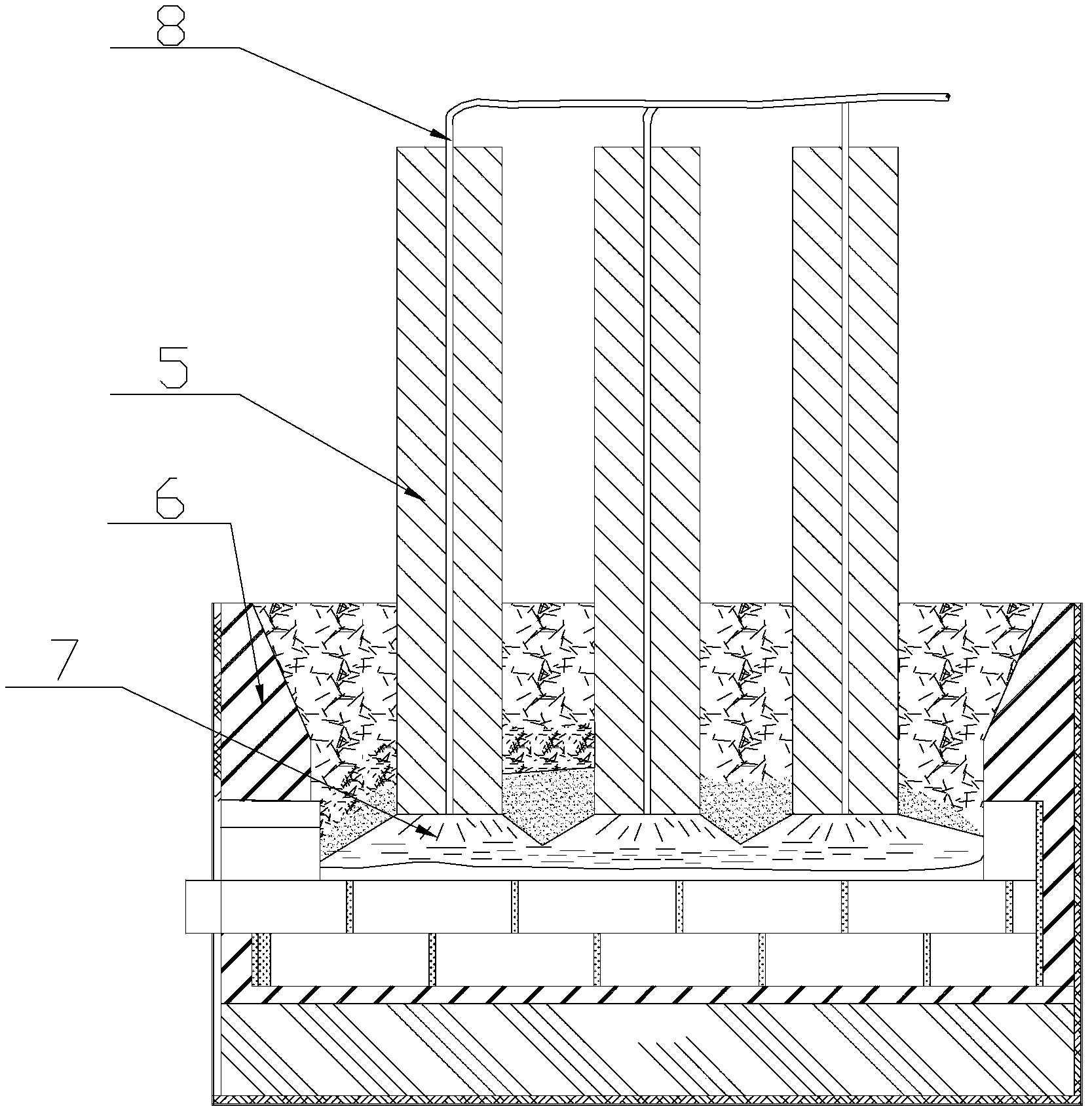

The invention relates to the technical field of industrial metallurgical smelting equipment, in particular to furnace heat exchange type electric arc metallurgy equipment for smelting various special alloys. The equipment comprises an air compressor (1), a mixing cylinder (2), a feed hopper (3), a main pipe (4), hollow electrodes (5), an electric furnace (6), electric arc areas (7), branch pipes (8) and a feeding pipe (9). The equipment is characterized in that one end of the mixing cylinder (2) is fixedly connected with a smelting device through the main pipe (4) while the other end is connected with one end of the air compressor (1) fixedly, one side of the mixing cylinder (2) is fixedly connected with the feed hopper (3) through the feeding pipe (9), the smelting device comprises the hollow electrodes (5), the electric furnace (6), the electric arc areas (7) and the branch pipes (8), and one end of each hollow electrode (5) is in through connection with the main pipe (4) through the corresponding branch pipe (8).

Owner:甘肃山丹腾达西铁冶金有限责任公司

Bearing housing of an exhaust-gas turbocharger

InactiveCN105114137AEffective isolationImprove sealingMachines/enginesEngine componentsTurbochargerEngineering

A bearing housing (1) of an exhaust-gas turbocharger, having a compressor-side housing flange (2), a central housing section (3) which is integrally connected to the housing flange (2) and in which is arranged a first partial section (4) of an oil chamber (5) which has an oil inlet (20) and an oil outlet (21), and a turbine-side housing section (6) which has a turbine-side housing flange (7) and in which is arranged a second partial section (8) of the oil chamber (5). The central and turbine-side housing sections (3, 6) are provided with an oil cooling duct (13; 13′).

Owner:BORGWARNER INC

Power-shift transmission for a commercial vehicle

InactiveCN101415967BLarge installation spaceSave installation spaceToothed gearingsTransmission elementsGear wheelEngineering

In a load shift transmission for a utility vehicle having a transmission input shaft, a split group, a main group and a range group, a dual clutch with two input shafts, a main shaft and a countershaft with input constants including loose gear wheels, one loose gear wheel of an input constant is selectively rotationally fixedly connectable by means of shift elements to either one of the input shafts which can in each case be coupled by means of clutches (K1,K2) to the main transmission input shaft, the countershaft can be driven by one of three input constants with power being transmitted via the countershaft in all forward gears with the exception of a direct gear. The arrangement provides, with a simple design, for the possibility to carry out sequential shifts and multiple up-shifts and multiple down-shifts without an interruption in traction force.

Owner:DAIMLER AG

Furnace heat exchange type electric arc metallurgy equipment for smelting various special alloys

InactiveCN104110957AAvoid enteringReduce pollutionLighting and heating apparatusElectric arc furnaceAlloy

The invention relates to the technical field of industrial metallurgical smelting equipment, in particular to furnace heat exchange type electric arc metallurgy equipment for smelting various special alloys. The equipment comprises an air compressor (1), a mixing cylinder (2), a feed hopper (3), a main pipe (4), hollow electrodes (5), an electric furnace (6), electric arc areas (7), branch pipes (8) and a feeding pipe (9). The equipment is characterized in that one end of the mixing cylinder (2) is fixedly connected with a smelting device through the main pipe (4) while the other end is connected with one end of the air compressor (1) fixedly, one side of the mixing cylinder (2) is fixedly connected with the feed hopper (3) through the feeding pipe (9), the smelting device comprises the hollow electrodes (5), the electric furnace (6), the electric arc areas (7) and the branch pipes (8), and one end of each hollow electrode (5) is in through connection with the main pipe (4) through the corresponding branch pipe (8).

Owner:甘肃山丹腾达西铁冶金有限责任公司

Combine combing barrel

The invention discloses a combing cartridge for combine-harvesters which mainly comprises a fender disc, an intermediate disc, a shaft and a coxcomb, the fender discs are arranged on the two sides, the adjacent coxcombs form a sealed barrel with closing plate, disc and intermediate disc, the tooth outline of the coxcomb is triangular, THE adjacent teeth form a heat shaped combing volume through two semi-circles and a trapezoid of variation in size.

Owner:TAIZHOU CHANGFA AGRI EQUIP

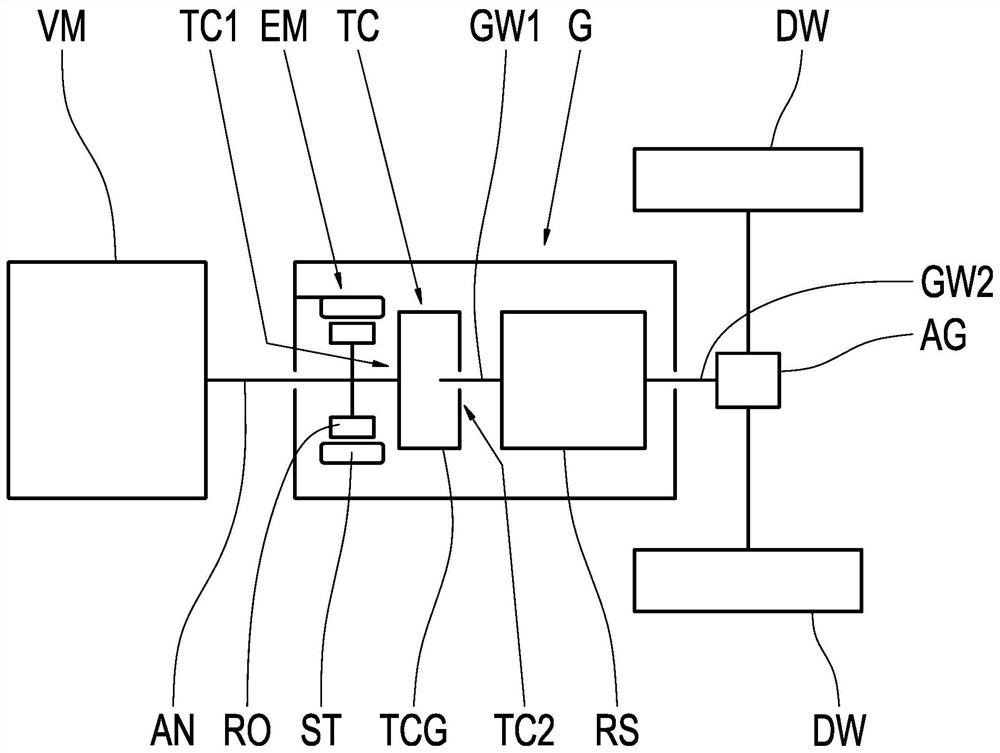

Hybrid Drive Unit and Drive Train for Motor Vehicle

PendingCN112406517AAvoid cloggingIncrease contact timeHybrid vehiclesGearboxesElectric machineControl theory

The invention relates to a hybrid drive unit (HY, G) for a motor vehicle, and the hybrid drive unit (HY, G) includes a housing (GG), in which a torque converter (TC) and an electric machine (EM) are accommodated. The electric machine (EM) and the torque converter (TC) are arranged directly next to each other such that the electric machine (EM) is arranged at a first face end (TC1) of the torque converter housing (TCG). An oil guide shell (LS) at least partially encompasses a section of the torque converter (TC). The oil guide shell (LS) has an L-shaped cross-section including a first section (LS1) and a second section (LS2) and is arranged in such that the first section (LS1) partially encompasses a second face end (TC2) of the torque converter housing (TCG) and the second section (LS2) partially encompasses a circumferential surface of the torque converter housing (TCG).

Owner:ZF FIEDRICHSHAFEN AG

A method for modifying molten steel slag with double molten pool furnace

The invention discloses a method for modifying molten steel slag in a double molten pool furnace. The method includes: providing a double molten pool furnace: the furnace body of the double molten pool furnace contains two molten pools, and the two molten pools pass through the The furnace body is connected to the flue, and the middle high-temperature flue is arranged between the two melting pools. One end of the middle high-temperature flue is connected to the powder collection system, and the other end is connected to one of the two melting pools through the flue gas guiding switching valve; The air-guided switching valve uses the two melting pools alternately as an oxidation melting pool and a reduction melting pool, and uses the oxidation melting pool and the reduction melting pool to realize comprehensive treatment of steel slag, zinc-containing dust and symbiotic ores that are difficult to dissociate. This method can modify steel slag into iron-making reduction slag to be widely used as concrete admixture, and can remove the alkali metal harmful to smelting in the dust removal dust of steel mills, and also provides a kind of refractory slag existing in nature. Melt dissociation method of symbiotic ore.

Owner:MOUNTOP GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com