Technology for preventing water drop splashing of vertical current force cooling tower

A cooling tower, flow technology, applied in the direction of water shower cooler, direct contact heat exchanger, heat exchanger type, etc., can solve the problems of fading, easy deformation, splashing water droplets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

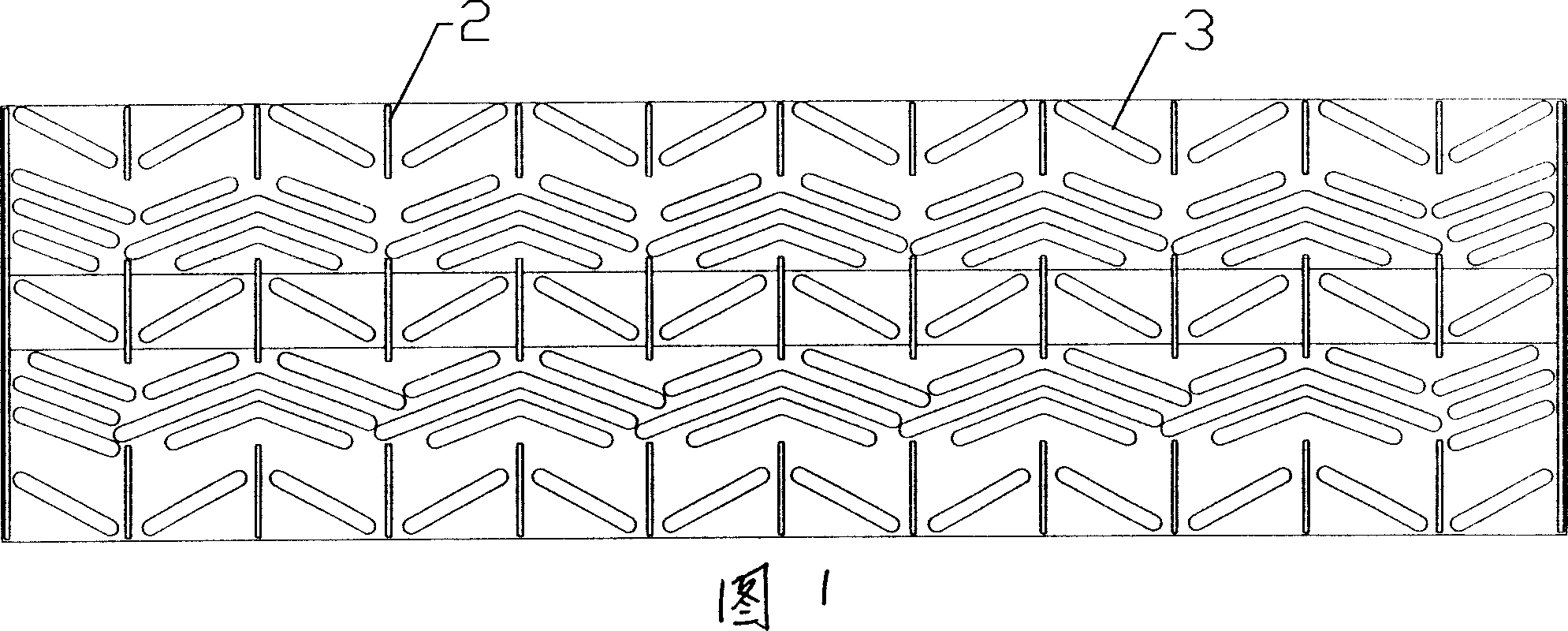

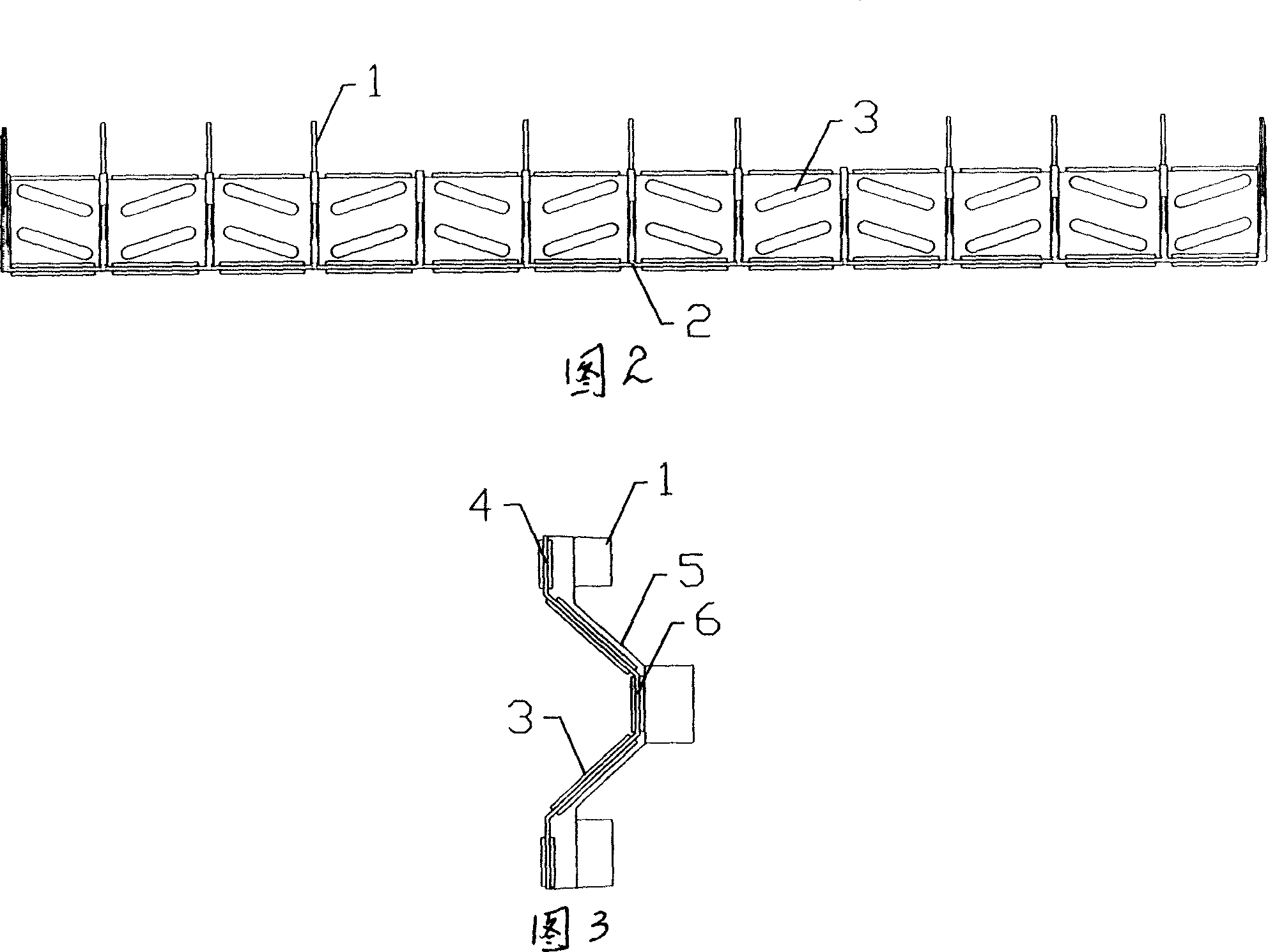

[0009] A drip-proof and splash-proof technology for a vertical flow cooling tower, which mainly includes the following steps: A. Provide a water retaining member so that the upper and lower sections of the main body are upright sections, which are connected with a backward bending section , the middle is an upright section; B. The surface of the body provides a kind of insertion hole, and the other side provides a positioning orifice plate that matches the insertion hole. The structure of the water stop component of the vertical flow cooling tower manufactured by the present invention will be described in further detail below in conjunction with the accompanying drawings. In the figure, the water stop component of the vertical flow cooling tower is mainly composed of a body, which adopts a five-fold design. The upper and lower sections of the body are upright sections 4, which are connected with a rearward angle The bent section 5 has an upright section 6 in the middle, one su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com