A method for modifying molten steel slag with double molten pool furnace

A molten, converter steel slag technology is applied in the modification treatment under reducing atmosphere conditions, and the steel slag is in the field of oxidation, which can solve the problems such as limiting the use of steel-making waste slag, and achieve the effect of expanding the utilization of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

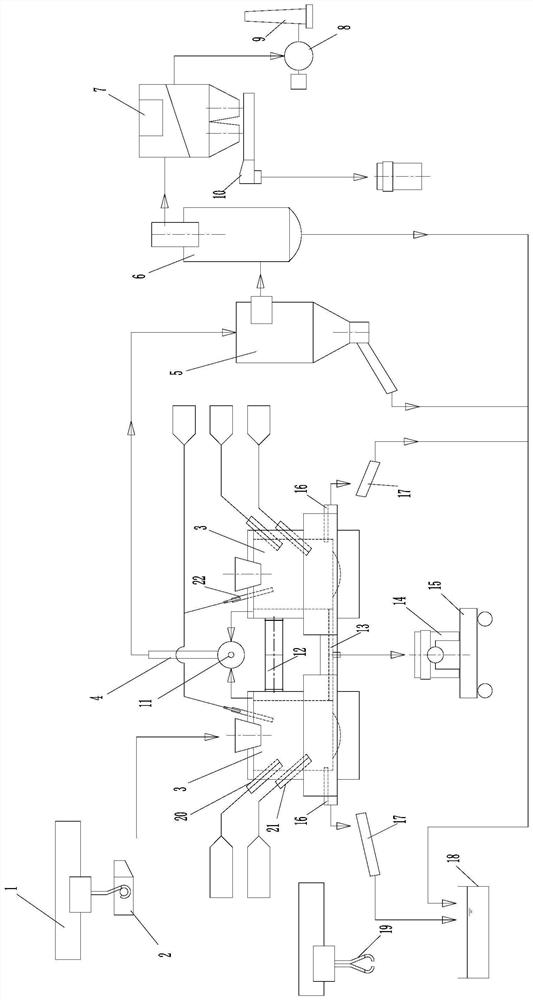

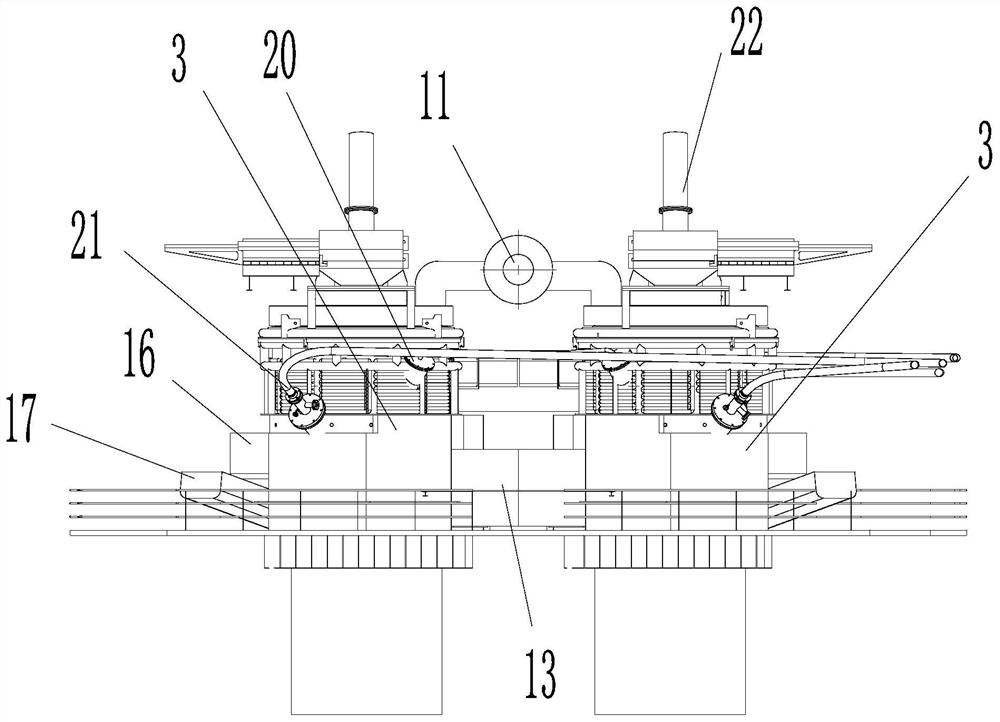

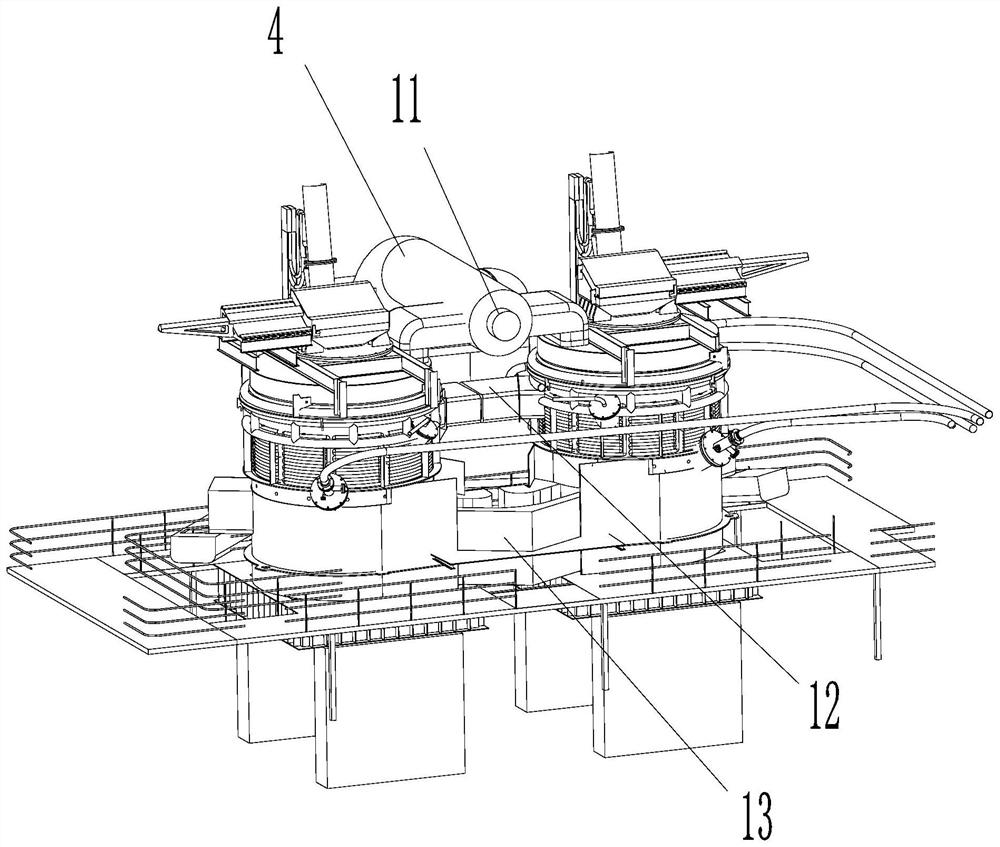

[0033] The present invention will be further explained below in conjunction with the accompanying drawings.

[0034] Such as Figures 1 to 3 Shown, a kind of double melting pool furnace modification method of the present invention handles the method for hot molten steel slag, and this method comprises:

[0035] Provide double molten pool furnace: the furnace body of the double molten pool furnace contains two molten pools, and the top of the two molten pools is respectively equipped with a furnace cover that can be opened and closed. The two molten pools are connected through the furnace connecting flue on the furnace body. The connection port between the molten pool and the furnace body is arranged along the tangential direction of the inner wall of the molten pool, and an intermediate high-temperature flue is arranged between the two molten pools. One end of the intermediate high-temperature flue is connected to the powder collection system, and the other end is connected th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com