Drive assembly with lubricant reservoir

A technology of transmission components and storage, applied to components with teeth, transmission parts, transmissions, etc., can solve problems such as loss, and achieve the effect of reducing splash loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

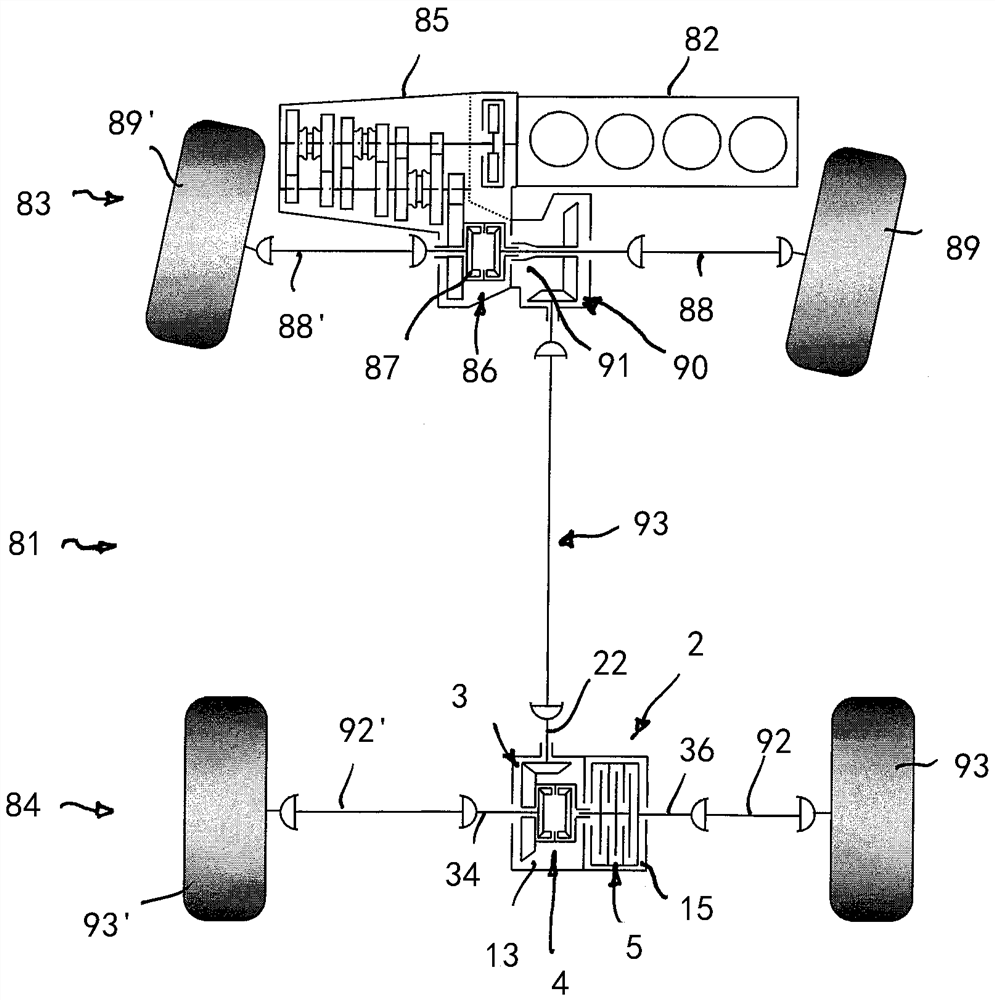

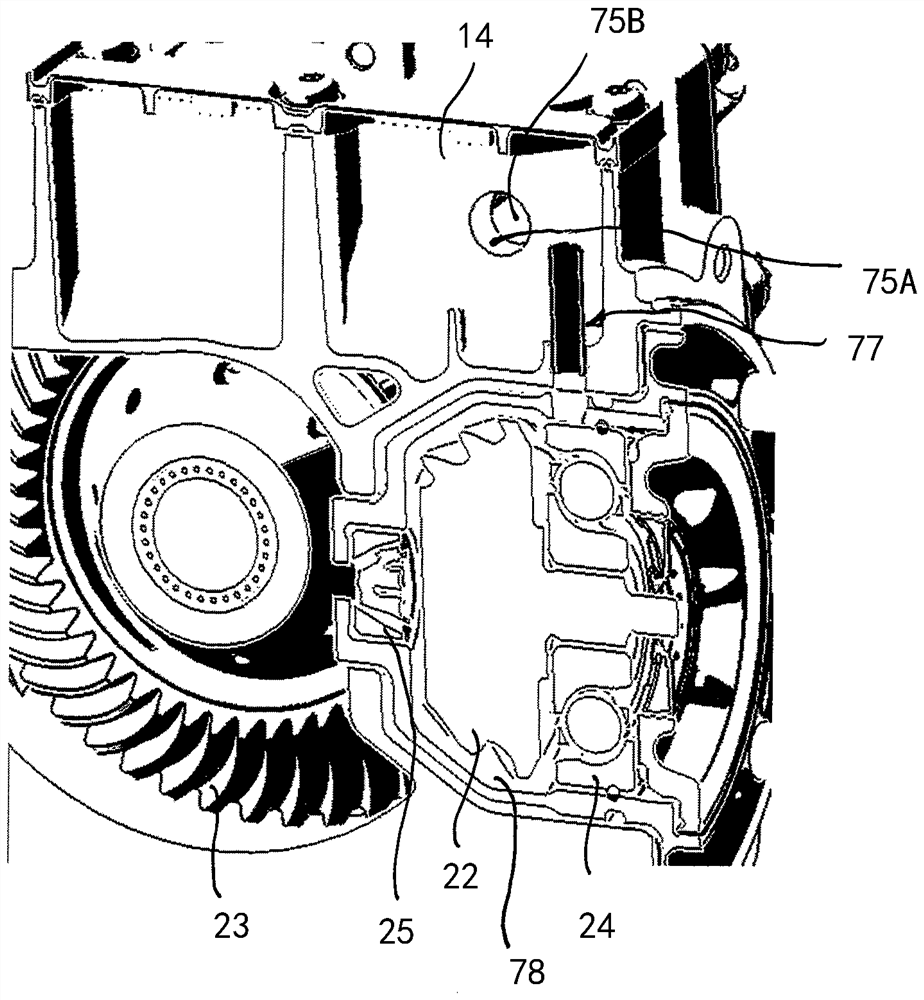

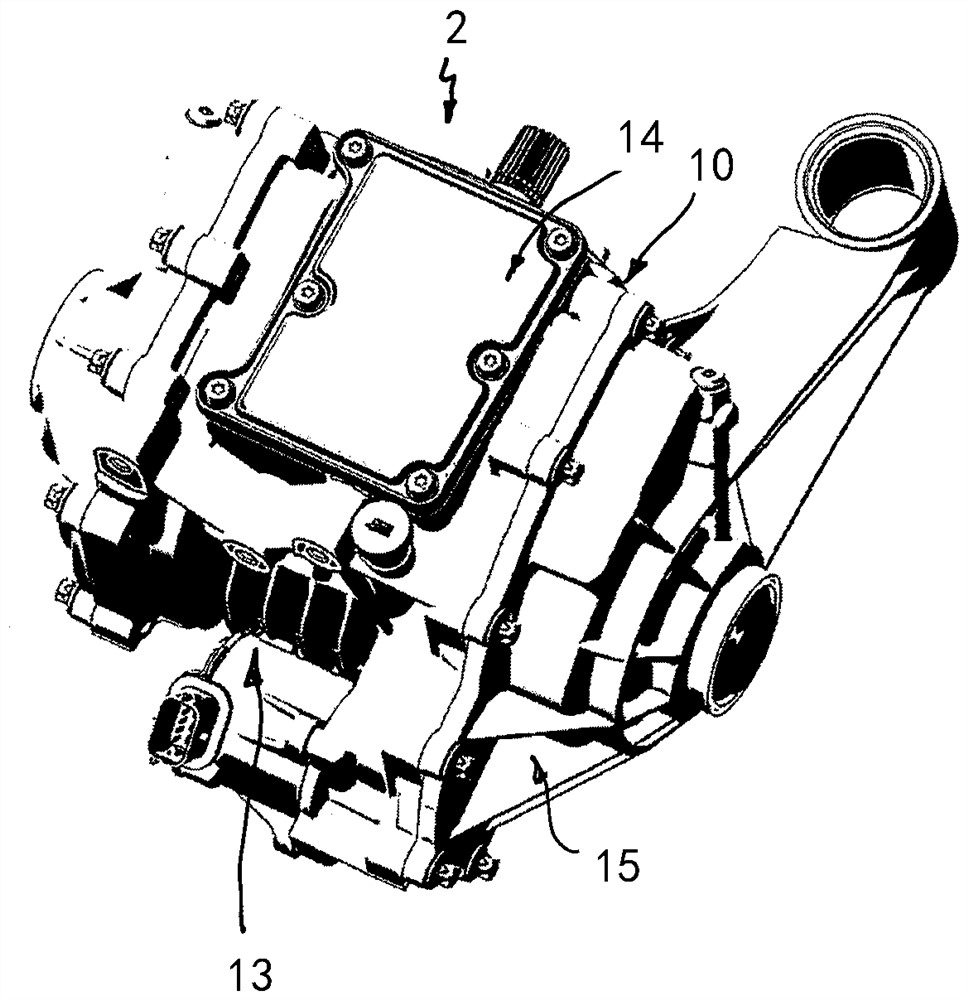

[0051] Figures 1 to 6, which are described together below, show a drive assembly 2 according to the invention for a drive train of a motor vehicle. In the present embodiment, the transmission assembly 2 comprises: a first gear arrangement 3, which can also be designated as a transmission and is designed in particular in the form of an angle transmission; a second gear arrangement 4, which is arranged downstream in the power path , which is optional and is designed here in the form of a differential transmission; and a clutch 5, which is drivingly connected to the first gear unit and the second gear unit, respectively, and is designed for the clutch input portion 6 and the clutch Variable torque transfer between output sections 7. An actuator 8 with an actuating element 9 is provided for controlling the clutch 5 , which acts on the clutch 5 to adjust the torque transmittable between the clutch input part 6 and the clutch output part 7 .

[0052] The transmission assembly 2 als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com