Alternate absorbing core of staggered horizontal tube bundles and ripple screen mesh layer

A technology for absorbing cores and screen layers, applied in the field of alternating absorbing cores, can solve the problems of restricting the performance of the absorbing system, the effect of absorption enhancement is not obvious, and the loss of solution splashing is large, so as to avoid the problem of solution crystallization and reduce splashing Effects of loss and prolongation of flow time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

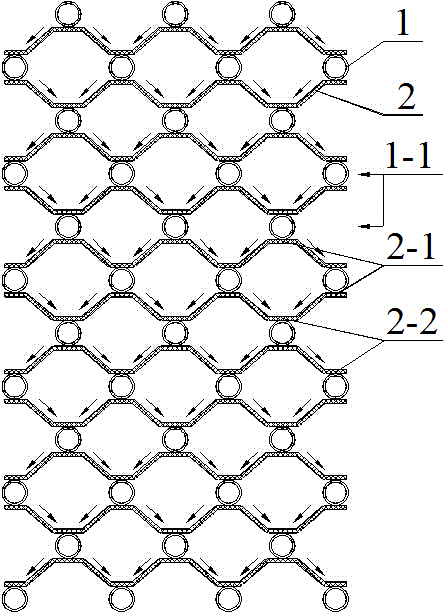

[0013] The embodiment of the present invention is an alternate absorbent core with forked horizontal tube bundles and corrugated wire mesh layers, including forked horizontal tube bundles 1 and corrugated wire mesh layers 2, and forked horizontal tube bundles 1 include horizontal tube rows composed of heat transfer tubes 1-1, the corrugated wire mesh layer 2 is inserted between the horizontal tube rows 1-1 of the forked horizontal tube bundle 1; it is characterized in that: the corrugated wire mesh layer 2 has a trapezoidal wave cross section and adjacent The corrugated screen layer 2 is symmetrical to the horizontal tube row 1-1 between adjacent corrugated screen layers 2, and each corrugated screen layer 2 is clamped between each adjacent horizontal tube row 1-1, and the corrugated screen The upper edge 2-1 of the trapezoidal wave of layer 2 is set under the upper heat transfer tube in the adjacent horizontal tube row 1-1, and the lower edge 2-2 of the trapezoidal wave of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com