A tool for filling liquid electrolyte in an electrolyzer

A liquid electrolyte and electrolytic cell technology, which is applied in the field of aluminum smelting, can solve the problems of reducing insulation level and insulation pouring damage, and achieve the effects of avoiding burning damage, ensuring safety, and reducing splash loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

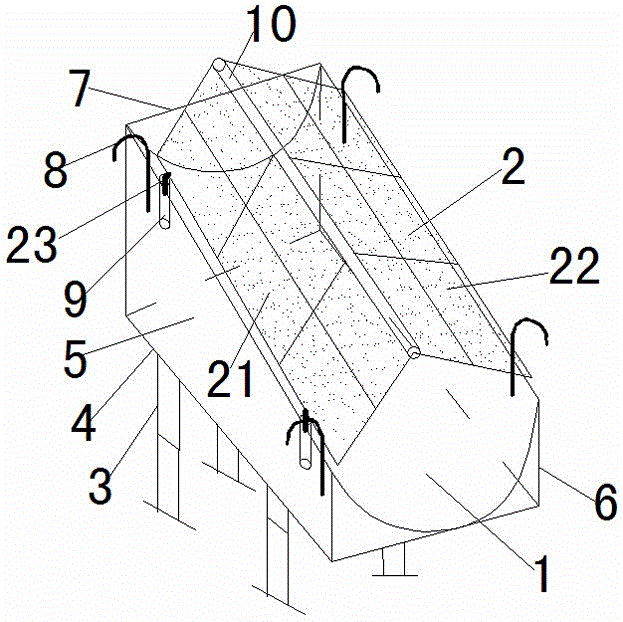

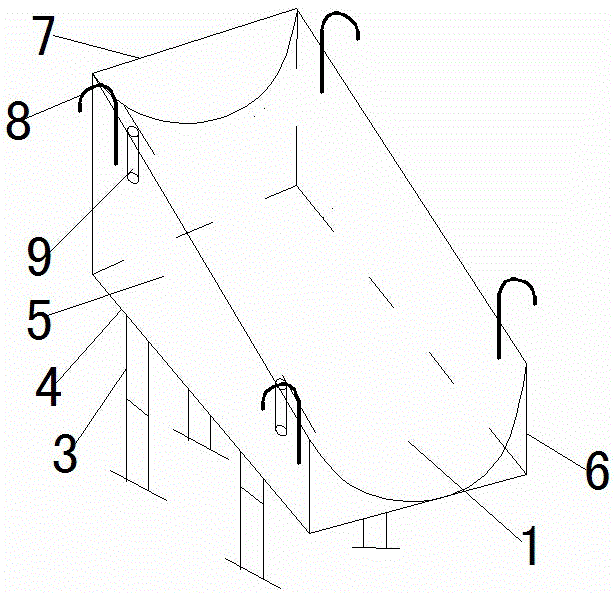

[0014] Such as figure 1 , 2 , 3 and 4, a tool for pouring liquid electrolyte into an electrolytic cell, including a chute and a chute cover 2 covering the top of the chute. The chute includes a chute shell and a chute 1. The bottom plate 4 with the bracket 3, the left side baffle 5, the right side baffle 6 and the rear side baffle 7 are constituted. The trough shell is provided with a slide pipe 1 along the axis direction of the bottom plate 4, the left side baffle 5 and the right side The front and rear ends of the plate 6 are provided with a pair of hooks 8 respectively. The left baffle 5 between the two hooks 8 is provided with a vertical pipe 9 at intervals. The chute cover 2 consists of a left cover 21 and a right The side cover 22 is composed of the left cover 21 and the right cover 22 connected by a connecting tube 10 and arranged symmetrically with respect to the connecting tube 10, and a 60° clamp is formed between the left cover 21 and the right cover 22 At the corner...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com