Double-hole rotary fireproof spray gun

A rotary, refractory technology, used in lighting and heating equipment, furnace components, furnaces, etc., can solve problems such as rotary spray guns that have not yet been found, and achieve the effect of reducing metal splash loss, improving stress distribution, and slowing the floating speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

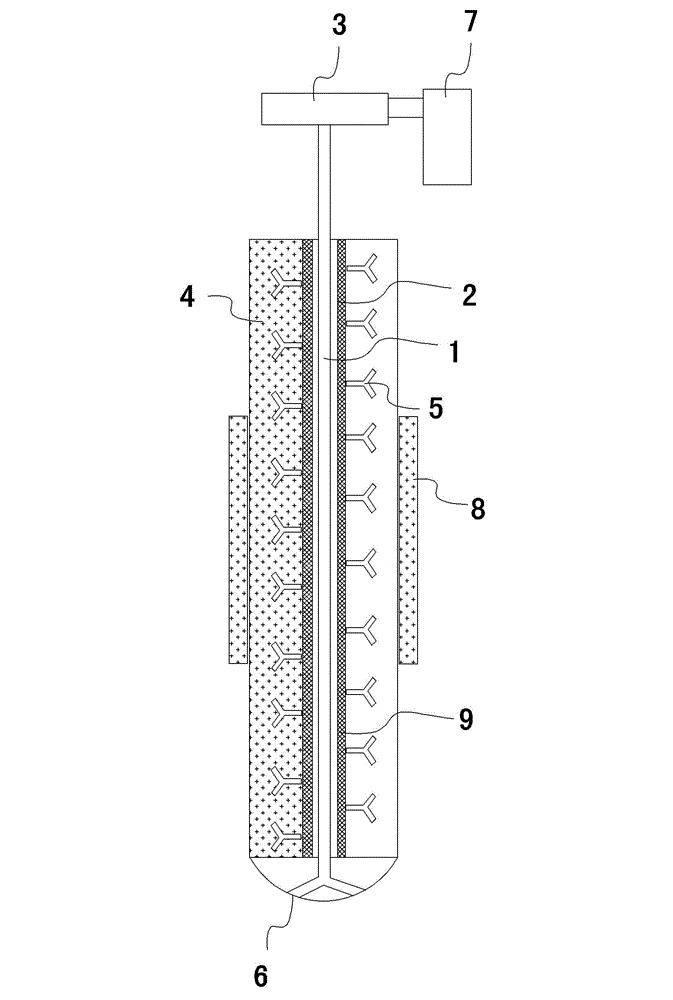

[0014] As shown in the figure, the double-hole rotary refractory spray gun includes a gun body; The blue plate 3; the central nozzle 1 is set in the protective tube 2; the refractory material layer 4 is placed outside the protective tube 2; in the refractory material layer 4, a skeleton 5 is fixed outside the protective tube 2; The lower end of the central nozzle 1 is provided with two tail nozzles 6 ; the output power of the rotating mechanism 7 is transmitted to the flange 3 .

[0015] In order to protect the structure of the bottom of the gun body and prolong the service life of the spray gun, the bottom of the gun body of the present invention can be designed to be hemispherical.

[0016] The gun body of the present invention can be fixed with rotating stirring blades 8, and the number of the rotating stirring blades 8 is four, and they are evenly distributed on the outer wall of the gun body.

[0017] The heat insulation layer 9 fixedly arranged on the outer wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com