Bearing housing of an exhaust-gas turbocharger

A technology for bearing housings and exhaust turbines, applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve problems such as inconvenient, production geometry, and cumbersome design of bearing inserts, so as to reduce costs and reduce splash losses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

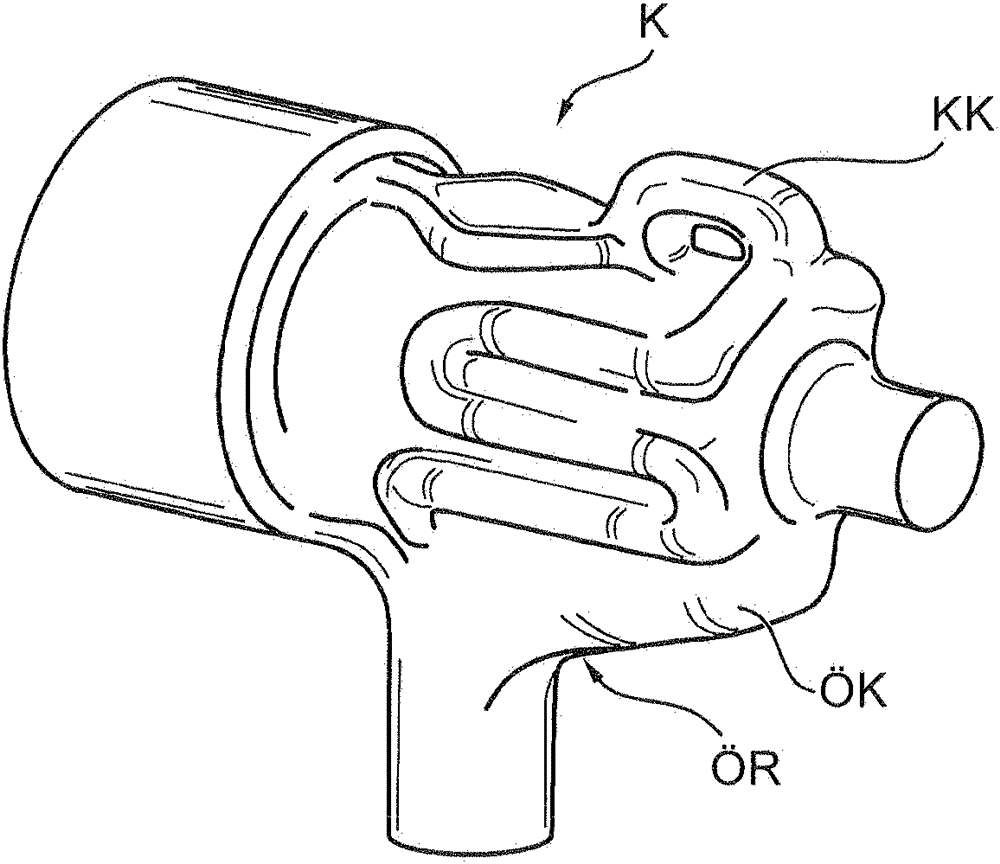

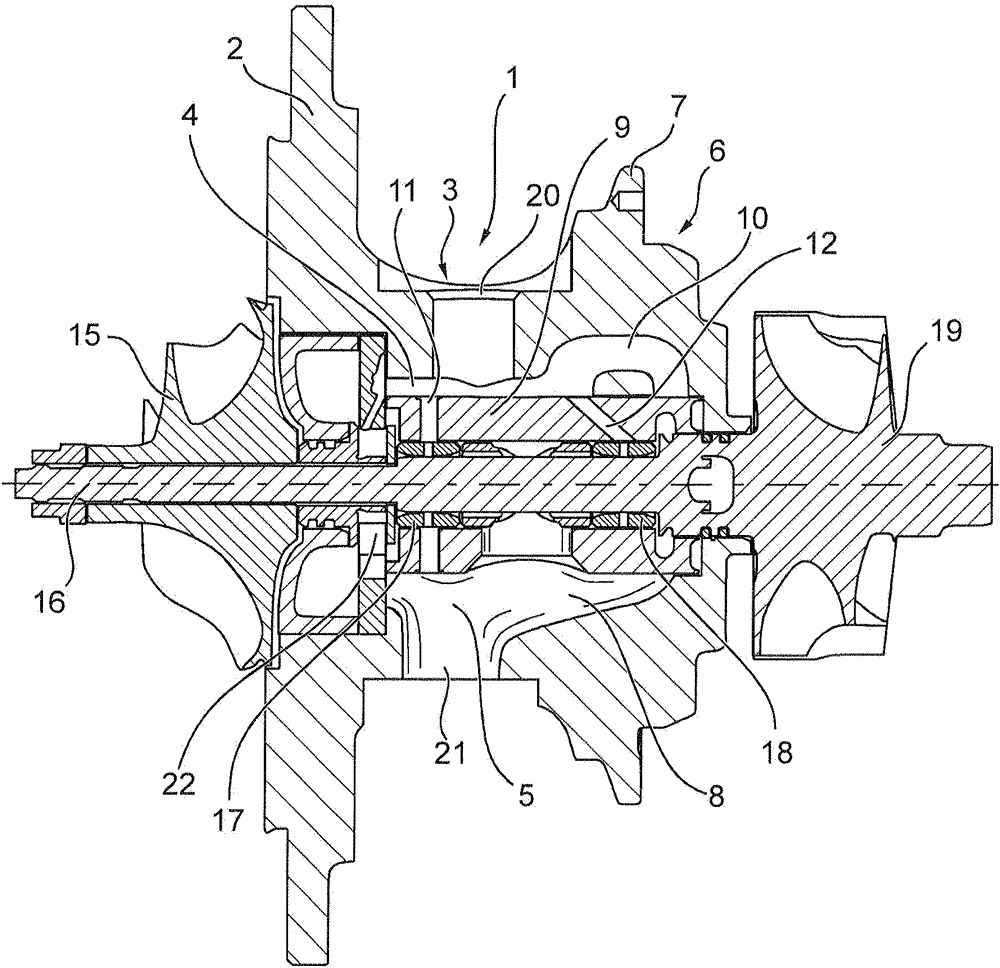

[0020] figure 1 An exhaust-gas turbocharger block set is shown, which has a bearing housing 1 according to the invention. The body pack also comprises a shaft 16, on one side of which the compressor wheel 15 is mounted and the turbine wheel 19 is mounted on the other side of the shaft, so as to form a rotor. The shaft 16 is mounted in the bearing housing 1 via a compressor-side bearing arrangement 17 and a turbine-side bearing arrangement 18 together with an axial bearing 22 . If a compressor housing and a turbine housing (they are in figure 1 not shown in ) is added to the body group, which creates an exhaust-gas turbocharger, so that the invention can also be described as an exhaust-gas turbocharger with a bearing housing 1 , the bearing housing will be described in detail below.

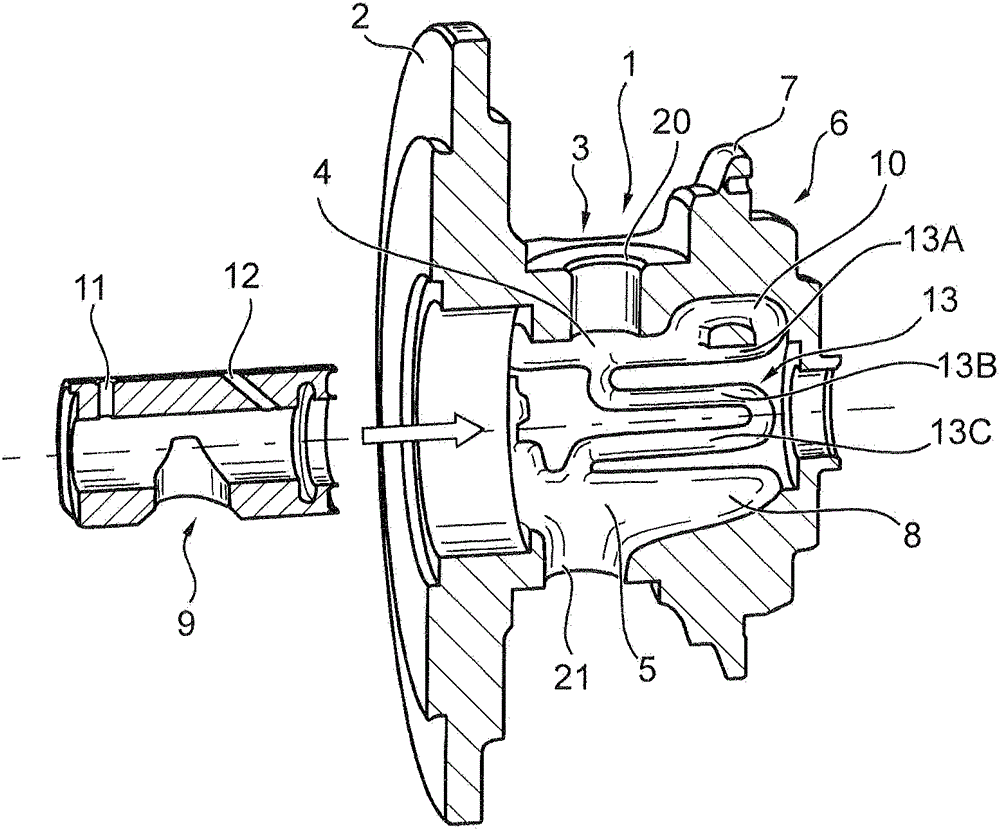

[0021] figure 2 The bearing housing 1 according to the invention is shown before a bearing sleeve 9 is inserted. The bearing housing 1 comprises: a compressor side housing flange 2; a centra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com