Asynchronous air-sweeping type flexible bionic retractable standing grain moving device

An air-blown, asynchronous technology, used in harvesters, agriculture, applications, etc., can solve the problems of large splash loss of grains, large direct impact of crop heads, and splashed grains, etc., to improve comprehensive operation efficiency and achieve continuous changes. , the effect of simple component structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

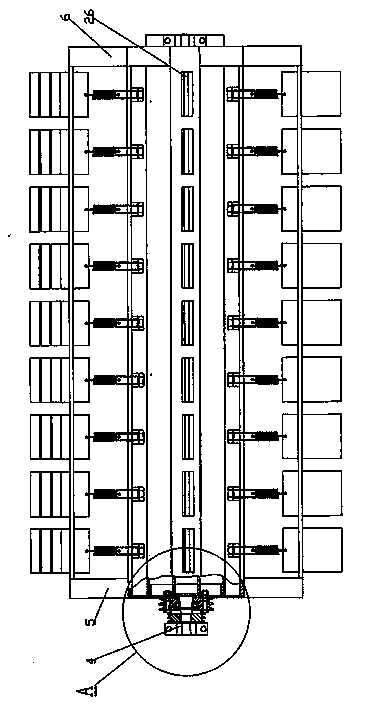

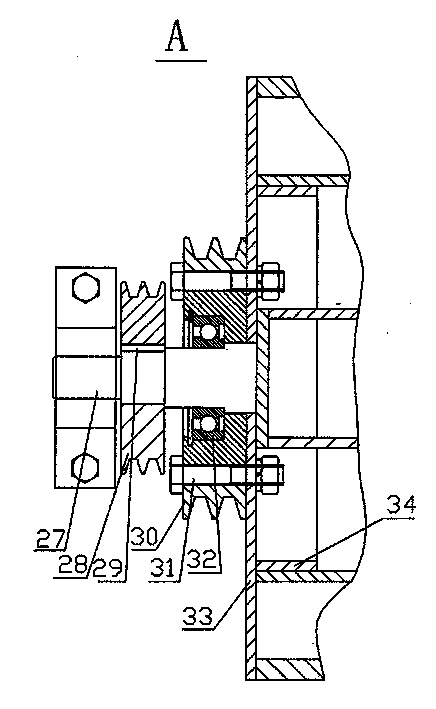

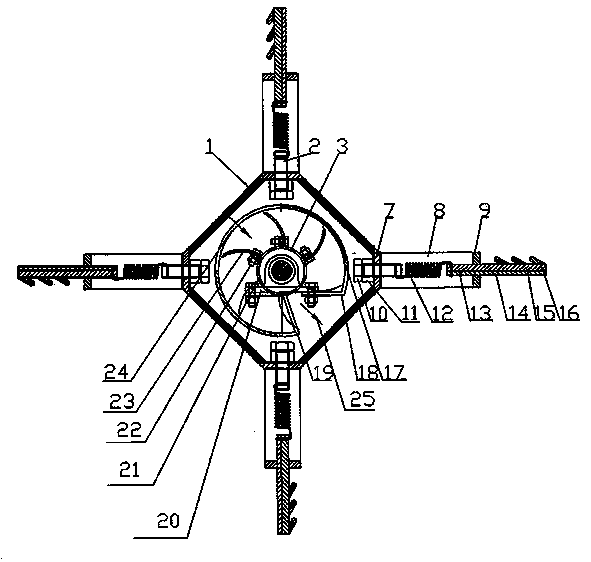

[0023] see figure 1 , figure 2 with image 3 As shown, it is composed of frame 1, bionic reeling mechanism 2, fan mechanism 3, and transmission mechanism 4. Inside the frame 1, the transmission mechanism 4 is located on the left side of the frame 1. It is characterized in that: the left frame 5 and the right frame 6 of the frame 1 are connected by the base 7, the column 8, and the limit plate 9, and the base 7 is equidistant in the horizontal direction. Distributed threaded holes are used to fix and adjust the bionic reeling mechanism 2, and the limit plate 9 distributes limit openings 26 at equal intervals in the horizontal direction; There is a hole in the middle, and the two ends of the spring 12 are respectively fixed in the opening of the bionic reeling mechanism 2 and the opening of the bionic reeling board 13, and a set nut 11 is installed between the positioning bolt 10 and the base 7, and the set nut 11 Together with the positioning bolt 10, the limit working stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com