a semiconductor laser

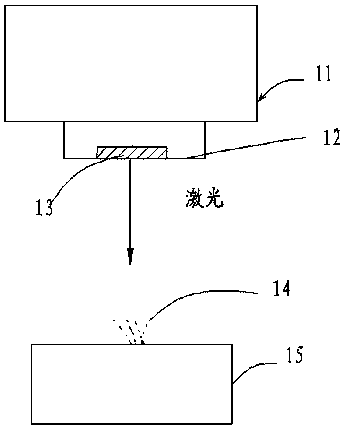

A laser and semiconductor technology, applied in semiconductor lasers, lasers, laser parts and other directions, can solve problems such as burning lasers and pollution, achieve the effect of easy purging, avoid pollution or damage, and achieve the effect of purging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to enable those skilled in the art to understand the technical solutions of the present invention more clearly, detailed descriptions will be given below in conjunction with the accompanying drawings and embodiments.

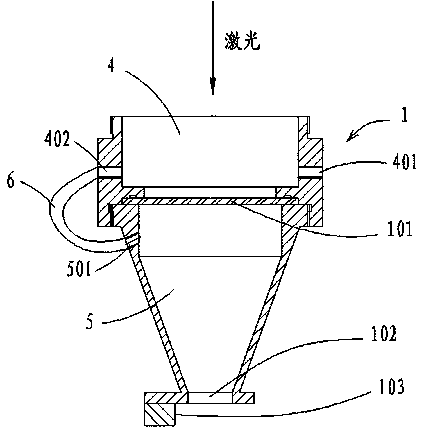

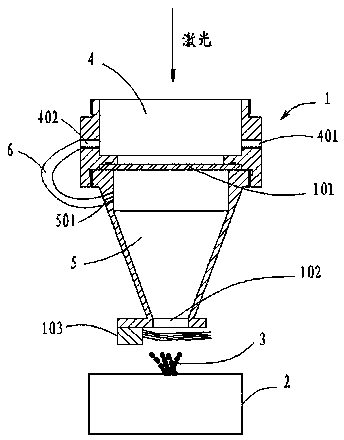

[0043] See figure 2 , figure 2 It is a schematic diagram of the composition of the laser head of the semiconductor laser according to the first embodiment of the present invention. exist figure 2 Among them, the laser head of the semiconductor laser includes a connection cover 1 , a secondary laser protective mirror 101 and a protective cone through hole 102 in sequence in the direction of laser emission. In the vicinity of the through hole 102 of the protective cone there is a gas purging device 103 . Both the secondary laser protective glasses 101 and the through hole 102 of the protective cone can pass through laser light, and the existence of the secondary laser protective glasses 101 prevents the primary protective lens of the laser he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com