Hot-rolled round steel for high-carbon-manganese-chromium grinding ball and manufacturing method thereof

A high-carbon manganese-chromium grinding ball and a manufacturing method technology, applied in the field of metal smelting, can solve the problems of high cost of composition design, low carbon content of wear-resistant cast steel, etc., and achieve the goal of increasing service life, improving wear resistance, and enhancing hardness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

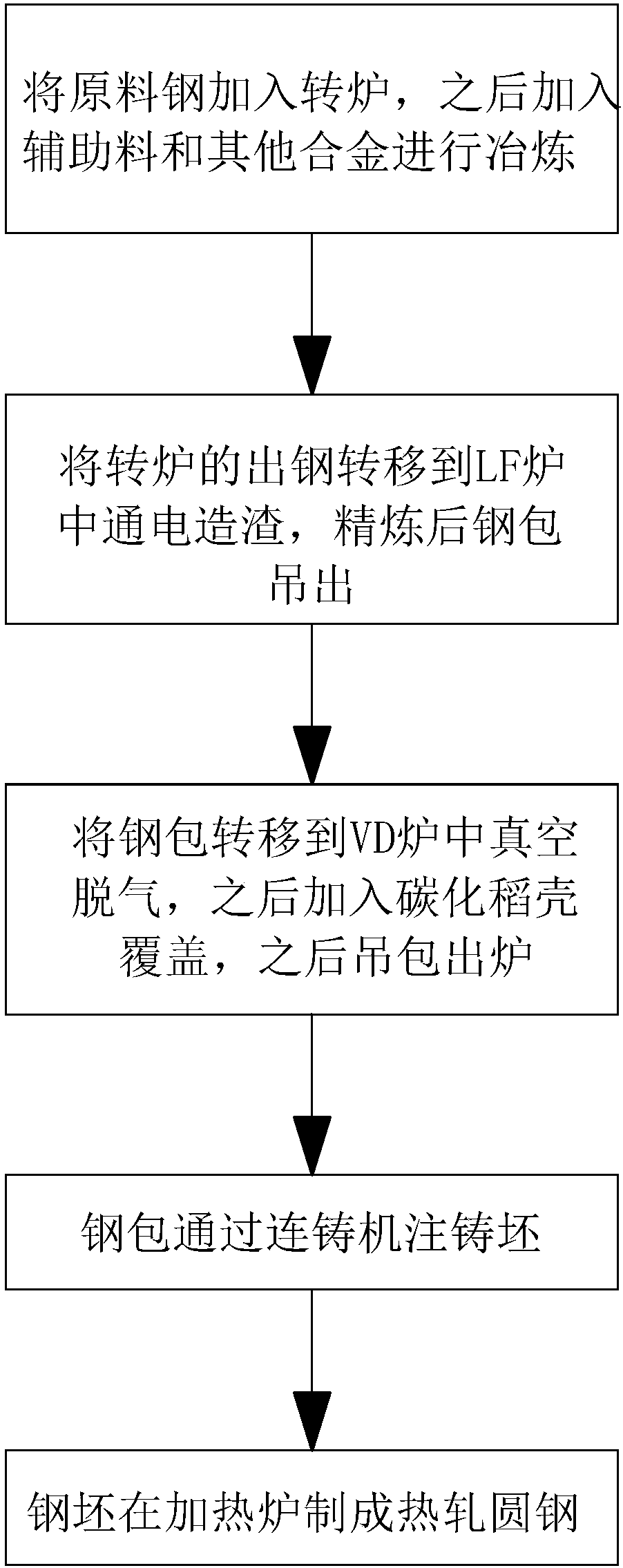

[0041] The following is attached figure 1 The present invention is described in further detail.

[0042] A method for manufacturing hot-rolled round steel for high-carbon manganese-chromium grinding balls, comprising the following steps:

[0043] Step 1: Add 110t steel containing 0.67 to 0.72% of C, 0.11 to 0.18% of Si, 0.70 to 0.80% of Mn, 0.45 to 0.55% of Cr, 0.019 to 0.021% of P and 0.100 to 0.120% of S in terms of mass percentage After smelting in the converter, artificial graphite, deoxidizer, carbon manganese, ferrosilicon, high carbon ferrochrome, silver, copper, indium, gallium, nickel, zinc and tin are added to the converter in sequence, and the whole process is blown from the bottom of the converter Add Ar, control the oxygen pressure ≥ 0.8Mpa, and the end point of smelting is C ≥ 0.16%, P ≤ 0.018%, the temperature of the molten iron reaches 1620-1645 ℃, and then the steel is tapped, and lime is added to the ladle. The amount of lime added It is 0.43-0.45% of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com