Catalyst for fuel cell and its fuel cell

A fuel cell and catalyst technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problem of low catalyst dispersion, achieve high dispersion, high active area, and reduce potential drop.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings.

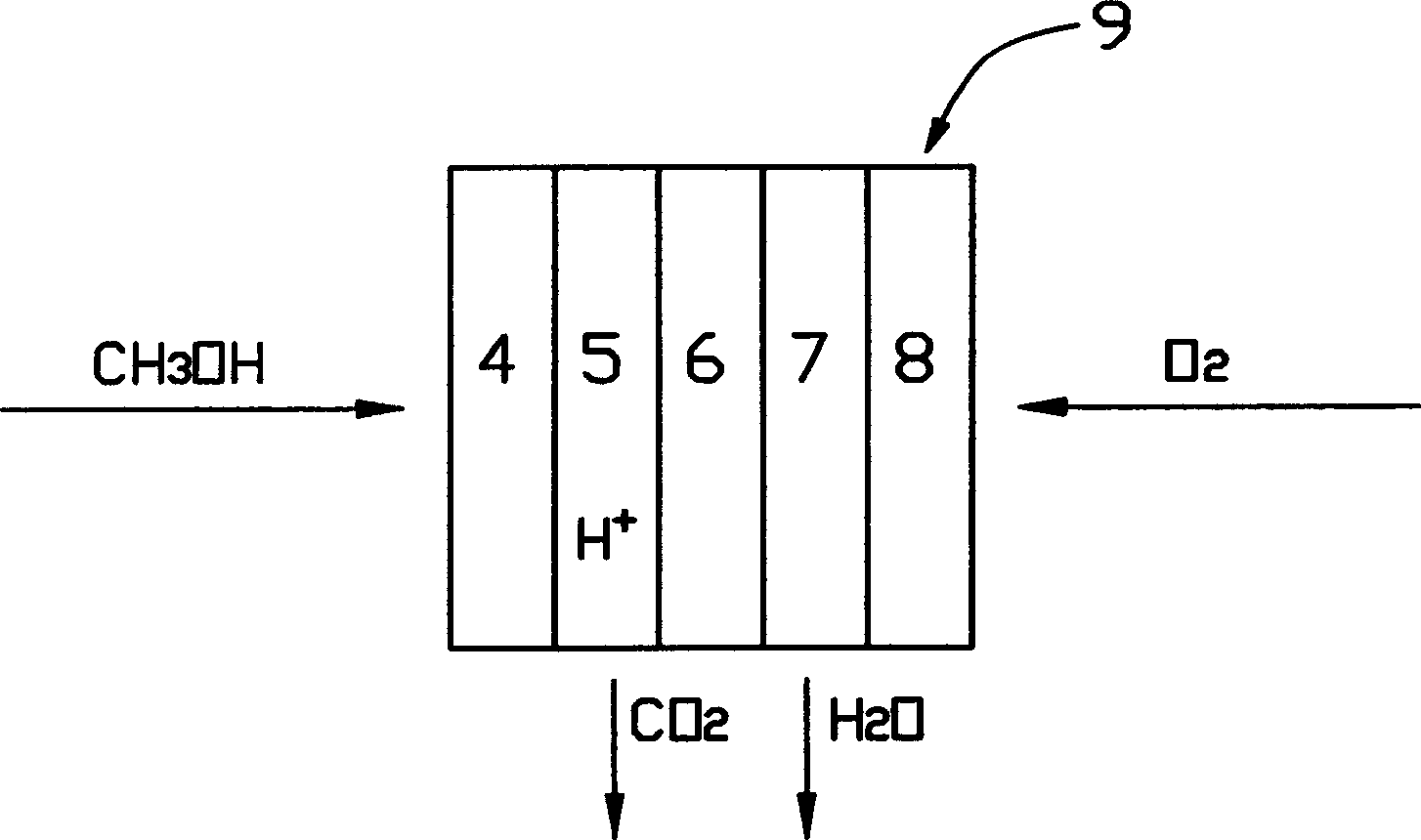

[0015] see figure 1 , the fuel cell 9 of the preferred embodiment of the present invention comprises gas diffusion layers 4 and 8, positive pole 5, negative pole 7, proton exchange membrane 6, wherein, proton exchange membrane 6 is positioned between positive pole 5 and negative pole 7, gas diffusion layer 4 and 8 are located outside the positive electrode 5 and the negative electrode 7 respectively.

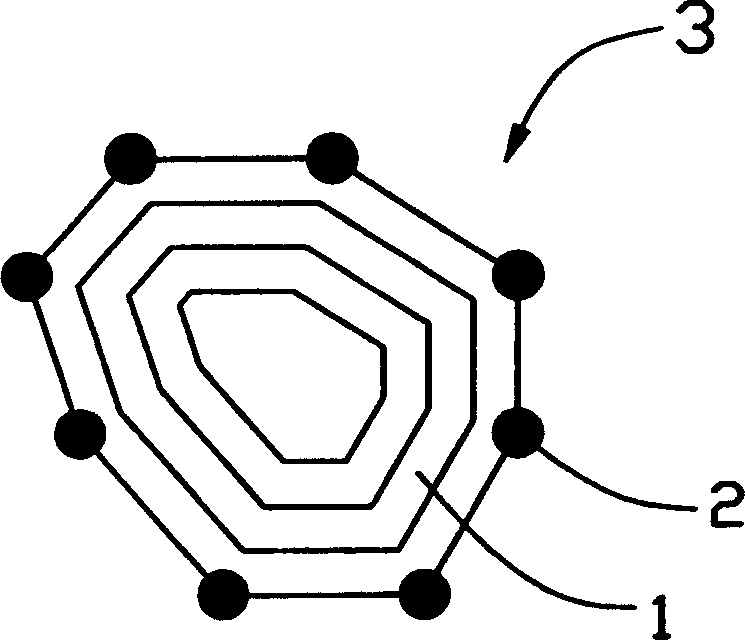

[0016] Please also see figure 2 , both the positive electrode 5 and the negative electrode 7 are composed of a catalyst 3, the catalyst 3 includes carbon nanospheres 1 and catalyst metal 2, and the catalyst metal 2 is atomically embedded on the corners or turning parts of the carbon nanospheres 1, in this embodiment, The catalyst metal 2 is metal platinum.

[0017] Nano-carbon sphere 1 is a polyhedral carbon cluster composed of multilayer graphite layers wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com