Thread feeding device comprising spring stop for thread detecting

A technology for stopping devices and feeding devices, which can be used in transportation and packaging, textiles and papermaking, weft knitting, etc., and can solve problems such as weakening of the function of yarn feeding devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

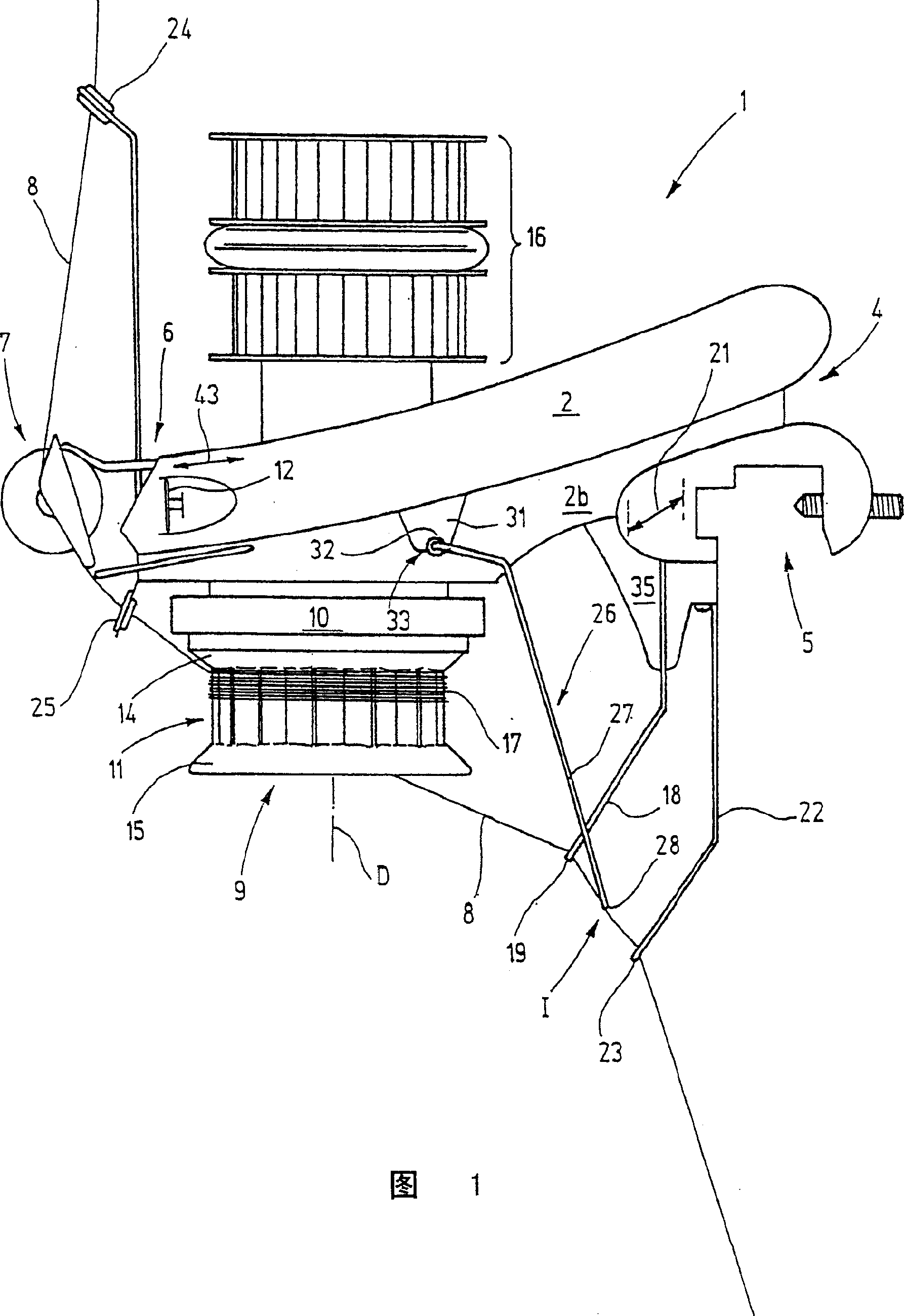

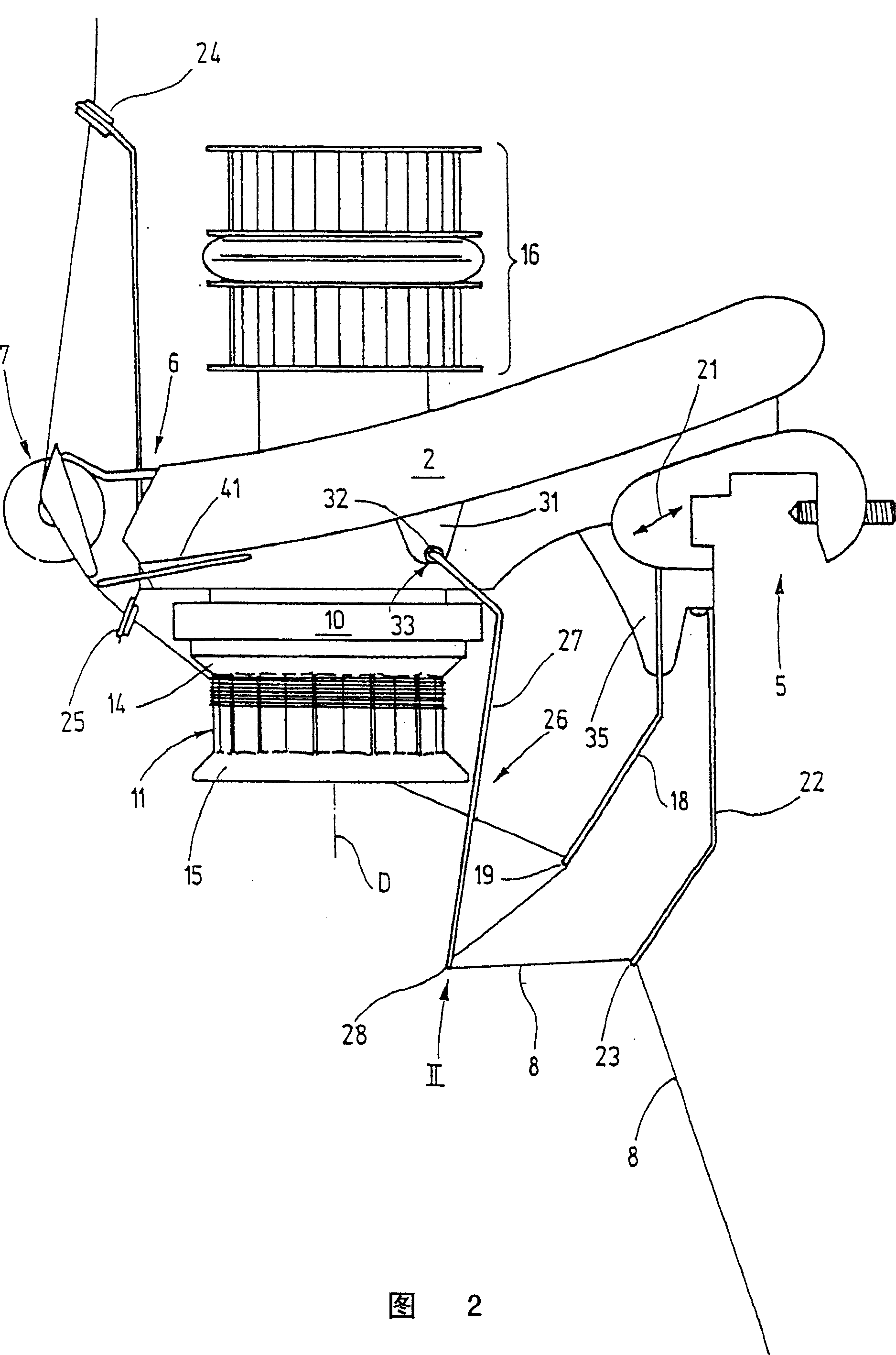

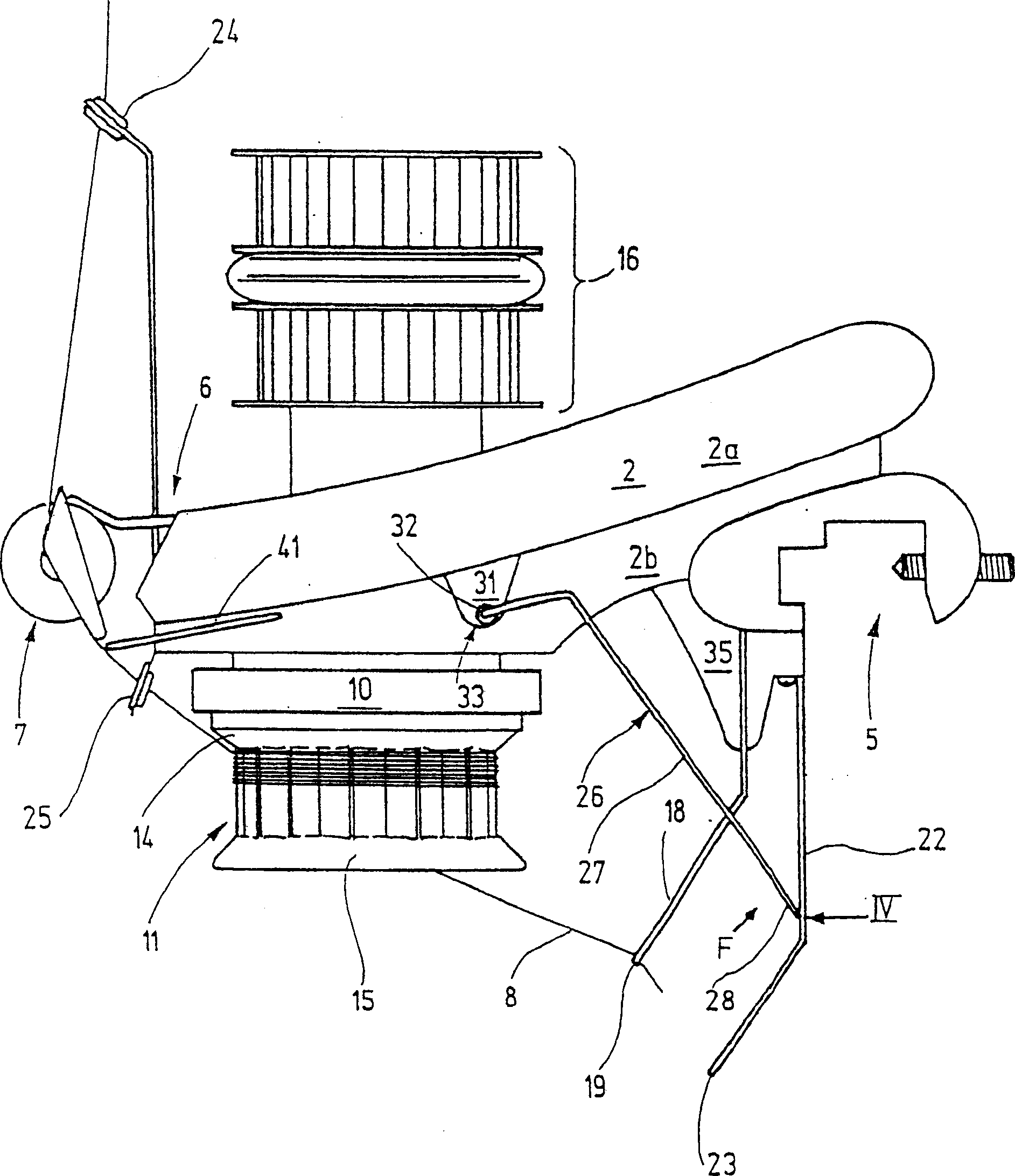

[0028] In Fig. 1, a yarn feeding device 1 is shown, the housing 2 of which acts as a central support. At one end 4 it is provided with a fastening clip 5 for fastening to a knitting machine or similar thread using machine, while at the opposite end 6 a thread stopper 7 is arranged. This yarn stop stops the yarn 8 running past it by non-positive engagement.

[0029] Between the ends 4, 6 there is a vertical shaft rotatably supported on the housing 2 about the axis of rotation D, and at its lower end there is a yarn feeding wheel 9 which has a ring at the top 10. This ring is preferably a deep elongated sheet metal part. The outer peripheral surface 11 of the sheet metal part is closed and shaped, while the upper and lower edges 14, 15 are each tapered. One or more pulleys 16 are used to drive the yarn feed wheel 9, the pulleys 16 above the housing 2 being connected to the shaft.

[0030]The yarn feeding wheel 9 forms a kind of advancing device for feeding the yarn 8 accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com