Flash lamp unit

A flash device and flash light-emitting technology, applied in lighting devices, light sources, optics, etc., can solve the problems of uneven light distribution and insufficient light quantity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0015] First, a first embodiment of the strobe device of the present invention will be described.

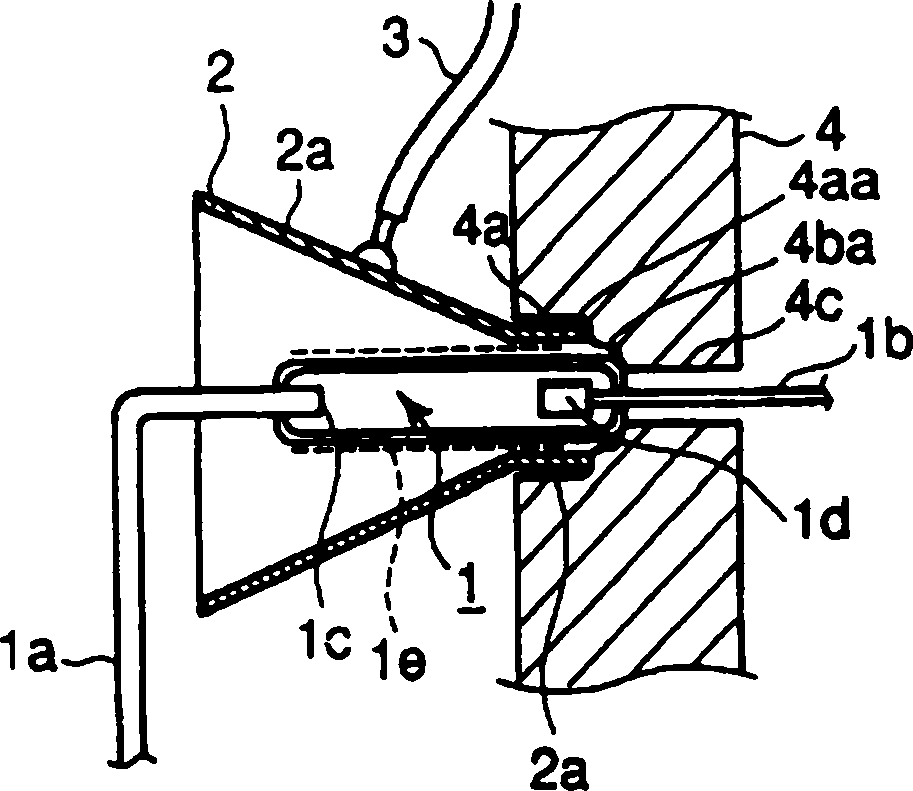

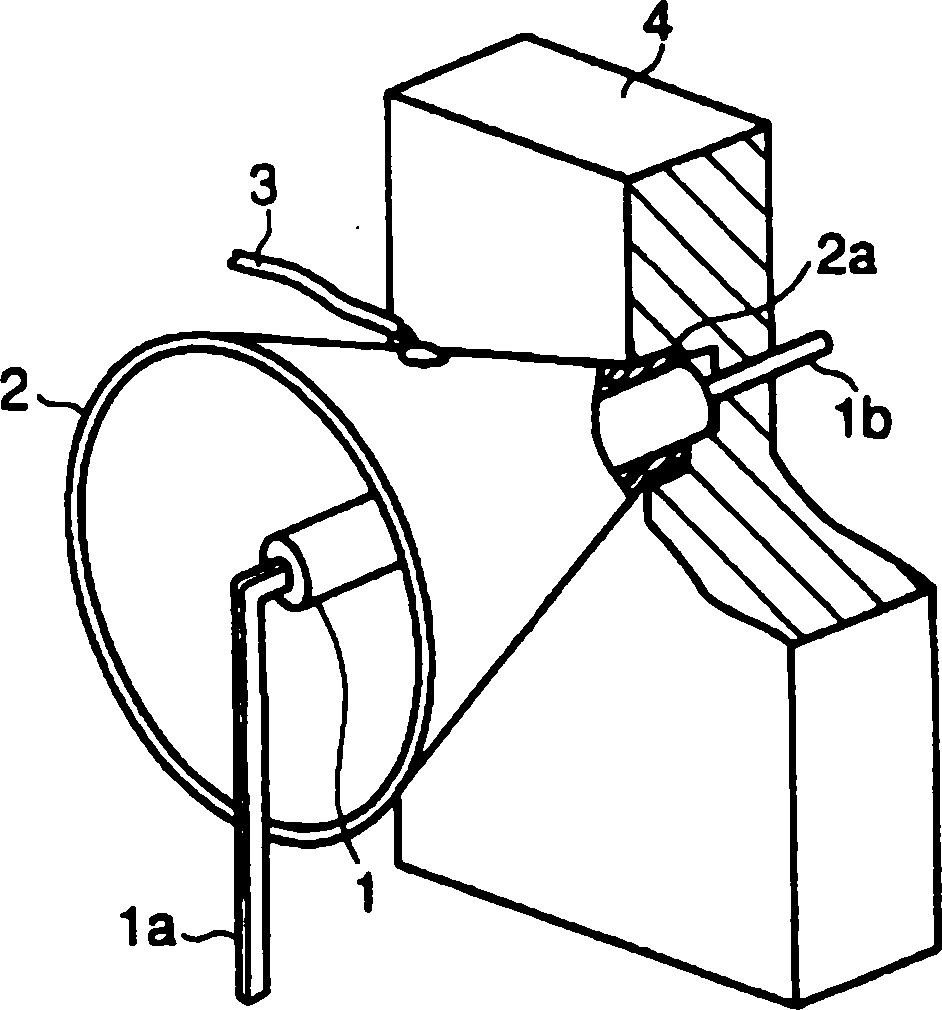

[0016] figure 1 It is a sectional view showing the structure of the strobe device of the present invention. figure 2 It is a perspective view showing the light emitting part of the strobe device in partial cross section.

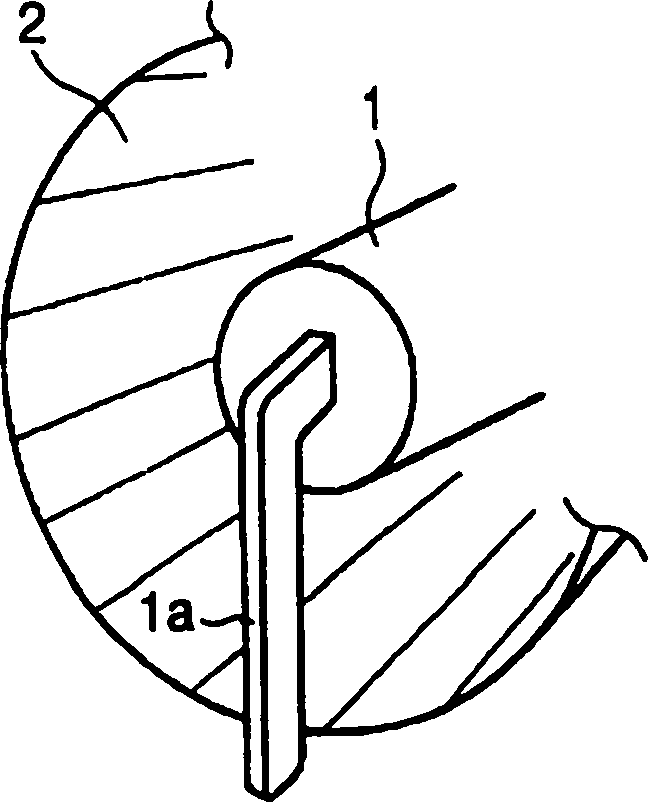

[0017] A xenon tube 1, which is a flash discharge tube, has xenon gas enclosed therein, and has terminals 1a and 1b extending outward from both ends thereof. The terminal 1a is formed to extend toward the direction of light irradiation, and the terminal 1b is formed to extend toward the fixing member 4 of the main body. The terminal 1a is bent at a substantially right angle with respect to the xenon tube 1, and is electrically connected to an unillustrated lead wire or a substrate. On the other hand, the terminal 1b extends linearly with respect to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com