Phase gradient metasurface antenna of microstrip-line-like feed structure

A technology of microstrip line feeding and phase gradient, which is applied in the direction of antenna grounding switch structure connection, antenna, antenna grounding device, etc., can solve the problem that the metasurface antenna cannot take into account low profile and high performance, and achieve high degree of freedom and enhanced Orientation, the effect of realizing the degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific examples.

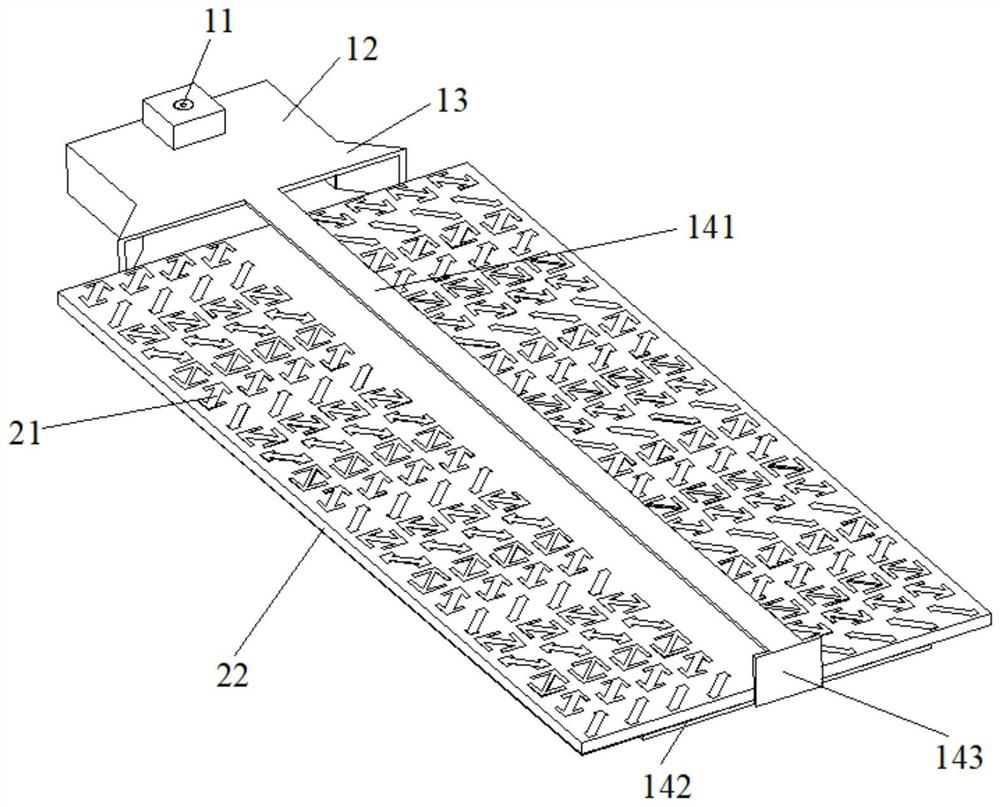

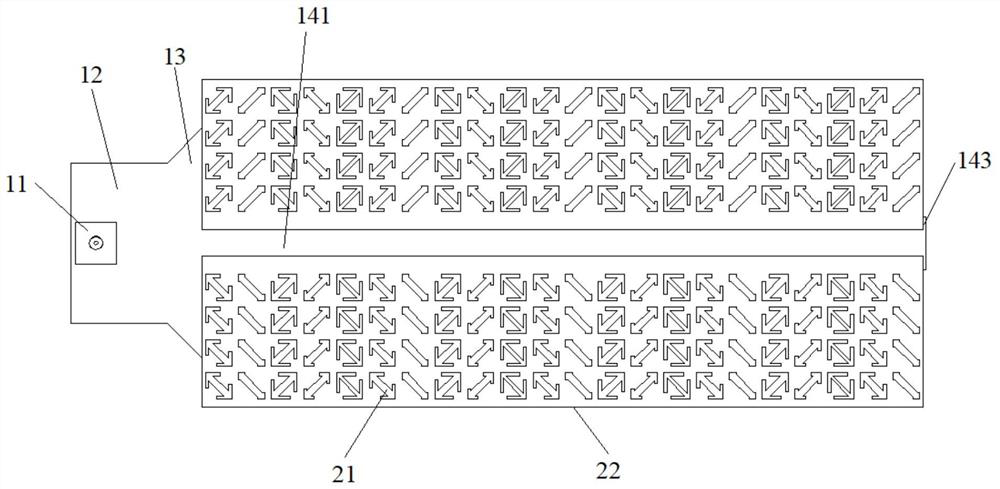

[0029] refer to Figure 1 to Figure 4 , a phase gradient metasurface antenna similar to a microstrip line feed structure, which consists of two parts: a microstrip line feed structure and a radiator of a phase gradient metasurface.

[0030] The microstrip-like feeding structure includes an SMA coaxial connector 11, a rectangular waveguide 12, a horn waveguide 13 and a similar microstrip line. The rectangular waveguide 12, the horn waveguide 13 and the quasi-microstrip line are all made of metallic copper. Both the rectangular waveguide 12 and the horn waveguide 13 are hollow cavity structures with closed upper and lower side walls and front and rear side walls. The left side wall of the rectangular waveguide 12 is closed, while the right side wall is opened. The left s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Opening angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com