Conical pen point and its manufacturing method and ceramic composite conical pen point

A ceramic composite and conical technology, applied in the direction of nibs, printing, writing utensils, etc., can solve the problems of complex metal molds, high cost of metal molds, and inability to confirm, so as to reduce production costs, facilitate dimensional accuracy, and prevent defective products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

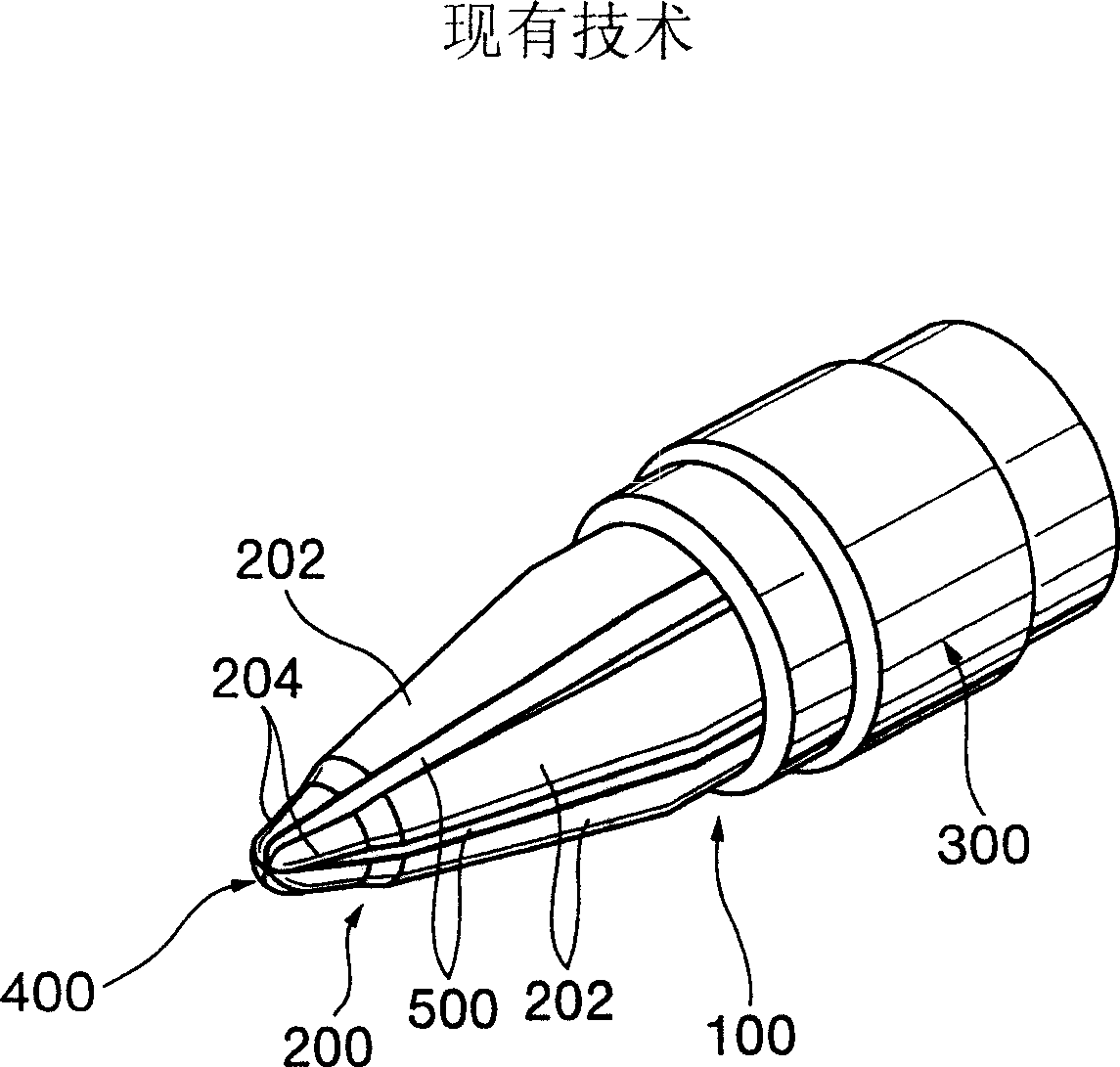

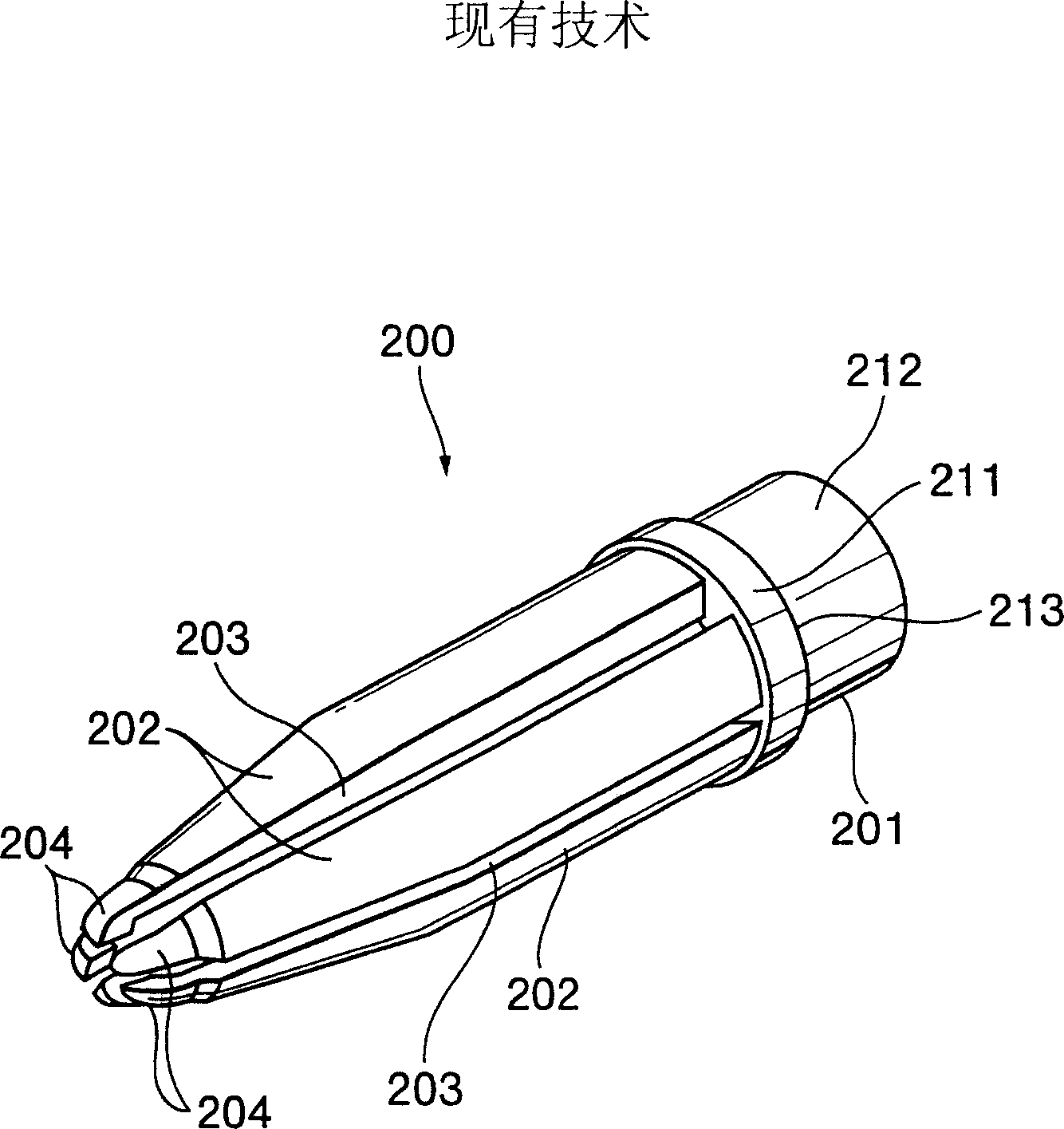

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The first implementation type

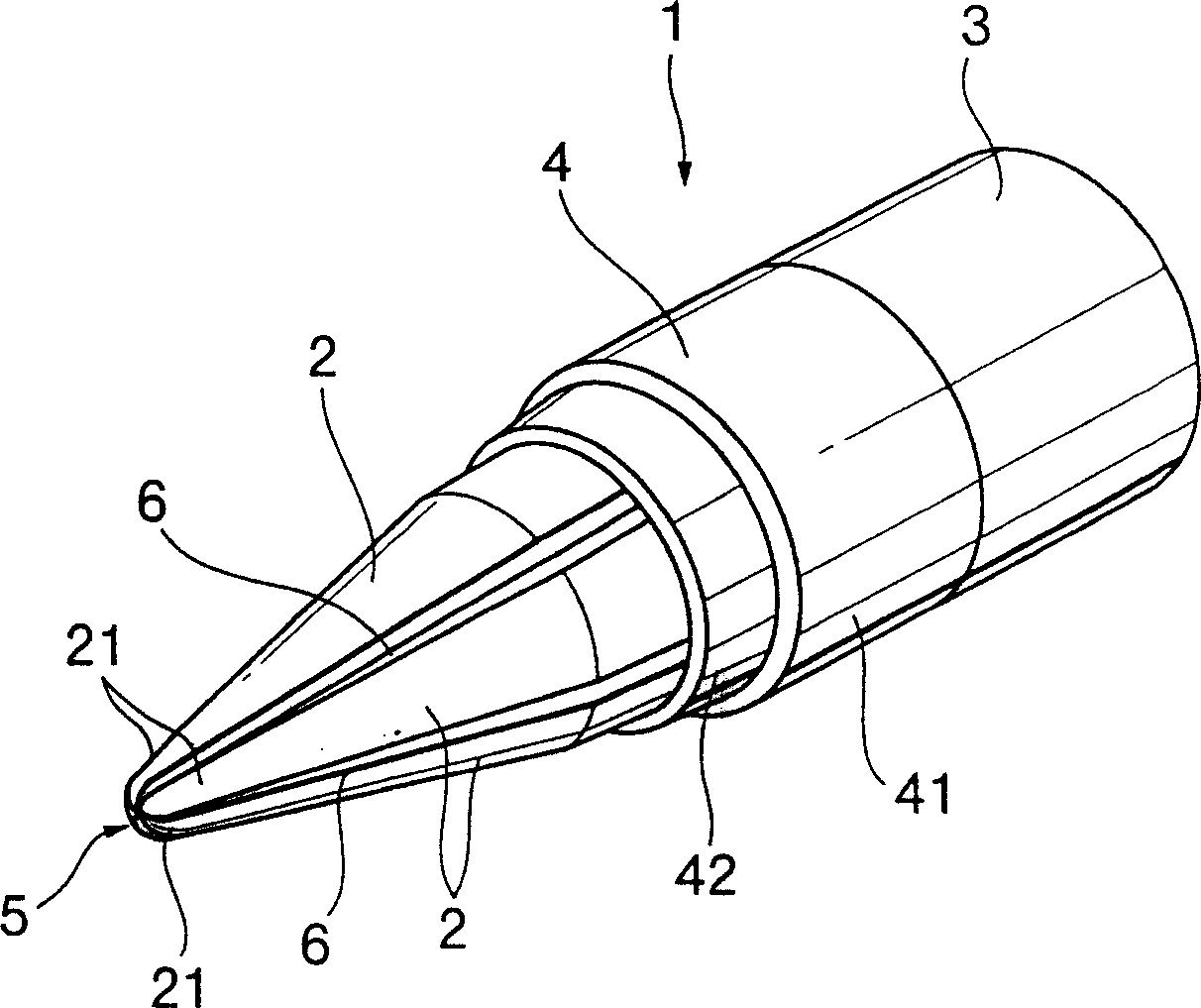

[0069] Hereinafter, embodiments of the present invention will be described with reference to the drawings. image 3 A perspective view of a conical nib related to the first embodiment of the present invention. exist image 3 Among them, 1 is a conical nib (hereinafter simply referred to as nib), which includes a plurality of comb-toothed pieces 2, 2...maintaining member 3 and converging member 4; the shape of the conical nib is formed in the following manner: The one-piece comb-toothed piece 2 is combined by the maintaining member 3 and the converging member 4 , and has a pen end 5 at the tip, and ink outlet passages 6 are included between the plurality of comb-toothed pieces 2 .

[0070] The apexes of the multiple pectine-shaped sheets 2, 2... are slightly hemispherical, and the whole can gradually converge into a slightly conical shape toward the apex. As shown in Figure 4 (a), the comb-toothed sheets 2, 2... of multiple sheets are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com