Method of producing paper or paperboard and paper maker or paperboard maker

A technology for paper machines and cardboard machines, applied in the directions of paper machines, paper machines, wet ends of paper machines, etc., can solve the problems of paper breaking running capacity, increase machine length and investment costs, increase the demand for drying energy, etc., and achieve savings. Equipment cost, reduced number of breakages, increased density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

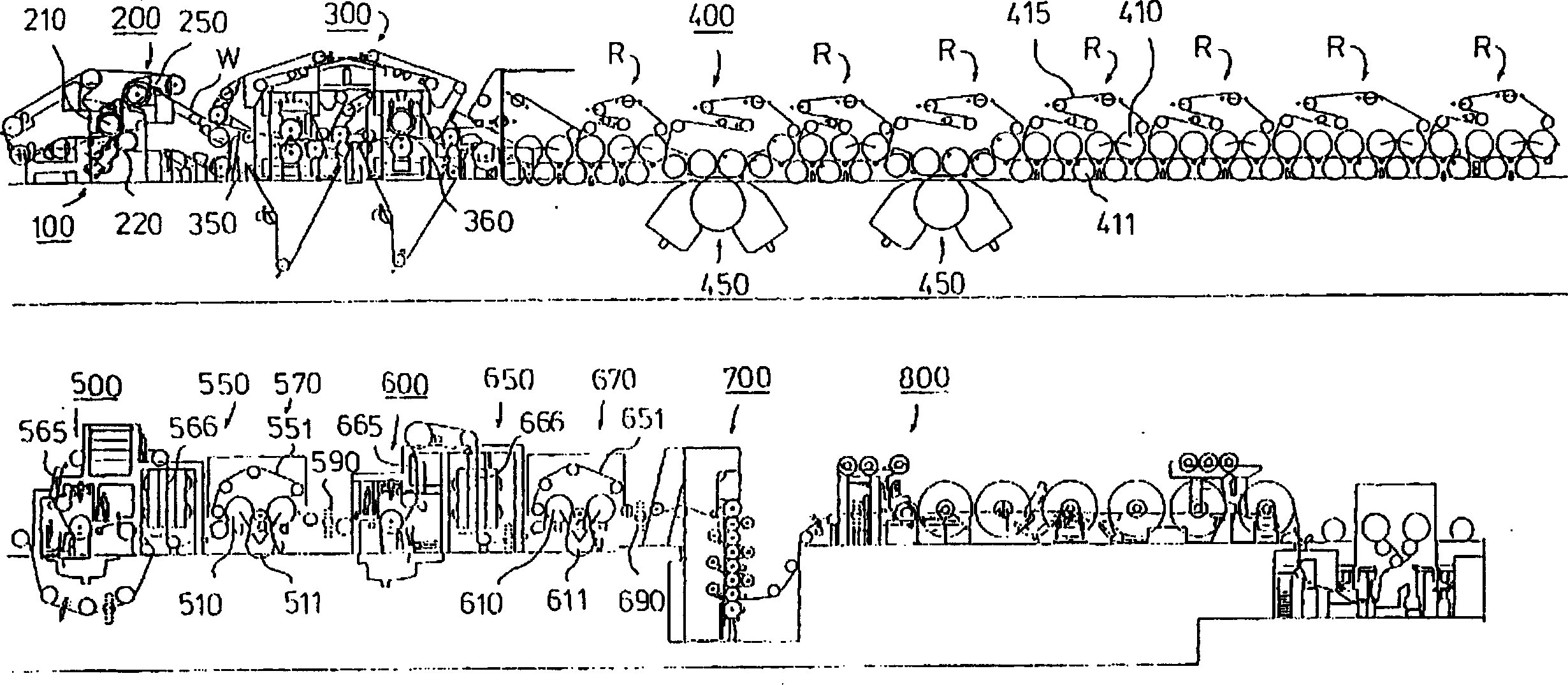

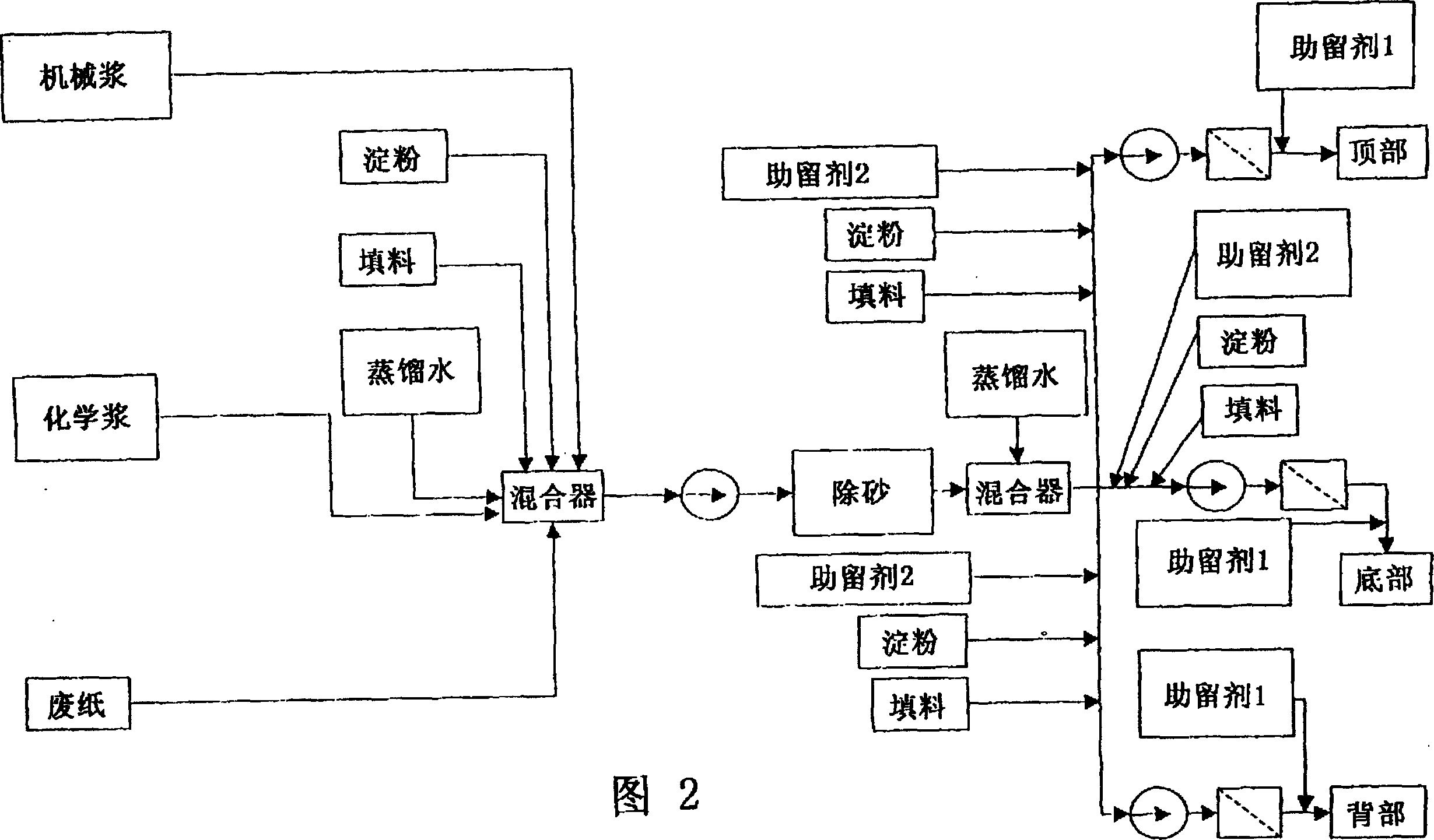

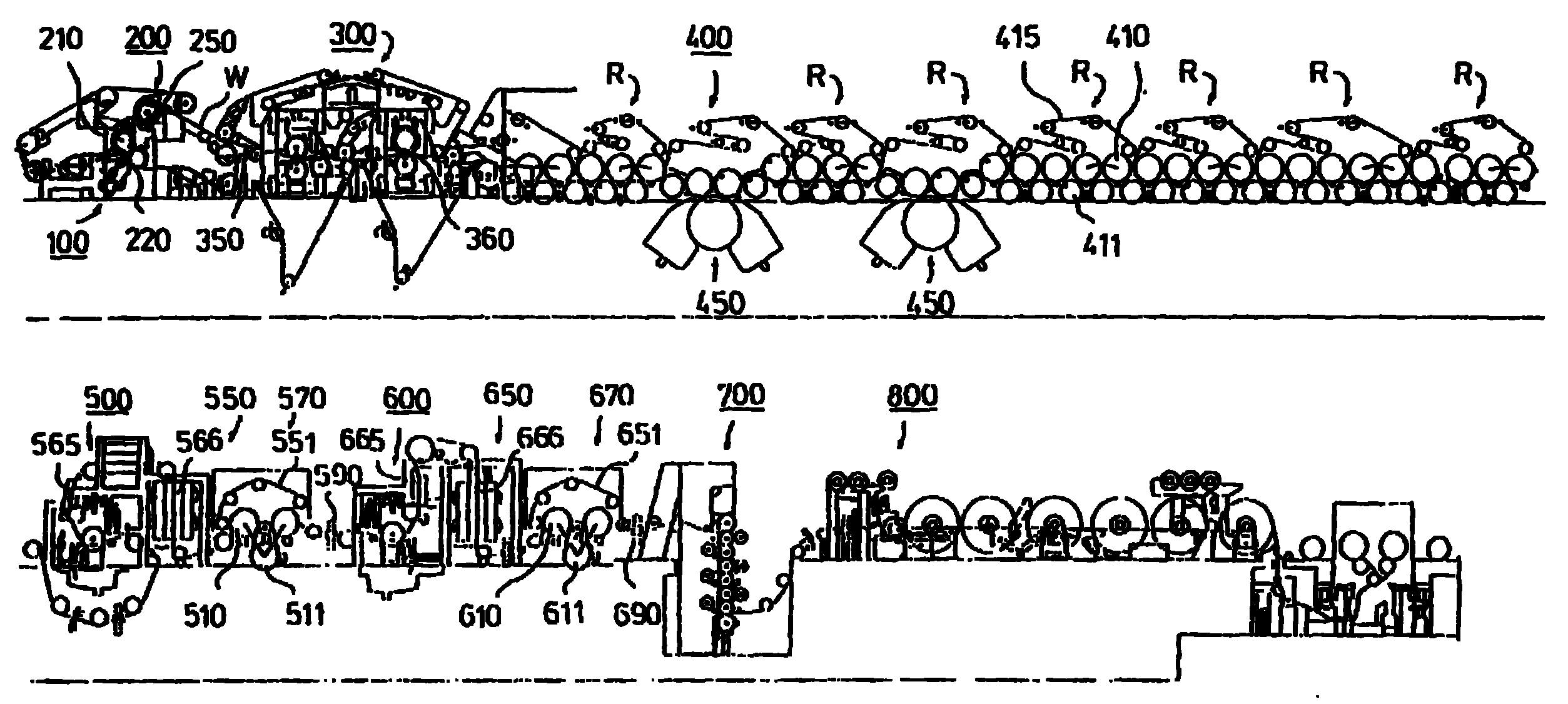

[0048] Such as figure 1 As shown, the stock is sent from the headbox 100 to the wire section 200, with a gap former 250 dewatering from both sides, followed by a press section 300. In the press section 300, at least one press is in the extended nip, preferably a shoe press, to preserve bulk and reduce double-sidedness during dewatering of the sheet. In the press section as shown, the first nip is a roll nip 350 and the second nip is an extension nip 360 . The web W passes from the press section 300 to the dryer section 400, using a single wire draw R and impingement dryer 450 in the application shown. The web W is coated by a coating section 500,600 and then dried by passing through a drying section 550,650 with basic infrared dryers 565,665 and air cushion dryers 566,666. This non-contact drying section 550, 650 is followed by a short cylinder group 570, 670, where the drawing and tensioning of the paper is done while drying the paper. After this, the paper is calendered a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com